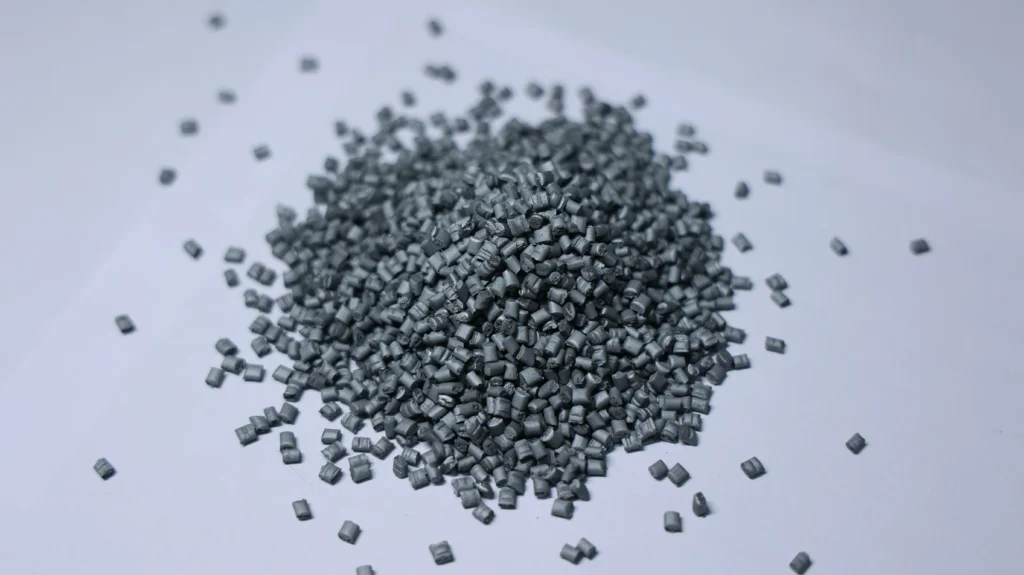

Antioxidant Masterbatch

Antioxidant masterbatch is a functional masterbatch that uniformly disperses antioxidant additives within a thermoplastic resin carrier. When plastics are exposed to heat, light, or oxygen, oxidative reactions occur, leading to molecular chain breakage, cross-linking, or degradation. This antioxidant masterbatch effectively inhibits oxidative degradation during plastic processing and use, thereby extending the service life of plastic products.

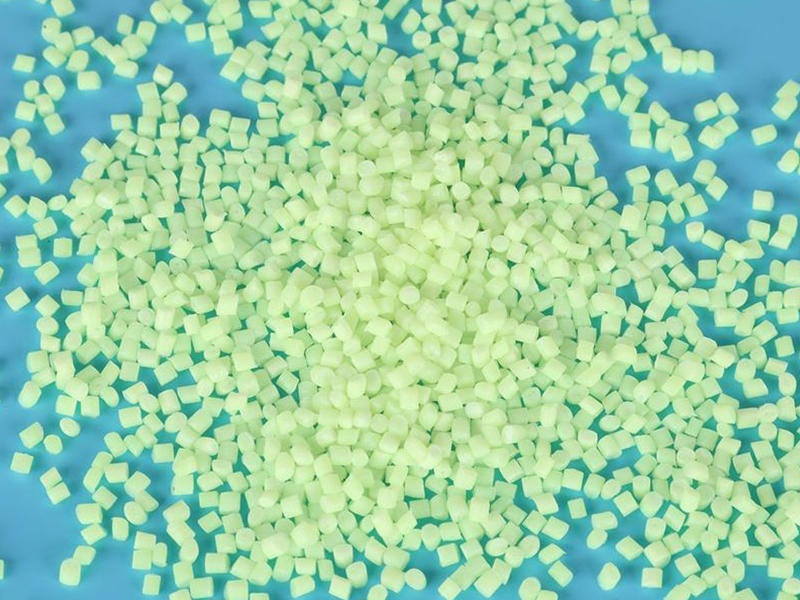

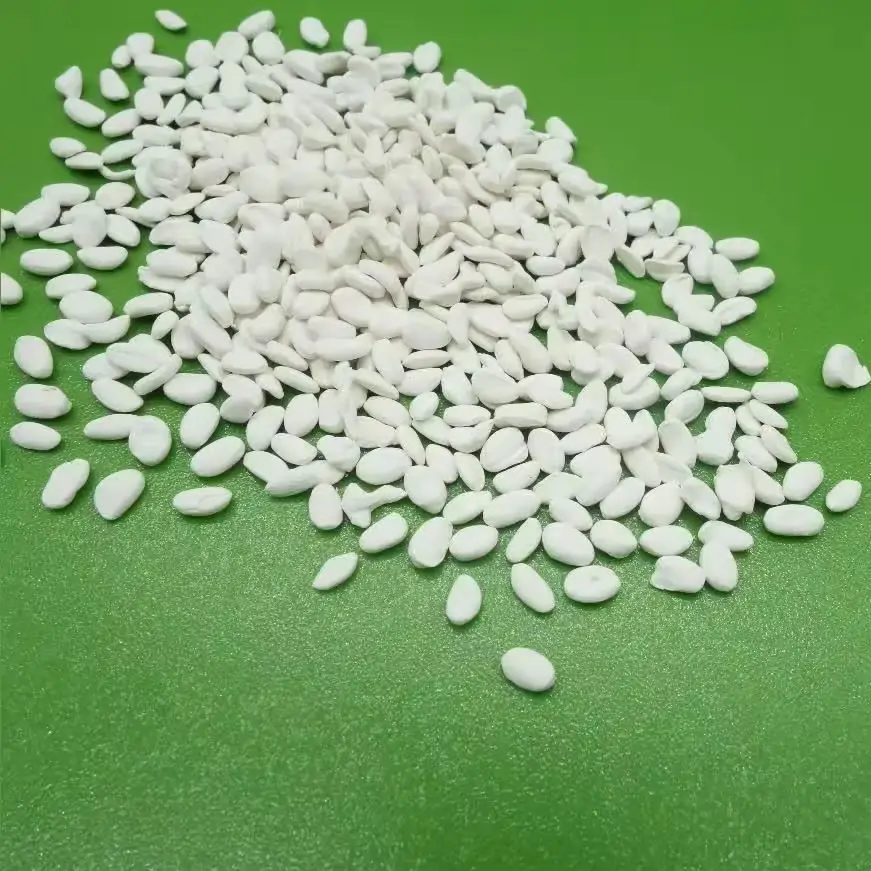

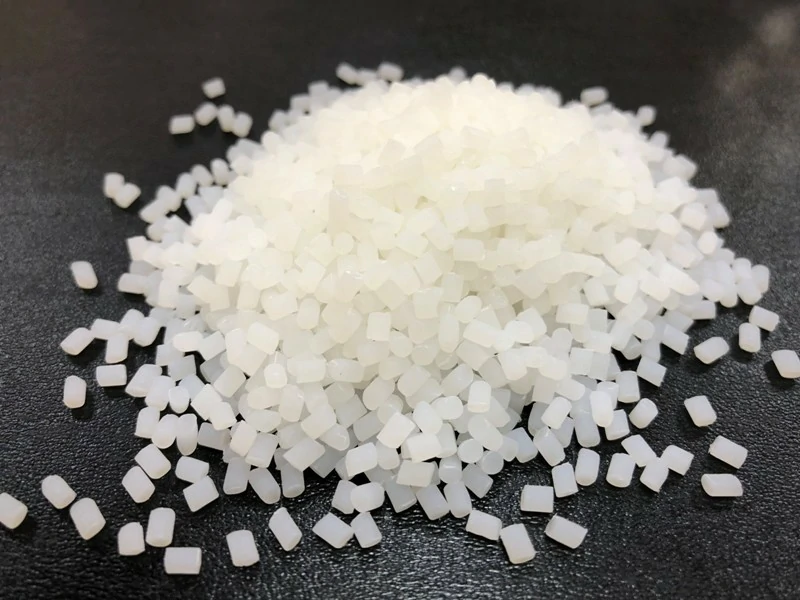

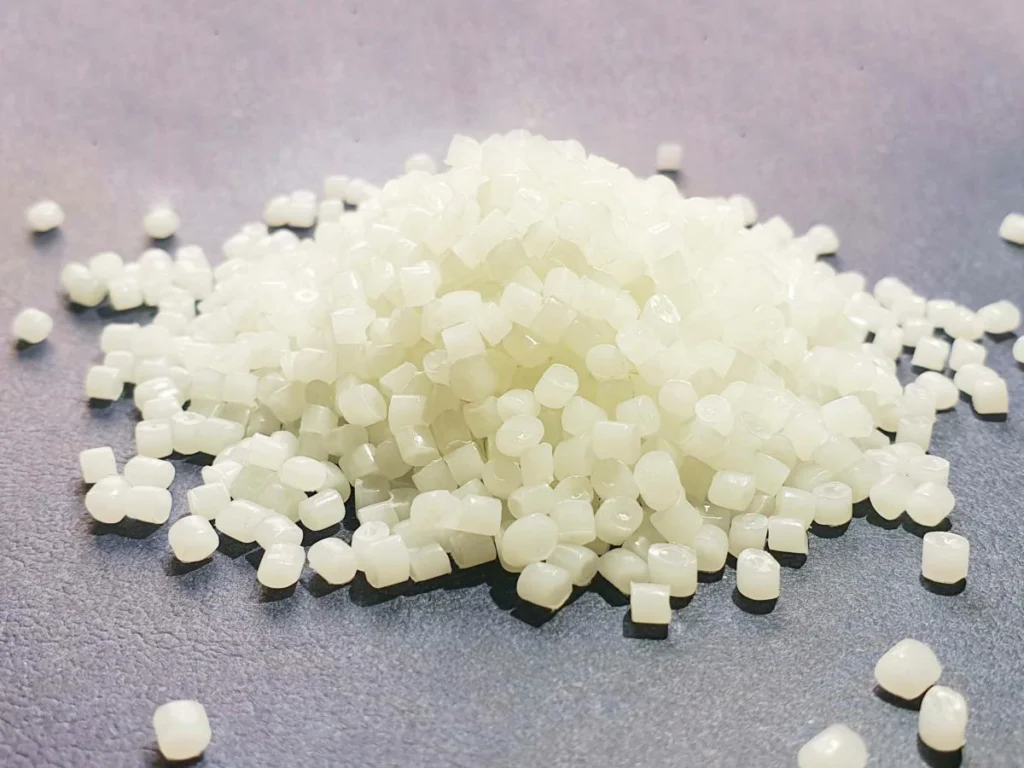

- Colour: Black antioxidant masterbatch, white antioxidant masterbatch, transparent antioxidant masterbatch, and standard colours are available. Samples may also be provided, or custom colours tailored to your specifications using the Pantone colour chart.

- Suitable Substrates: PE, PP, ABS, PET, PS, TPU, PA, etc.

- Dispersants: Polyethylene wax, oxidised polyethylene wax, stearate, EBS lubricant

- Suitable Plastic Processing Methods: Injection moulding, extrusion, blow moulding, cast film extrusion, fibre spinning and other processes, etc.

- Package: 25KG/BAG, 26 tons per 20ft container.

- Leadtime: 7 days after order confirmed.

- Payment Terms: T/T,, L/C.

aDVANTAGES

Antioxidant masterbatch solutions for enhanced durability, vibrancy and efficiency in plastics

Extending product lifespan

Our antioxidant masterbatch possesses the capability to delay the ageing of plastic products, extending their service life by 2 to 5 years compared to plastic products without antioxidant properties.

Preserving product colour

Our antioxidant masterbatch mitigates the risk of colour oxidation and degradation, ensuring colours remain unchanged for longer.

Convenient to use

We simply need to incorporate a specified proportion during the plastic manufacturing process to obtain uniformly dispersed plastic products with antioxidant properties.

Stability during storage

During production, the dispersion temperature range for antioxidants in the masterbatch is 180°C to 300°C, thereby maintaining its stability throughout the processing of thermoplastic materials.

Suitable for multiple processing techniques

Widely applied in injection moulding, extrusion, blow moulding, cast film production, fibre spinning and other processes.

Cost-effective

By reducing uneven distribution and waste of antioxidants while imparting antioxidant properties to plastic products, it gains a more competitive edge in the masterbatch antioxidant market.

Specifications

| Product name | Antioxidant Masterbatch |

|---|---|

| Melt Index | 2-20 g/10min |

| Dispersion Temperature | 180-300°C |

| Antioxidant Content | 10-40% |

| Moisture Content | <0.1% |

| Density | 0.92-1.25 g/cm³ |

| Recommended Addition Rate | 1-3% |

| Density | 0.90–1.05 g/cm³ (varies by carrier) |

| Heat Resistance | Stable at 260°C for short-term processing |

Customized Antioxidant Masterbatch

Huashuo can customize Antioxidant color masterbatches according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, ABS, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

Tailored Antioxidant Masterbatch Solutions for Every Industry

| Industry | Carrier Resin | Loading (%) | Application Fields |

|---|---|---|---|

| Automotive | PP / PA / ABS | 0.5–1.5 | Bumpers, interior parts, under-the-hood components |

| Packaging | PE / PP / PET | 0.3–1.0 | Food packaging, bottle caps, shrink films, turnover boxes |

| Construction | PVC / PE / PP | 0.8–2.0 | Pipes, roofing membranes, insulation materials, profiles |

| Agriculture | LDPE / LLDPE | 1.0–2.0 | Mulch films, irrigation pipes, greenhouse coverings |

| Electronics | ABS / PC / PS | 0.5–1.2 | Housings, connectors, insulating materials, cable sheaths |

| Medical Devices | PP / PC | 0.3–0.8 | Syringes, infusion equipment, medical device housings |

“Types of Antioxidant Masterbatch ”

”

Three antioxidant masterbatch types to tackle outdoor ageing and fading

Primary Antioxidant Masterbatch

Also known as free radical scavengers, these agents react with free radicals generated during oxidation, thereby terminating the chain reactions responsible for plastic degradation. Common primary antioxidants include hindered phenols such as BHT, 1010, and 1076.

Secondary Antioxidant Masterbatch

Also known as peroxide scavengers, these agents convert peroxides into non-reactive compounds, thereby preventing further degradation. Typical secondary antioxidants include phosphites (such as 168) and DLTP.

Synergistic Antioxidant Masterbatch

This type combines primary and secondary antioxidants in a single masterbatch, leveraging their synergistic effects to provide comprehensive protection against oxidation. It is the most popular choice in the masterbatches antioxidant market due to its convenience and superior performance for long-term outdoor or high-temperature applications.

antioxidant Masterbatchs in Plastic

Food Packaging

Food Packaging Daily Chemical

Daily Chemical Plastic Molded Products

Plastic Molded Products

Plastic Pipe

Plastic Pipe Wire And Cable

Wire And Cable

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.