Flame Retardant Masterbatch

Flame retardant masterbatch, commonly referred to as flame retardant additive masterbatch, is a highly concentrated functional plastic masterbatch. When incorporated into plastic product manufacturing at specified ratios, it yields finished plastic goods capable of effectively suppressing or delaying combustion, preventing flame propagation, and reducing the release of toxic and harmful gases during burning.

- Colour: Black, white, transparent, coloured, with customisation available to Pantone colour charts or by sample submission.

- Suitable Substrates: PE, PP, ABS, PS, TPU, PA, etc.

- Dispersants: Polyethylene wax, stearic acid derivatives, EBS (Ethylene Bis Stearamide), etc.

- Suitable Plastic Processing Methods: Injection moulding, extrusion, blow moulding, film production, fibre production, etc.

- Package: 25KG/BAG, 26 tons per 20ft container.

- Leadtime: 7 days after order confirmed.

- Payment Terms: T/T,, L/C.

aDVANTAGES

Choose Huashuo flame-retardant masterbatch, where safety and quality go hand in hand.

Enhanced flame-retardant properties

Effectively halts flame propagation within 10 seconds, with no flammable cotton-igniting droplets, meeting international flame-retardant standards (UL94 V0/V1, GB/T 2408).

Excellent dispersion properties

Professional formulation and production processes ensure the uniform and stable distribution of flame retardants throughout plastic products. Compared to direct addition of flame retardants, this reduces agglomeration and prevents areas of the plastic product from lacking flame retardant effectiveness.

High thermal stability

Thermal decomposition temperature ≥280°C. Does not decompose at thermal processing temperatures and does not react with other plastic additives (such as antioxidants or colourants). Suitable for all conventional thermoplastic materials without compromising mechanical properties.

Convenient application

Simply incorporate the flame-retardant masterbatch into the plastic manufacturing process at the specified ratio to achieve plastic products with uniformly distributed antimicrobial properties.

Safety and Environmental Protection

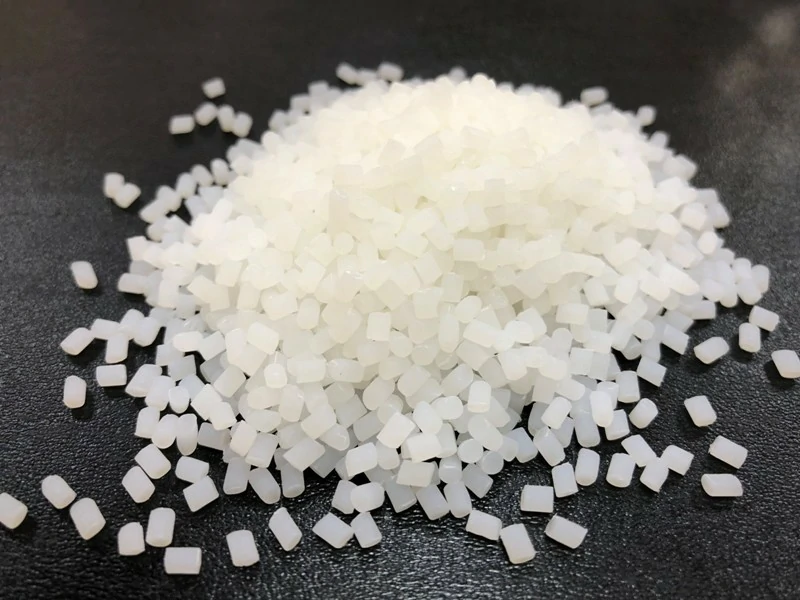

Utilises halogen-free or low-halogen flame retardant systems (compliant with RoHS and REACH regulations), minimising the release of toxic gases during combustion to meet environmental standards; being granular in form, it eliminates dust pollution.

Customisable production

Huashuo Masterbatch is an experienced masterbatch manufacturer offering bespoke sample development tailored to your requirements. Simply provide a sample or Pantone colour card.

Specifications

| Parameter | Typical Value |

|---|---|

| Flame Retardant Grade | V0 (1.6mm) / V1 (3.2mm) |

| Melting Point | 120-180℃ (depends on carrier) |

| Moisture Content | ≤0.5% |

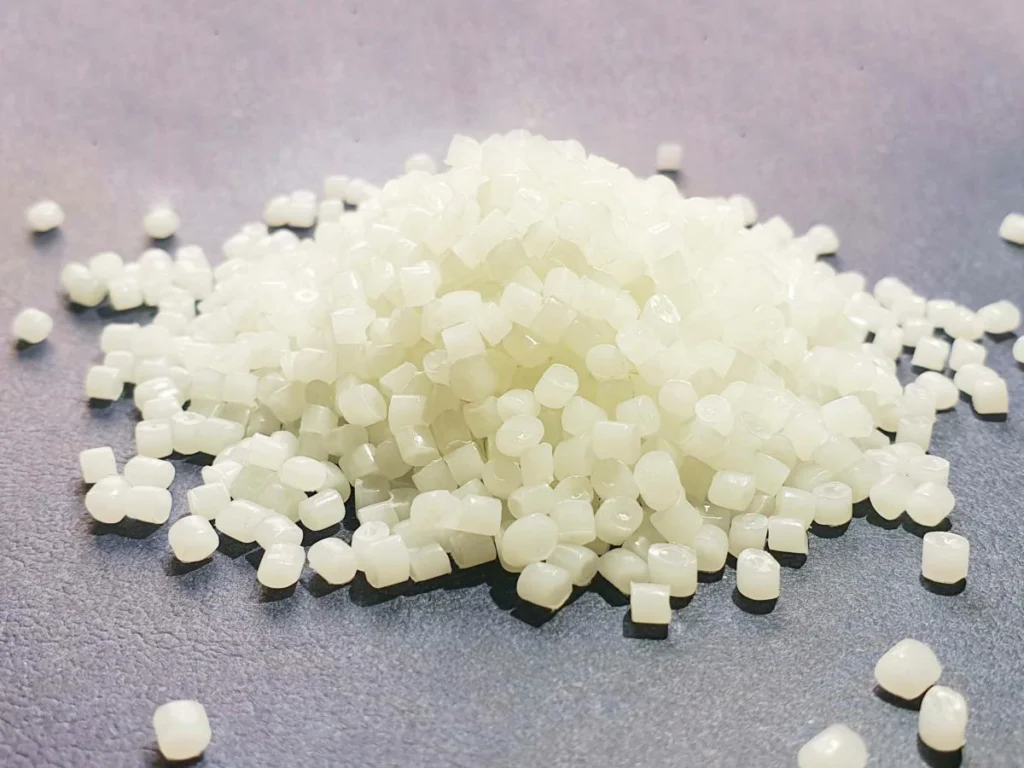

| Bulk Density | 0.5-0.8 g/cm³ |

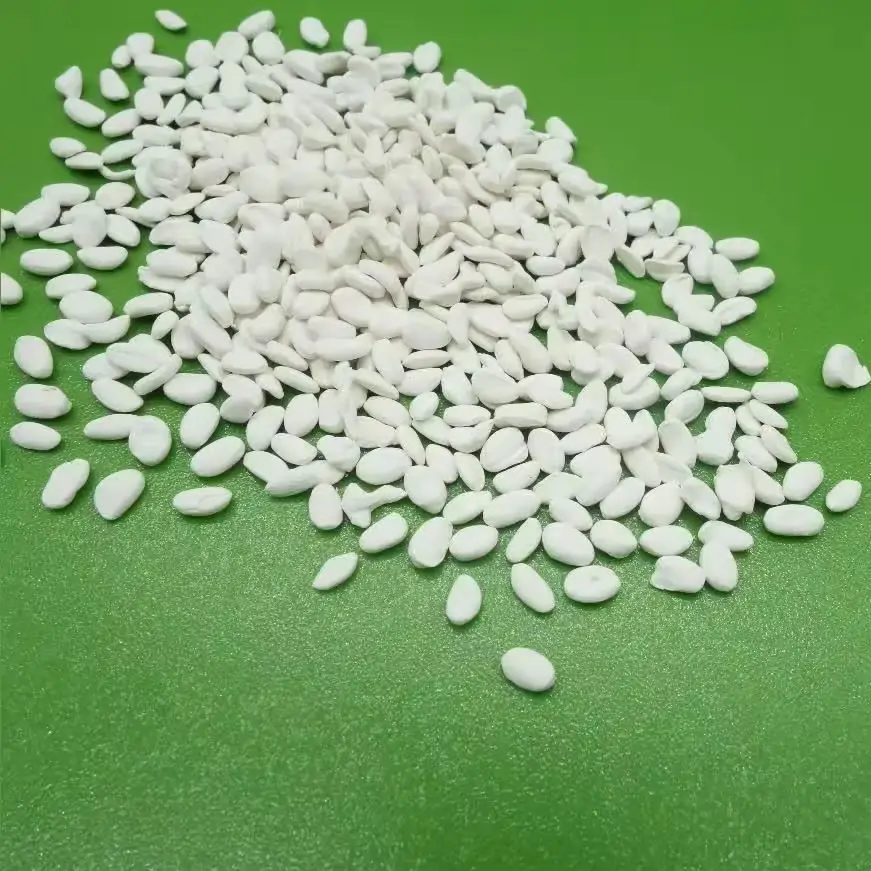

| Particle Size | 2-4 mm (cylindrical or spherical) |

| Thermal Decomposition Temperature | ≥280℃ |

Customized Flame Retardant Masterbatch

Huashuo can customize flame retardant masterbatchs according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, ABS, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

Flame Retardant Masterbatch Solutions

| Industry | Typical Application | Base Resin | Target Rating | Recommended Loading |

|---|---|---|---|---|

| Electronics | Socket Panel | ABS / PC-ABS | UL94 V-0 | 15% – 20% |

| Automotive | Battery Box | PP | UL94 V-0 | 20% – 25% |

| Wires & Cables | Insulation | LDPE / EVA | UL94 VW-1 | 25% – 35% |

| Appliances | Coffee Maker Housing | PP | UL94 V-2 / HB | 5% – 8% |

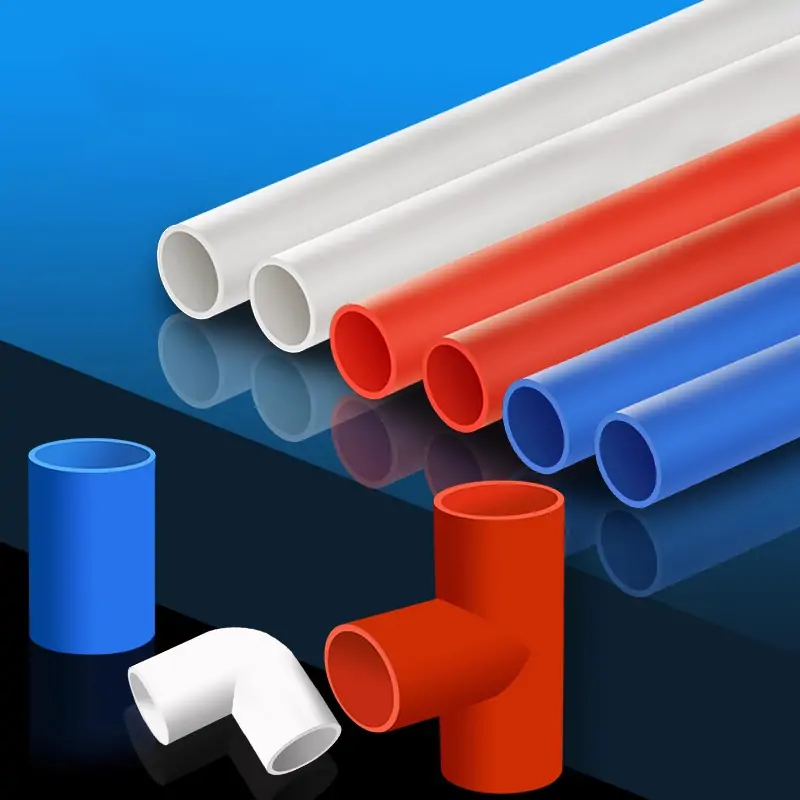

| Construction | Conduit Pipe | PVC | Self-extinguishing | 10% – 15% |

“Types of Flame Retardant Masterbatch ”

”

omprehensive Categories of Flame Retardant Masterbatch

Classified by Flame-retardant System

Halogen-Free Flame Retardant Masterbatch

Based on phosphorus, nitrogen, or inorganic flame retardants (such as magnesium hydroxide, aluminum hydroxide).

Halogen-Containing Flame Retardant Masterbatch

Contains bromine or chlorine-based flame retardants.

Intumescent Flame Retardant Masterbatch

Expands to form a carbon layer when heated, isolating heat and oxygen.

Classified by Carrier

PE Flame Retardant Masterbatch.

PP Flame Retardant Masterbatch.

PVC Flame Retardant Masterbatch.

ABS Flame Retardant Masterbatch, etc.

antioxidant Masterbatchs in Plastic

Flame-retardant Building pipes

Flame-retardant Building pipes Flame-retardant Conduit

Flame-retardant Conduit Flame-retardant Foam

Flame-retardant Foam

Flame-retardant Household Appliances

Flame-retardant Household Appliances Flame-retardant Packaging Bags

Flame-retardant Packaging Bags

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.