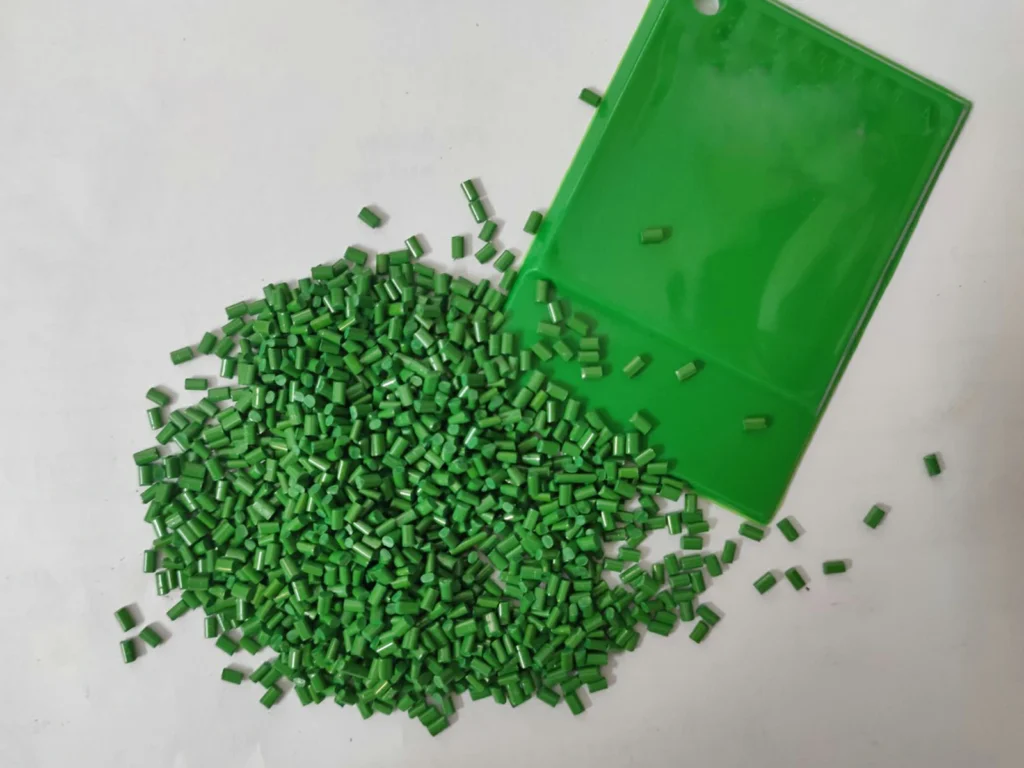

green Masterbatch

Green Masterbatch is a specialized coloring material formulated by blending green pigments, additives, and dispersants with polymer resin as the carrier through high-speed compounding and pelletization. It can be directly used for coloring plastic products, delivering stable, vibrant, and long-lasting green effects. Green color masterbatch offers excellent dispersion, compatibility, and weather resistance, making it widely applicable in packaging containers, appliance housings, building material profiles, and daily necessities.

- Color: Green

- Carrier Material: PE/PP/PS/ABS/PET/PC/HIPS

- Dispersants: Polyethylene wax, oleamide, stearamide

- Functional Additives: Lubricants, flame retardants, antistatic agents, anti-aging agents, clarity enhancers, anti-fog agents, antibacterial/antifungal agents, biodegradable additives

- Packaging: 25 KG/BAG

- Payment Terms: T/T, L/C

Advantages of Green Masterbatch

Vibrant Green Pigments with Superior Stability

Formulated with premium organic or inorganic green pigments, these offer high color saturation and strong coverage without fading, discoloration, or migration, enhancing product appeal.

Excellent Compatibility and Dispersibility

Compatible with various resin carriers such as PP, PE, ABS, etc. Incorporates dispersing agents to ensure uniform pigment distribution within the resin matrix, significantly reducing issues like color spots, streaks, and color variation.

Superior Weather and Light Resistance

Incorporates UV stabilizers and antioxidants to fortify resistance against sunlight, humid heat, acids, alkalis, and other environmental aggressors. Maintains vibrant color and prevents light fading even under prolonged outdoor exposure.

Convenient Processing

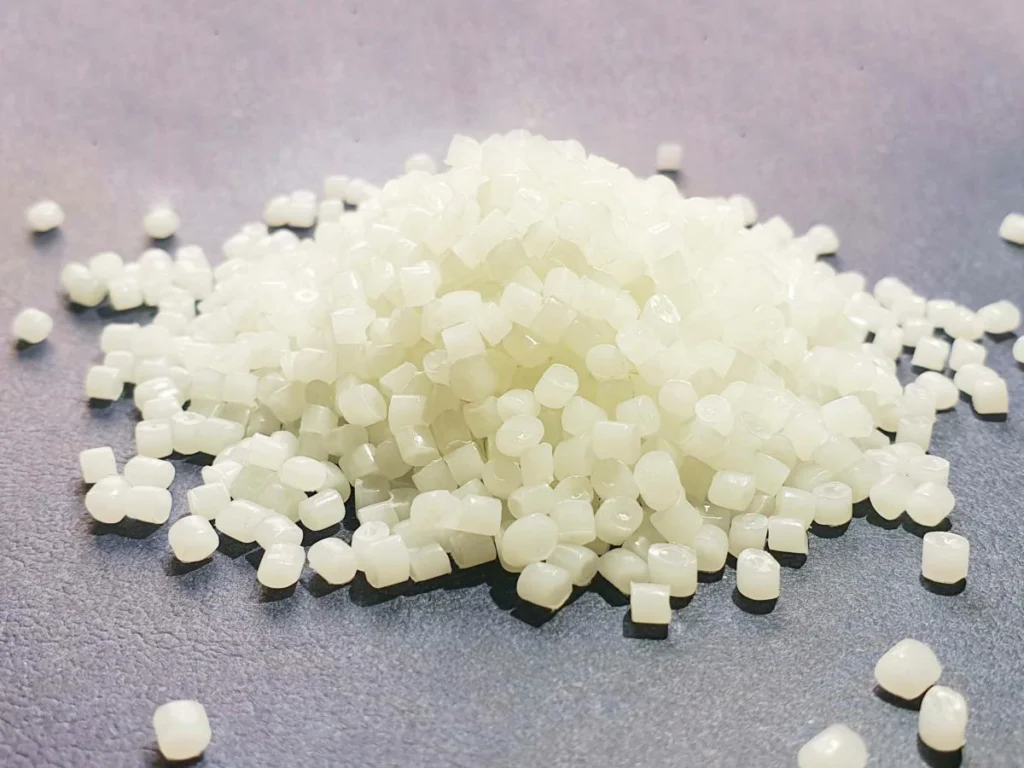

Green master batch comes in granular form, enabling precise metering, uniform mixing, and minimal dust generation. It can be directly fed into processing equipment, enhancing product strength and flowability while improving production stability and yield rates.

Suitable for multiple processing methods

Compatible with injection molding, extrusion, blow molding, film blowing, and other processing methods, maintaining stable performance under high-temperature and high-shear conditions.

48-Hour Custom Color Solution

High Customizability

We offer dedicated color matching services based on customer-provided color charts (e.g., Pantone) or samples, delivering precisely tailored formulations to ensure color accuracy.

Environmentally Friendly & Non-Polluting

Green colour masterbatch contains no heavy metals like lead, cadmium, mercury, or hexavalent chromium, nor halogens or phthalate plasticizers. It complies with international certifications such as RoHS and REACH, making it suitable for applications like food packaging and children’s toys.

Specifications

Green masterbatch is a specialized color masterbatch offering customization based on client’s application environment, material properties, and color requirements. Below are key parameters:

| Carrier | PE/PP/ABS/PS/PET/PA |

| Color | Green/Emerald Green/Fruit Green/Bluish Green/Customization |

| Light Resistance (Grade 1-8) | 8 |

| Heat Resistance (℃) | 1100 |

| Migration Resistance (Grade 1-5) | 5 |

| Grain Size | 2-3.5mm |

| Melting Point (℃) | 120~280 |

| Aberration | ≤0.5 |

| Moisture Content (%) | ≤0.02 |

| Specific Gravity | 1.6 |

Common Types of green Masterbatches

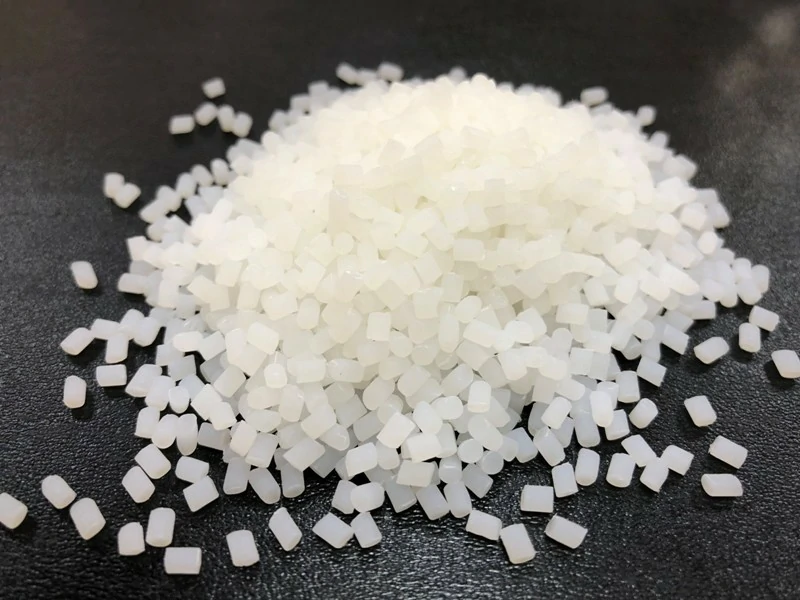

- General-purpose green color master batch: Suitable for common plastics like PE, PP, and HIPS, featuring bright colors and moderate cost. Widely used in daily-use plastics, packaging containers, and injection-molded parts.

- Food-grade green masterbatch: Manufactured with FDA-certified raw materials, meeting hygiene and safety standards. Ideal for food packaging bags, water bottles, tableware, and medical containers.

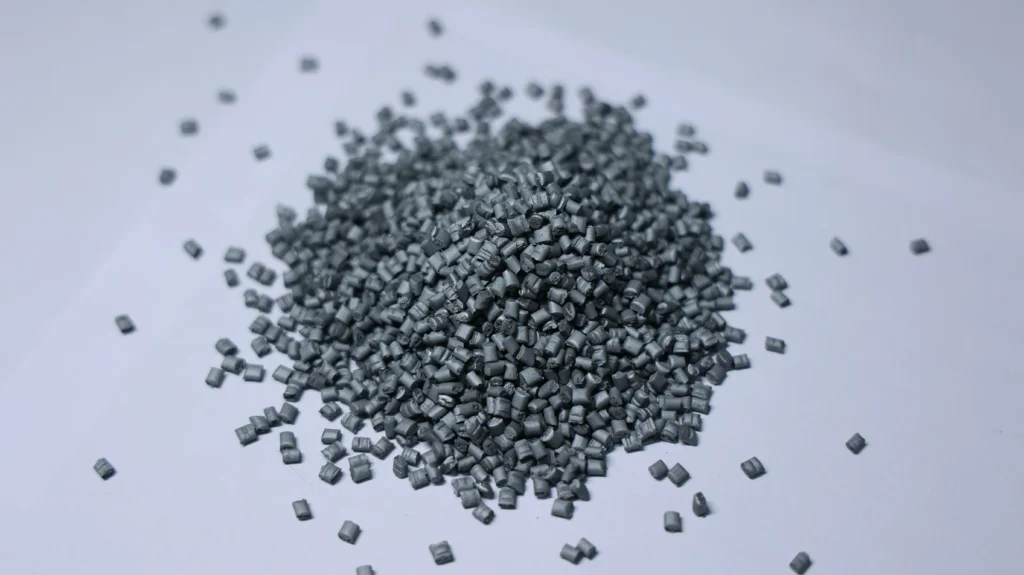

- Functional green master batch: Enhances multiple properties including antibacterial, antistatic, flame-retardant, and conductive capabilities to meet specialized requirements in high-end electronics, electrical, and engineering applications.

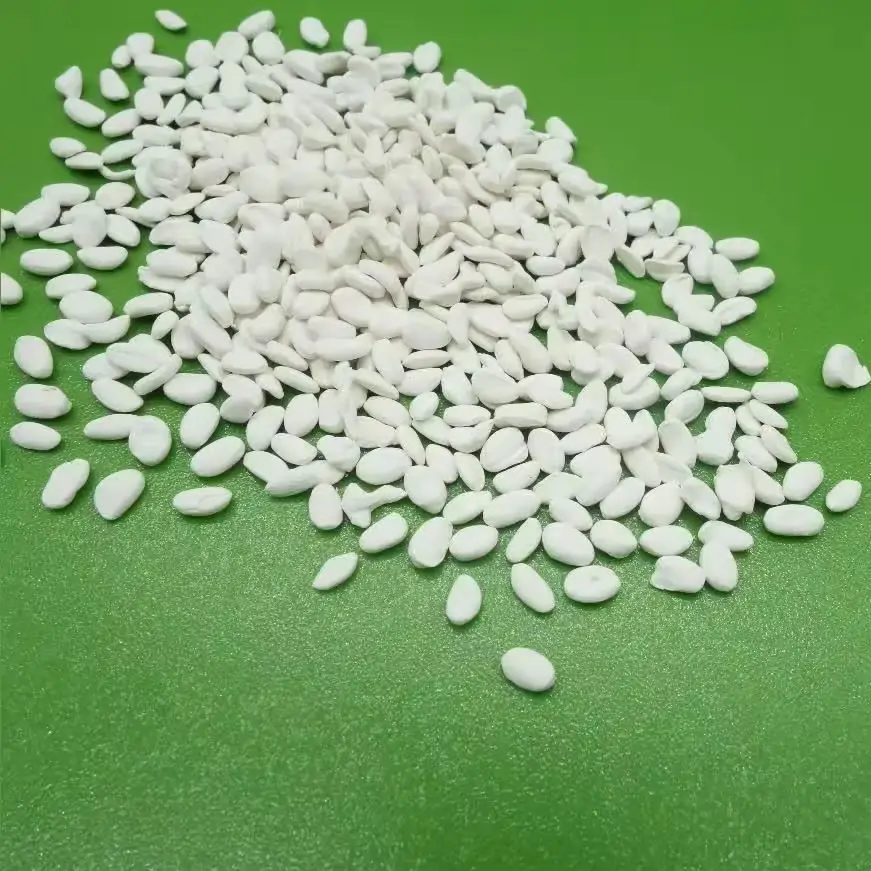

- Biodegradable green masterbatch: Utilizes bio-based carriers like PLA and PBAT to satisfy environmental degradation requirements. Suitable for biodegradable packaging bags and disposable products, aligning with global green and low-carbon trends.

“Green Masterbatch in Different Industries .”

.”

– used in film, extrusion, injection molding, foaming

Packaging Industry: Widely used in food packaging films, bottle caps, containers, and cosmetic packaging to enhance product visual recognition and brand image.

Home Appliances & Daily Goods: Features uniform green hues and a soft visual appeal, commonly applied in storage boxes, household items, ABS casings, and appliance panels, balancing functionality with decorative effects.

Electronics and Consumer Goods: Widely used in phone cases, charger housings, stationery, toys, and similar products, meeting consumer demands for both fashionable colors and eco-friendly safety.

Agriculture & Construction Materials: Excellent weather resistance and anti-aging properties enable widespread use in agricultural films, mulch films, pipes, shade nets, and plastic roofing tiles, maintaining color stability.

Automotive and Transportation: Suitable for plastic components like car trim, traffic barriers, and signage, providing visual identification while enhancing resistance to temperature and light exposure in complex environments.

Textile Fibers: Extensively used in producing colored fibers and fabrics, ensuring long-term colorfastness and fade resistance.

Optimizing productivity and costs

Green color masterbatches enhance the natural texture and visual comfort of plastic products, imparting fresh, elegant, and eco-friendly color effects. Widely applied in packaging materials, home appliances, construction materials, and agricultural plastic products. Achieves superior coloring performance through optimized pigment dispersion and carrier control.

consumer goods

consumer goods pvc-pipe

pvc-pipe traffic barriers

traffic barriers textile fibers

textile fibers

home appliances & daily goods

home appliances & daily goods automobile parts

automobile parts agricultural films

agricultural films

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.