Silver Masterbatch

Silver masterbatch is a high-concentration plastic coloring material composed of polymer resin as the carrier, blended with silver pigment, dispersants, lubricants, and various functional additives. Silver color masterbatch offers stability, heat resistance, and environmental friendliness, imparting a metallic silver luster and texture to products while maintaining uniform silver color and stable gloss. Widely used in home appliance housings, automotive trim, cosmetic packaging, and electronic casings.

- Color: Silver

- Carrier Materials: PP/PE/ABS/PET/PC/PA

- Dispersants: Polyethylene wax, oleamide, stearamide

- Functional Additives: Lubricants, flame retardants, antistatic agents, antioxidants, clarity enhancers, anti-fog agents, antibacterial agents, biodegradable additives

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmed

- Payment Terms: T/T, L/C

Advantages of Silver Masterbatch

Premium Metallic Finish

By controlling silver powder particle size, distribution, and concentration, silver color masterbatch delivers authentic, refined metallic reflections. This enhances product aesthetics, elevates visual sophistication, and strengthens brand image.

Superior Dispersibility

Utilizing modified resin carriers and advanced dispersion technology, silver particles distribute uniformly within the matrix, preventing agglomeration and color variation while improving product aesthetics and gloss retention.

Excellent Weather Resistance

Formulated with UV stabilizers and antioxidants, it offers strong UV resistance and anti-aging properties, enhancing color stability in prolonged outdoor or high-temperature environments.

High Processing Heat Resistance

Exceptional thermal stability enables processing temperatures up to 260°C, suitable for injection molding, extrusion, blow molding, and other manufacturing processes.

Environmental Safety

Free from harmful heavy metals like lead, cadmium, and mercury. Complies with international environmental certifications such as RoHS, ensuring safe application in food packaging and daily chemical products while supporting sustainable development.

48-Hour Custom Color Solution

Supports Customization

Flexibly adjust gloss levels and silver powder ratios according to customer requirements to precisely match product appearance and performance specifications, enhancing brand competitiveness and market adaptability.

Reduced Overall Costs

Directly adding silver masterbatches achieve a metallic appearance, eliminating the need for electroplating or painting processes. This saves labor and energy, prevents paint peeling and environmental pollution, and lowers manufacturing costs.

Specifications

Silver color masterbatch offers both visual appeal and multifunctional properties, combining aesthetics with practicality. Below are selected specifications:

| Carrier | PP/PE/PC/ABS/PET (Can be customized) |

| Color | Silver/Shiny silver/Matte silver (Customizable) |

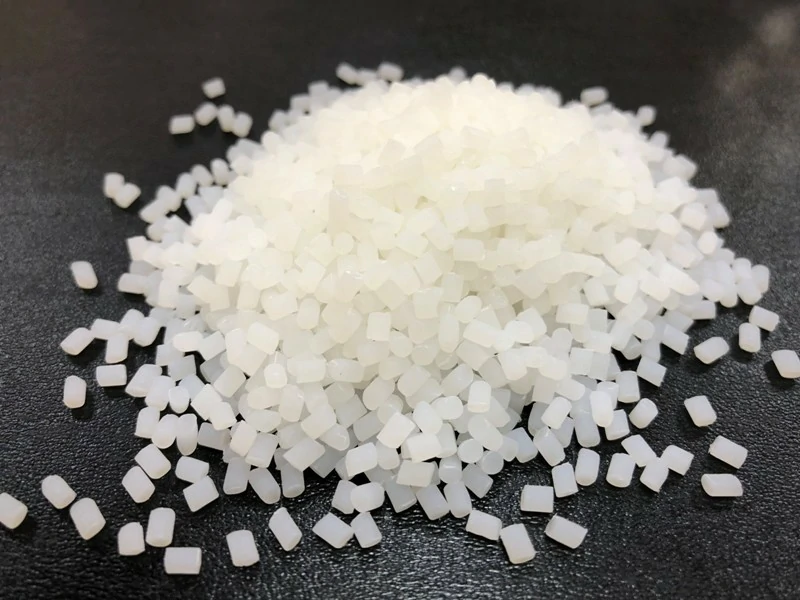

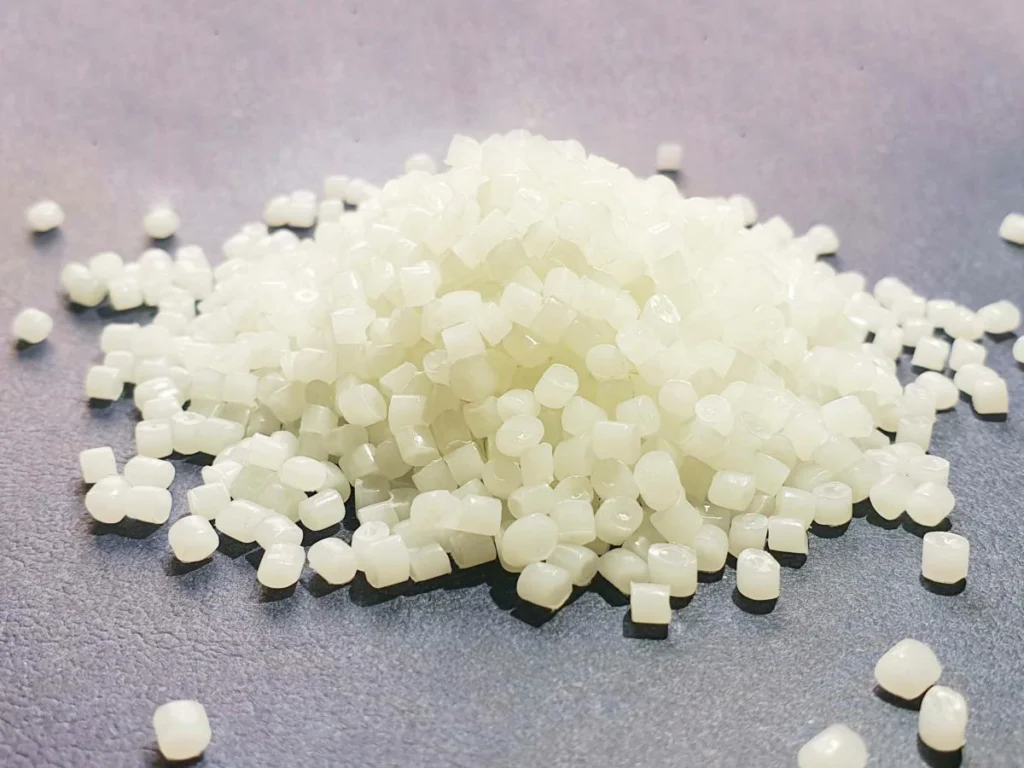

| Appearance | Silver-gray particles |

| Light Resistance (Grade 1-8) | 8 |

| Temperature Resistance (℃) | 160-350 |

| Migration Resistance (Grade 1-5) | 5 |

| Effective Solid Content (%) | 20.0±0.2 |

| Melting Point (℃) | 100-230 |

| Grain Size | 2-3.5mm |

| Moisture Content (%) | ≤0.02 |

| Eco-Friendly | ROHS compliant |

| Dispersion | High |

| Gloss Grades | High gloss |

Different silver masterbatch types meet diverse industry demands for visual texture, functional performance, and processing techniques, enhancing products’ visual appeal and application value.

Common Types of Silver Masterbatches

Based on visual effects, pigment systems, and application requirements, silver master batch are primarily categorized as follows:

- Bright Silver Color Masterbatch: Contains high-brightness silver powder with intense reflectivity, delivering a premium, sophisticated appearance. Commonly used for high-end appliance housings and electronic product casings.

- Matte Silver Masterbatch: Features a soft, non-reflective luster, suitable for electronic instrument housings, medical device casings, etc.

- Metallic Silver Masterbatch: Incorporates aluminum silver paste or coated silver powder for a pronounced metallic texture, serving as an alternative to spraying and electroplating.

- Silver-Gray Masterbatch: Features a neutral, subdued tone, commonly used for industrial components requiring wear resistance and aging resistance, as well as office supplies.

- Pearlescent Silver Masterbatch: Enhanced with pearlescent pigments for rich dimensional effects, suitable for cosmetic bottles, gift packaging, and high-end home decor items.

“Silver Masterbatch in Different Industries .”

.”

– used in film, extrusion, injection molding, foaming

Home Appliance Industry: Commonly used in TV bezels, air conditioner housings, fan blades, and other components to highlight an elegant, premium metallic finish, elevate brand image, and meet aesthetic design requirements for home appliances.

Automotive Industry: Widely applied in interior and exterior trim parts such as center console panels, decorative moldings, emblem bases, and switch housings to enhance heat resistance and weatherability, ensuring long-term use without fading or peeling.

Cosmetics & Packaging Industry: Extensively applied in bottle caps, containers, toothpaste tubes, and premium gift packaging. Delivers high-coverage, high-brightness silver finishes that elevate product sophistication and brand recognition.

Building Materials Industry: Frequently used in PVC decorative panels, door/window profiles, and home accessories to enhance UV resistance and oxidation resistance, making them suitable for outdoor environments.

Daily Goods & Stationery: Environmentally friendly and non-toxic with high safety standards. Commonly used in plastic stationery, toys, and decorative items to achieve uniform, stable metallic luster, enhancing visual appeal and brand value.

Electronics & Digital Products: Replaces spray painting with silver color masterbatch to prevent paint chipping, extend product lifespan, and simplify manufacturing. Commonly used in phone cases, laptop shells, audio panel covers, and similar components.

Optimizing productivity and costs

Silver colour masterbatch imparts a refined, elegant metallic texture and high-gloss appearance to plastic products, widely applied in appliance housings, automotive components, and premium packaging. By improving pigment dispersion and flow properties, it enhances surface uniformity and processing efficiency while reducing spraying costs, energy consumption, and overall expenses.

Automotive Interior

Automotive Interior Corrosion-Resistance Pipe

Corrosion-Resistance Pipe Cosmetics & Packagin

Cosmetics & Packagin

Home Appliance

Home Appliance Daily Goods

Daily Goods

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.