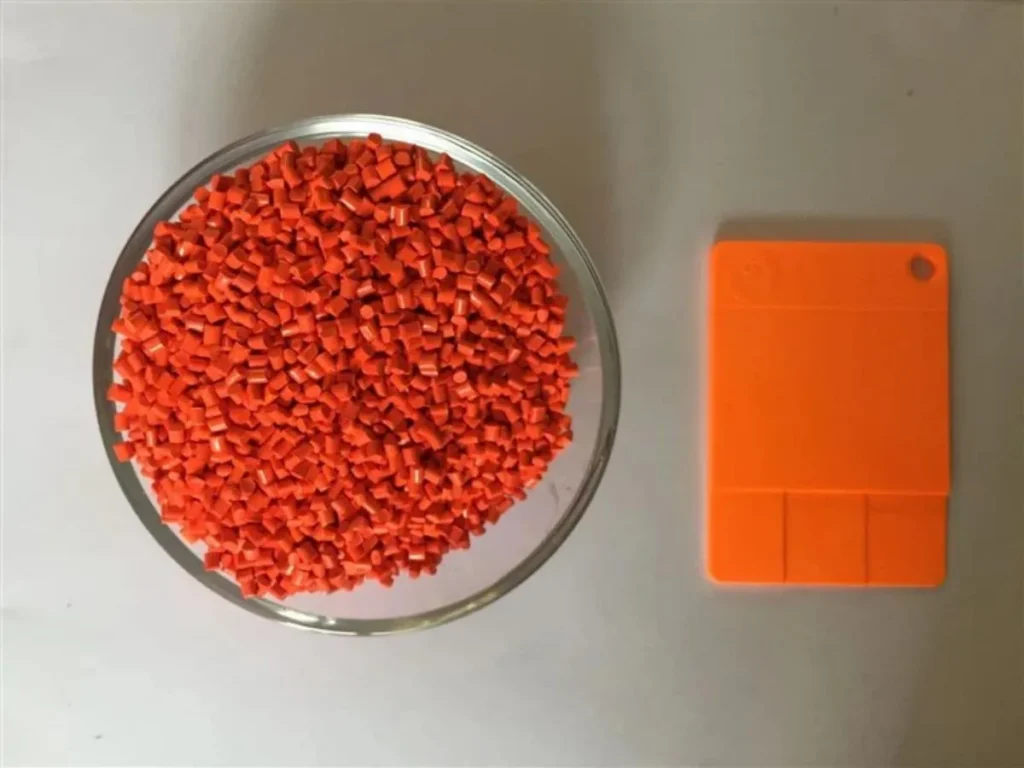

Orange Masterbatch

Orange color masterbatch is a specialized color masterbatch formulated as a high-concentration coloring material. It uses polymer resin as a carrier and incorporates orange pigments, additives, and dispersants. It can be directly mixed with plastic raw materials to impart a uniform, stable, and vibrant orange hue to finished products. Offering high color concentration stability, superior weather resistance, and eco-friendly properties, orange masterbatch is widely used in plastic packaging, appliance housings, building material profiles, and other applications.

- Color: Orange

- Carrier Materials: PE/PP/PVC/ABS/PET/PS

- Dispersants: Polyethylene wax, stearic acid, zinc stearate

- Functional Additives: Lubricants, antioxidants, flame retardants, antistatic agents, anti-fog agents, antibacterial agents, stabilizers

- Packaging: 25kg/bag

- Leadtime: 7 days after order confirmed

- Payment Terms: T/T, L/C

Advantages of Orange Masterbatch

Enhanced Visual Appeal

Utilizing high-concentration, high-performance orange pigments, the product delivers rich, brilliant hues that resist fading over extended use, effectively enhancing the visual appeal of plastic goods.

Excellent Dispersibility

The compounding process of orange colour masterbatch ensures uniform pigment particle distribution, preventing streaks, color variations, or black spots while improving surface smoothness and aesthetic quality.

High Processing Heat Resistance

Withstands processing temperatures ranging from 120°C to 300°C, suitable for diverse thermoplastic resin systems and various manufacturing processes.

Superior Weather Resistance

Enhanced UV and oxidation resistance maintains long-term color vibrancy and stability, ideal for outdoor applications or products exposed to prolonged sunlight.

48-Hour Custom Color Solution

Environmentally Friendly & Safe

Complies with ROHS, REACH, and other environmental standards. Free from heavy metals and toxins, suitable for high-safety applications like food packaging and children’s toys.

Easy Handling & Dust-Free Operation

Granular form facilitates precise measurement and transportation. Directly mixes with plastic raw materials, reducing dust pollution and improving workshop conditions.

Specifications

Orange masterbatch is a specialized compound favored by plastic manufacturers for its multiple advantages. Below are the parameters for orange color masterbatch:

| Carrier | PP/PE/ABS/PET/PVC |

| Color | Orange (customizable) |

| Light Resistance (Grade 1-8) | 8 |

| Temperature Resistance (℃) | 160ºC-300ºC |

| Migration Resistance (Grade 1-5) | 5 |

| Effective Solid Content (%) | 20.0±0.2 |

| Melting Point (℃) | 130-330 |

| Grain Size | 2-3.5mm |

| Moisture Content (%) | ≤0.02 |

| Eco-Friendly | ROHS Compliant |

| Dispersion | High |

Orange Masterbatch Processing Applications

Orange master batch is widely used in various plastic molding processes, offering excellent compatibility and color performance:

- Injection Molding: Masterbatch disperses uniformly, resulting in high gloss and visually appealing surfaces. Commonly used for plastic casings, toys, stationery, automotive interiors, and similar products.

- Blow Film: Exhibits excellent flow and light transmission, suitable for plastic films, packaging bags, food pouches, etc. Films feature vivid colors without color spots.

- Extrusion: Possesses outstanding thermal stability with stable color during extrusion. Commonly used in pipes, sheets, cable jackets, and other products to enhance weather resistance.

- Blow Molding: Commonly used for beverage bottles, cosmetic containers, lubricant bottles, and other packaging vessels, enhancing product transparency and visual appeal.

“Orange Masterbatch in Different Industries .”

.”

– used in film, extrusion, injection molding, foaming

Home Appliances & Daily Goods: Features rich color saturation and high brightness, frequently applied to appliance casings, kitchenware, and daily plastic products, lending products a more fashionable and vibrant appearance.

Packaging Industry: Commonly used in packaging bottles and containers for food, daily chemicals, pharmaceuticals, etc., enhancing visual appeal and brand recognition.

Agriculture and Horticulture: Commonly used in agricultural films, water pipes, flower pots, and other plastic products to improve light resistance and anti-aging properties, ensuring suitability for long-term outdoor use.

Building Materials & Piping: Frequently used in plastic sheets, pipe fittings, decorative profiles, and lamp housings to enhance weather resistance, anti-aging properties and long-term color stability.

Textiles & Cables: Commonly applied in polyester fibers, cable sheaths, engineering plastics, and other high-performance materials for abrasion resistance and colorfastness.

Cultural Creativity and Toys: Featuring bright, warm hues, it is frequently used for coloring injection-molded products like stationery, gifts, and toys, enhancing product appeal and market attractiveness.

Optimizing productivity and costs

Orange masterbatch imparts vibrant, warm hues to plastic products, enhancing their vitality and appeal. Widely used in packaging, home appliances, stationery, and other fields, it ensures uniform dispersion and excellent compatibility. This results in rich, stable colors with reduced color variation and defects. Superior coverage and processing properties minimize material waste, boost production efficiency, and lower costs.

Plastic Packaging

Plastic Packaging Home Appliances

Home Appliances Flower Pots

Flower Pots

Plastic Sheets

Plastic Sheets Plastic Film

Plastic Film

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.