Anti UV Masterbatch

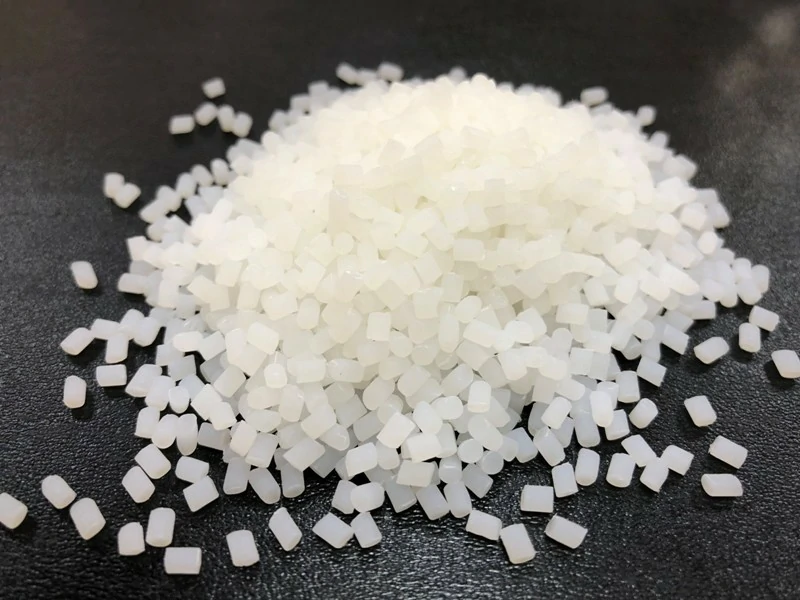

Anti UV masterbatch is a functional modified masterbatch specifically designed to prevent plastic products from aging, fading, and cracking under ultraviolet radiation. It is formulated using polymer resin as a carrier, blended with UV absorbers and HALS. Anti UV masterbatch effectively absorbs ultraviolet radiation and inhibits free radical reactions, safeguarding the structural integrity of polymer molecular chains. This extends the service life of products and enhances the durability of their appearance and color.

- Colour: Black, red, silver, transparent, and other standard hues. Custom formulations available based on Pantone color charts or submitted samples.

- Suitable Substrates: PE, PP, PET, ABS, PC, PA

- Dispersants: Polyethylene wax, stearate, ethylene bis stearamide (EBS)

- Suitable Plastic Processing Methods: Injection molding, extrusion molding, blow molding, film blowing

- Package: 25KG/BAG

- Leadtime:7 days after order confirmation.

- Payment Terms: T/T, L/C

aDVANTAGES

Choose Anti UV masterbatch for long-term protection and enhanced plastic durability.

Exceptional UV resistance

Utilizes high-efficiency UV absorbers and a photostabilization system to block ultraviolet radiation, improving structural stability in outdoor environments.

Long-lasting appearance and performance

Retains transparency, gloss, and strength over extended use, meeting both aesthetic and durability requirements.

Superior Weather Resistance

Maintains superior performance under high temperatures, humidity, and intense sunlight without yellowing, cracking, or chalking. Suitable for agricultural and construction applications.

Excellent Processing Compatibility

Compatible with multiple polymers, ensuring stable performance during injection molding, blow molding, extrusion, and film blowing processes without migration or discoloration.

Broad Substrate Compatibility

Compatible with multiple resin systems including PE, PP, and PC, enabling flexible application across various plastic products to enhance compatibility and protective efficacy.

Cost-effective

UV masterbatch offers convenient addition, eliminating traditional addititional processes. It delivers long-lasting protection at low cost, boosting market competitiveness.

Specifications

UV-resistant masterbatch formulations come in various types. Below are some of their parameters:

| Product name | Anti UV masterbatch |

|---|---|

| UV Protection Range | 280–400nm |

| Absorber Content | 1% – 5% (Adjustable) |

| Melt Flow Index | 5–15 g/10 min |

| Density | 0.92-1.25 g/cm³ |

| Recommended Addition Rate | 1-3% |

| Compatibility | Excellent |

| Heat Resistance | Stable at 280°C for short-term processing |

| Storage Conditions | Store in a cool and dry place |

Customized Anti UV Masterbatch

Huashuo can customize Anti-UV color masterbatches according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, PET, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

Applications of Anti UV Color Masterbatches

| Industry | Carrier Resin | Loading (%) | Application Fields |

|---|---|---|---|

| Agriculture | PE / EVA | 1.0% – 2.5% | Greenhouse films, mulch films, anti-aging films |

| Packaging | PE / PP / PET | 1.0% – 2.0% | Food packaging, beverage bottles, cosmetic packaging |

| Construction | PVC / PP | 1.5% – 3.0% | Exterior wall panels, roofing panels, decorative components |

| Automotive | ABS / PC | 1.0% – 2.5% | Dashboards, rearview mirror housings, headlight covers |

| Outdoor Home & Leisure Products | PE / PP | 1.0% – 2.0% | Garden furniture, storage boxes, children’s toys |

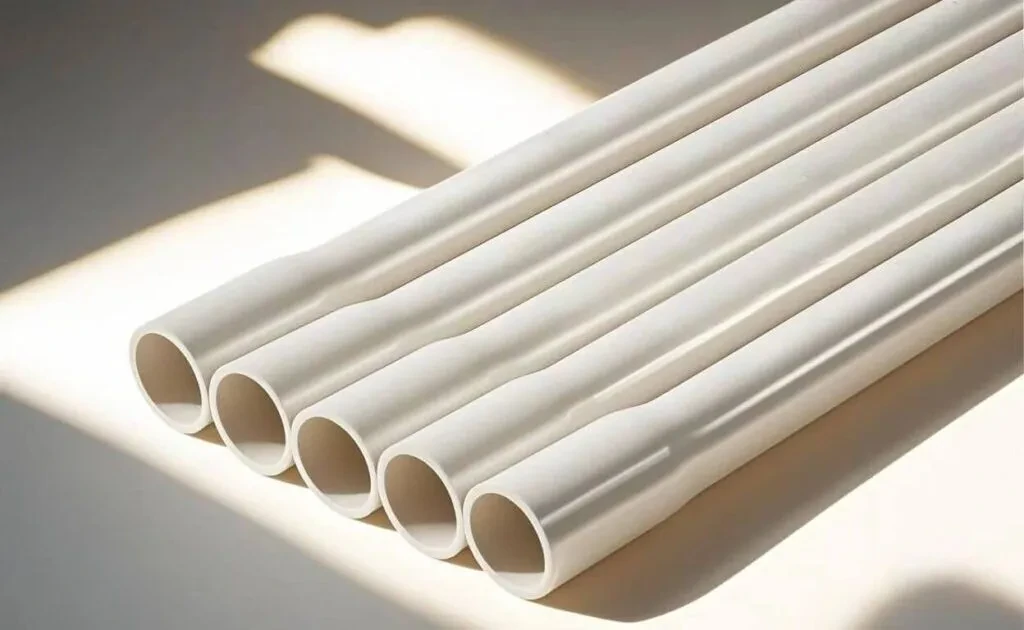

| Cable & Pipeline Systems | PE / PA | 1.0% – 3.0% | Communication conduits, cable jackets, water supply pipelines |

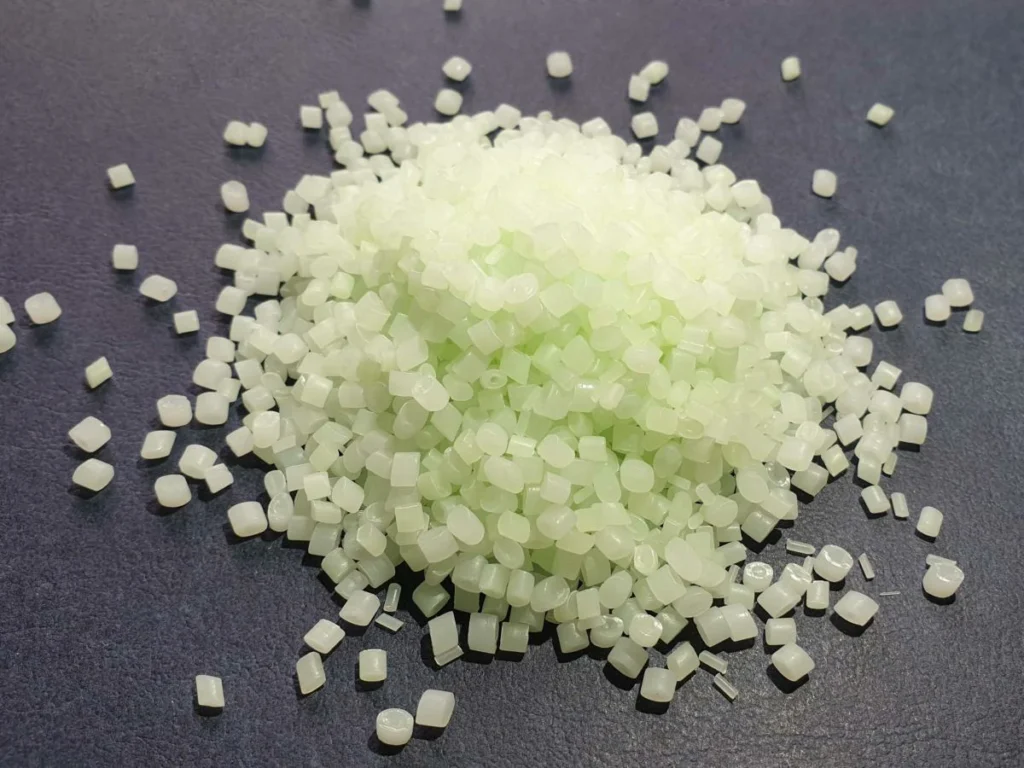

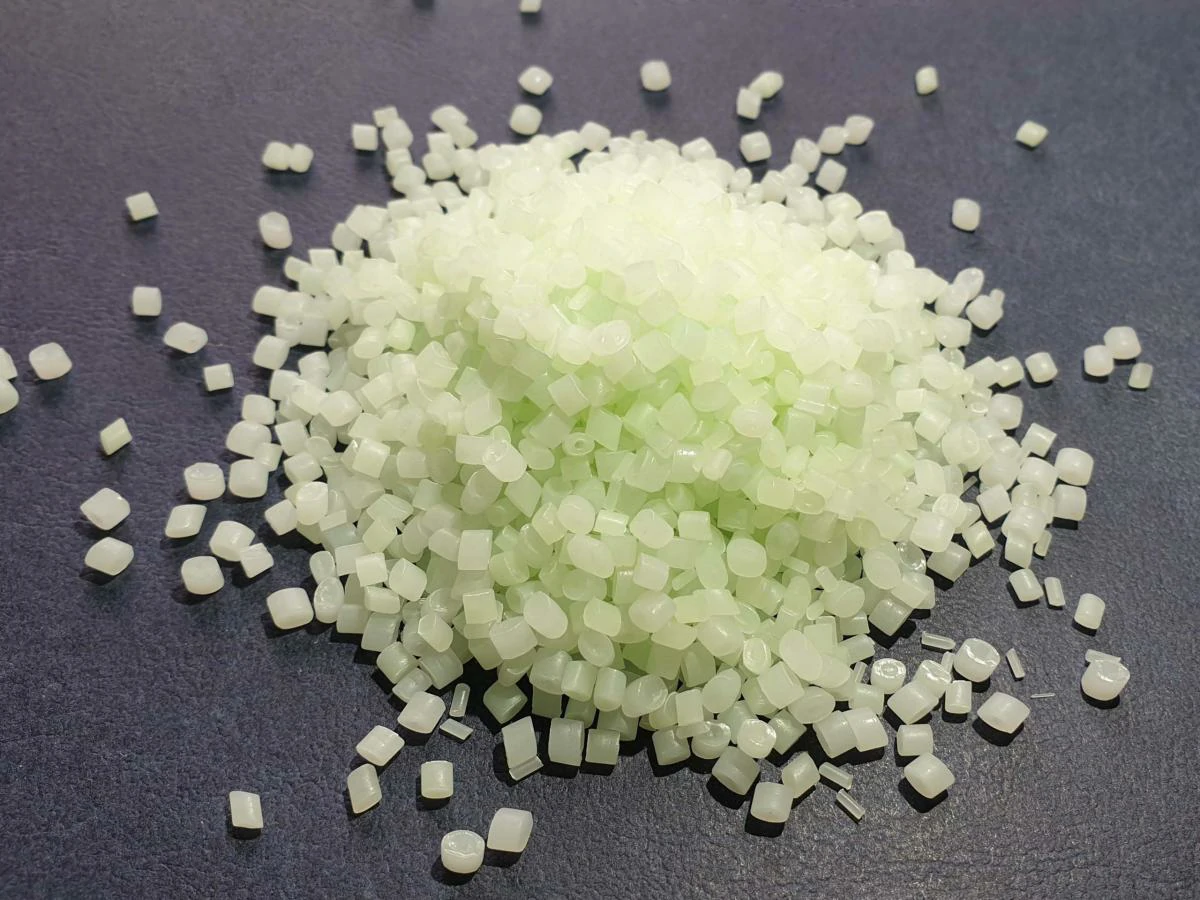

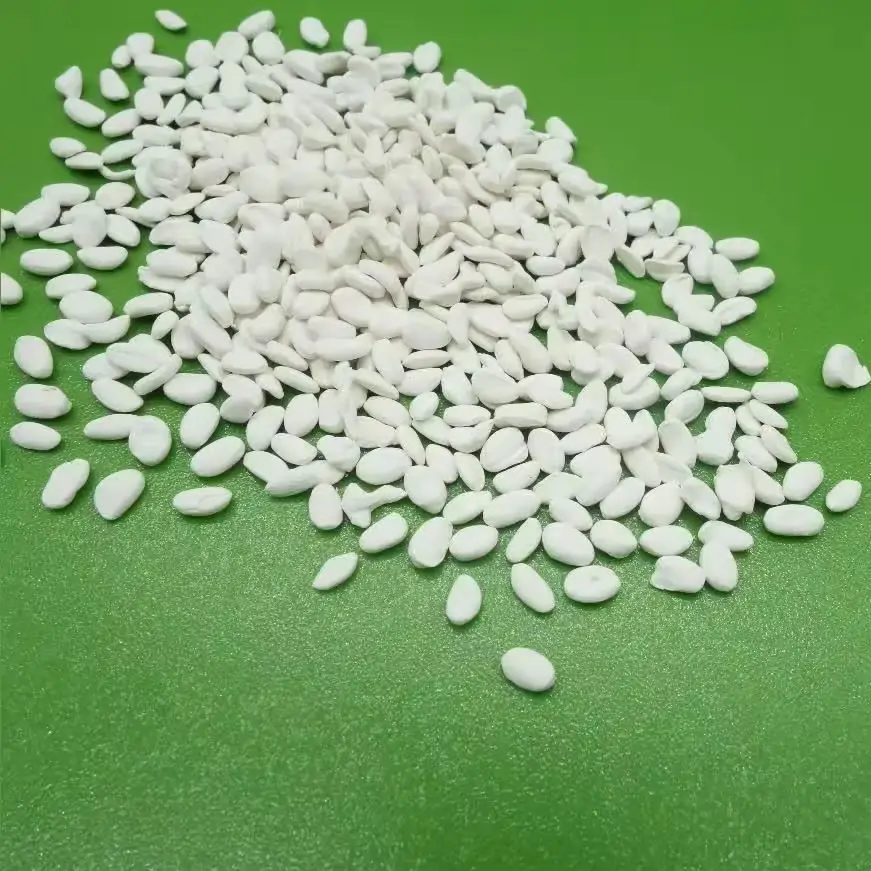

“Types of Anti UV Masterbatch ”

”

Multifarious anti-UV masterbatch types to tackle outdoor ageing and fading

General Purpose Anti UV Masterbatch: Suitable for various general-purpose plastic products such as PE, PP, ABS, etc. Provides fundamental UV protection and anti-aging properties. Cost-effective with stable protective performance.

Transparent Anti-UV Masterbatch: Employs colorless or light-colored UV absorbers to balance high light transmittance with UV resistance. Suitable for transparent films, containers, display panels, etc., enhancing color stability and appearance.

High-Temperature Resistant Anti-UV Colour Masterbatch: Suitable for high-temperature engineering plastics like PA, PC, PET, PBT, etc., offering excellent thermal stability and anti-degradation properties. Primarily used in products exposed to high temperatures, such as electrical enclosures and industrial machinery components.

Colored Anti-UV Color Masterbatch: Combines UV protection with high-quality coloring to optimize both color expression and weather resistance. Suitable for products requiring vivid appearance and long-term outdoor exposure.

High Weather-Resistant Anti UV Masterbatch: Utilizes a composite UV absorber system for use in high-intensity sunlight areas, preventing discoloration and chalking of products. Commonly used in outdoor advertising boards, agricultural films, building materials, etc.

Multi-Functional Anti UV Master batch: Integrates multiple functions including UV resistance, oxidation resistance, and flame retardancy. Meets the demands of high-end industrial and specialized applications, extending product lifespan while enhancing safety and stability.

anti-UV Masterbatchs in Plastic

UV-exposure communication conduits

UV-exposure communication conduits cosmetic packaging bottle

cosmetic packaging bottle food packaging films

food packaging films

mulch films

mulch films exterior wall panels

exterior wall panels

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.