Antistatic Masterbatch

Antistatic masterbatch is a functional modified masterbatch specifically designed to reduce static electricity buildup on plastic product surfaces. By incorporating anti-static agents, it enables rapid dissipation of surface charges, preventing issues such as dust adhesion, electrostatic discharge, and damage to electronic components. Antistatic color masterbatch enhances the surface conductivity of plastic products, achieving surface resistivity that meets anti-static standards. It is widely used in electronic packaging, automotive interiors, home appliance housings, optical films, and other fields.

- Colors: Pale yellow, natural color, translucent, and other standard colors. We can customize colors based on customer samples or Pantone color charts.

- Suitable Base Materials: PE, PP, PET, ABS, etc. Custom substrates supported.

- Dispersants: Polyethylene wax, oxidized polyethylene wax, stearate, etc.

- Applicable Plastic Processing Methods: Injection molding, extrusion molding, blow molding, cast film, etc.

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmation.

- Payment Terms: T/T, L/C

aDVANTAGES

Select anti-static masterbatch to eliminate surface charges on plastics, enhancing both safety and aesthetics.

High-Efficiency Antistatic Performance

Through migratory or permanent anti static systems, it effectively reduces surface resistivity of products, enabling rapid dissipation of static electricity to prevent dust adhesion and electrostatic discharge.

Enhanced Attractiveness

Prevents dust and particle adhesion on plastic surfaces, maintaining cleanliness and luster while extending display life and overall durability.

Excellent Process Adaptability

Compatible with various substrates including PE, PP, ABS, and PET, suitable for multiple processes such as injection molding, extrusion, film blowing, and cast film production.

Stable and Long-Lasting Antistatic Effect

Utilizing polymeric polyether or conductive filler systems, it forms a uniform conductive layer on product surfaces, maintaining stable anti-static performance in both dry and humid environments.

Enhanced Safety

Effectively reduce the risk of sparks and explosions caused by electrostatic discharge during production and use, ensuring the safety of personnel and equipment.

Environmentally Friendly and Cost-Effective

Complies with international standards like RoHS and REACH, contains no harmful components, requires low addition ratios, reduces costs, and enhances market competitiveness.

Specifications

Anti static masterbatches can be customized for different plastic systems and application requirements. Key parameters are as follows:

| Product name | Antistatic Masterbatch |

|---|---|

| Base Polymer | PET/PS/PA/TPU (Can be customized) |

| INCHR Grade | P109AN/120T |

| Anti-static Mechanism | Migratory / Permanent (optional) |

| Surface Resistance | 1.9×10E7 Ohms |

| Melt Flow Index (MFI) | 5 – 15 g/10min |

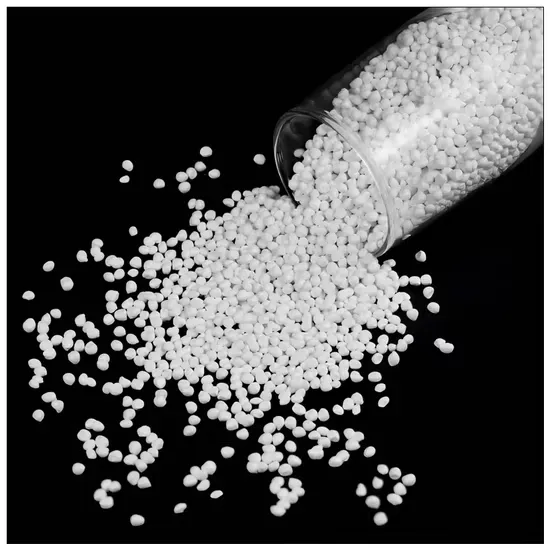

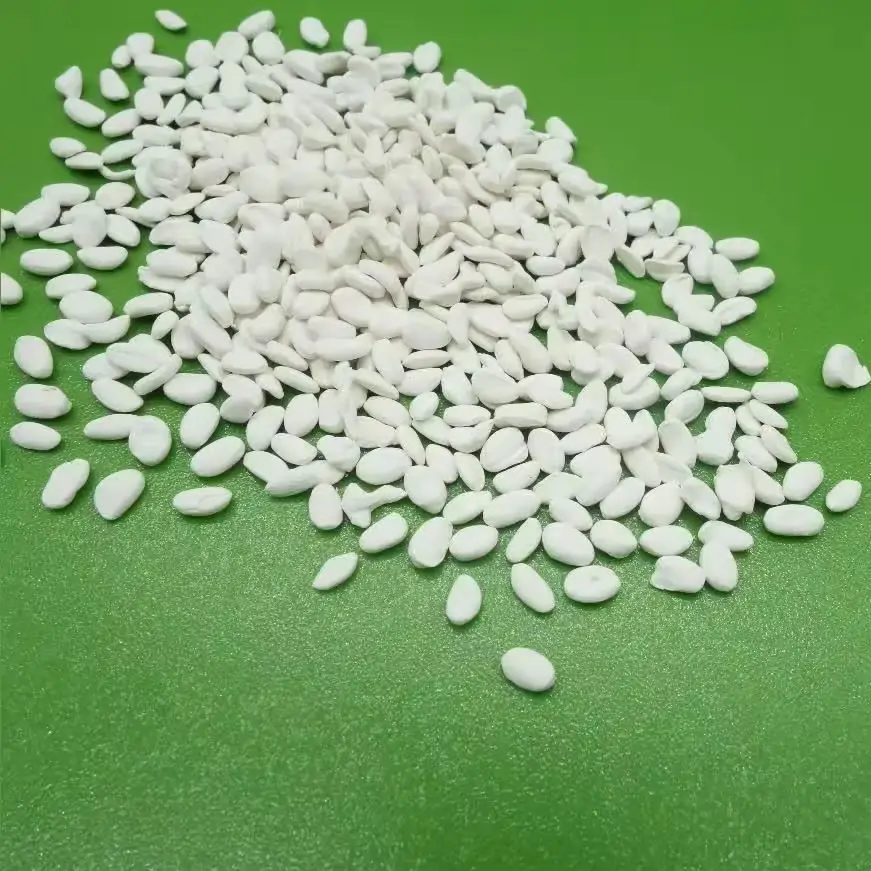

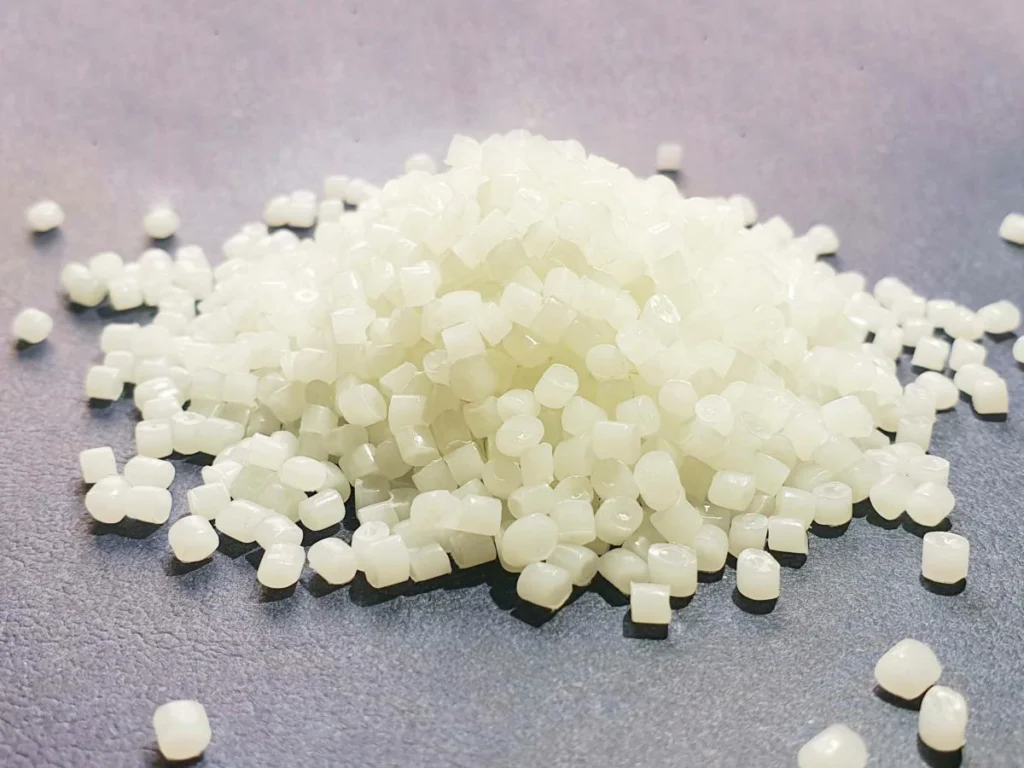

| Appearance | Granules |

| Color | Light or Translucent |

| Processing Temperature Range | 160°C – 280°C |

| Recommended Dosage | 10-18 wt% |

| Processing | Blowing/Casting/Injection/Extrusion |

Customized Antistatic Masterbatches

Huashuo can customize antistatic colour masterbatches according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, PET, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

Applications of Antistatic Masterbatches

Antistatic color masterbatch finds extensive applications across electronics, automotive, packaging, medical, and other industrial sectors. Key application examples include:

| Industry | Carrier Resin | Loading (%) | Application Fields |

|---|---|---|---|

| Electronics & Electrical | ABS / PS / PC | 1.5% – 2.5% | Anti-static packaging boxes, electronic component housings, explosion-proof instrument covers |

| Packaging & Film Industry | PE / PP / PET | 1% – 2% | Antistatic packaging film, dust-proof bags, food packaging containers |

| Automotive Manufacturing | PP / PC / PA | 1.5% – 3% | Dashboards, interior trim components, electronic wiring harness parts |

| Medical and Hygiene Products | PE / PET | 1% – 2% | Medical packaging bags, surgical instrument housings, dust covers |

| Fiber and Nonwoven Industry | PP / PA | 1% – 2% | Antistatic fibers, protective clothing fabrics, antistatic filter cloth |

“Types of Antistatic Masterbatch ”

”

Multiple types of anti static masterbatch prevent static buildup, maintain surface cleanliness, and enhance overall appearance and operational safety.

Migratory Antistatic Masterbatch: Utilizes anti-static masterbatch with migratory properties to form a conductive layer after product molding, facilitating charge dissipation. Offers noticeable initial effects at a lower cost, suitable for short-term applications or packaging products such as plastic bags and films.

Permanent Antistatic Masterbatch: Constructs a permanent conductive network through polyether or conductive polymer systems, delivering enduring and stable anti-static performance. Maintains long-term antis-tatic performance even in low-humidity environments, commonly used in electronic device housings, automotive components, industrial products, etc.

Conductive Antistatic Masterbatch: Utilizes conductive fillers like carbon black, carbon nanotubes, or conductive carbon fibers to reduce the volume resistivity of products. Combines anti-static and conductive functions, suitable for explosion-proof zones, electronic protective packaging, and industrial safety components.

Transparent Antistatic color Masterbatch: Utilizes colorless anti-static agents to preserve the optical properties of transparent products while providing anti-static protection. Suitable for transparent packaging films, optical films, and transparent covers, offering excellent visual aesthetics.

antistatic Masterbatches in Plastic

antistatic electronic component housings

antistatic electronic component housings antistatic-film

antistatic-film antistatic fibers

antistatic fibers

medical packaging bags

medical packaging bags automotive interior trim components

automotive interior trim components

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.