Antifog Masterbatch

Antifog masterbatch is a functional masterbatch specifically designed for plastic films and transparent products. By altering the surface tension of materials, it prevents water vapor from condensing into fog droplets, maintaining high transparency and visual clarity in finished goods. Anti-fog masterbatch is widely used in food packaging, agricultural greenhouse films, and transparent containers.

- Colors: Transparent, translucent, white, light blue, etc.

- Suitable Base Materials: PE (LDPE, LLDPE), PP, PET, etc.

- Dispersants: Polyolefin wax, EVA, nonionic surfactants

- Applicable Plastic Processing Methods: Blow molding, extrusion, injection molding, etc.

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmation.

- Payment Terms: T/T, L/C

aDVANTAGES

Choose antifog masterbatches for maintain high transparency and visual clarity

Superior Anti-Fog Performance

By reducing surface tension, water vapor spreads uniformly into a transparent film rather than forming droplets, effectively preventing condensation obstruction and maintaining clarity.

High Transparency and Gloss

Avoiding blurring caused by fog condensation, guarantee packaging or agricultural films retain high light transmission and visual cleanliness, enhancing product display appeal and aesthetics.

Safety and Environmental Compliance

Utilizes food-grade anti-fog additives and non-toxic dispersion systems, certified under ROHS, FDA, and other international standards, meeting requirements for food packaging and eco-friendly materials.

Adaptable to multiple processes

Suitable for various forming processes such as film blowing, casting, extrusion, and injection molding. Exhibits good thermal stability without delamination or migration.

Excellent processing compatibility

Compatible with various resin carriers including PE, PP, and PET. Does not affect plastic melt flow or mechanical properties, improving smooth and stable processing.

High Cost-Effectiveness

Effectively prevents product spoilage and frequent cleaning caused by condensation, extending product lifespan and reducing maintenance costs.

Specifications

| Product name | Antifog Masterbatch |

|---|---|

| Carrier Resin | PE / PP / EVA (can be customized) |

| Anti fog Type | Migratory / Permanent / Composite |

| Anti-fog Component Content | 5% – 20% (Custom) |

| Melt Flow Index | 5 – 25 g/10min |

| Processing Temperature Range | 130°C – 260°C |

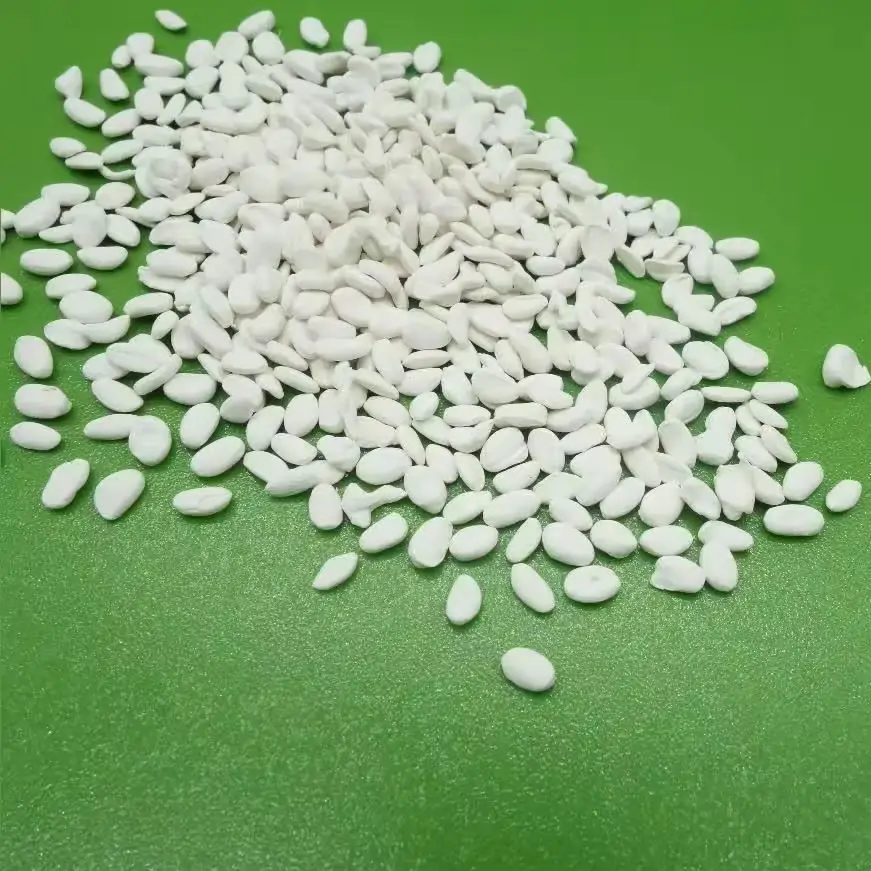

| Appearance | Granules |

| Color | Transparent or Light(As request) |

| Recommended Addition Ratio | 2% – 6%(AS request) |

| Processing | Blowing/Casting/Injection/Extrusion |

Customized Antifog Masterbatches

Huashuo can customize antifog color masterbatches according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, PET, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

Applications of Antifog Masterbatches

Anti fog masterbatch finds extensive use across packaging, agriculture, healthcare, and other industrial sectors. Key application examples include:

| Industry | Carrier Resin | Loading (%) | function |

|---|---|---|---|

| Food Packaging | PE / PP | 2% – 5% | Prevents condensation on inner surfaces of refrigerated food packaging, maintaining product visibility and enhancing display appeal. |

| Agricultural Greenhouse Films | PE / EVA | 3% – 5% | Reduces fog droplet shading, increases light transmission, and promotes plant growth. |

| Industrial & Consumer Packaging | PP / PET | 2% – 4% | Prevents moisture adhesion on transparent containers or inner film surfaces, maintaining visual clarity. |

| Medical & Electronics | PET / PC | 3% – 6% | Prevents fogging on instrument covers or displays, improving visibility and safety. |

“Types of Antifog Masterbatch ”

”

Various types of anti-fog masterbatches can maintain high transparency and visual clarity in finished products.

Migratory Antifog Masterbatch: By incorporating migratory antifog agents, these compounds gradually migrate to the surface during product use. They adsorb moisture from the air and form a uniform water film to achieve anti-fog functionality. They offer rapid onset and low cost, but their anti fog effectiveness diminishes over time. They are commonly used in short-term food packaging films and disposable films.

Permanent Anti Fog Masterbatch: Forms a stable hydrophilic conductive structure within the material, maintaining long-term anti-fog performance without relying on migration. Less affected by humidity and time, it offers enduring antifog properties but carries slightly higher costs. Commonly used in greenhouse films, long-term storage packaging, and automotive transparent components.

Hybrid Antifog Master batch: Combining the advantages of migration-type and permanent-type masterbatches, it delivers pronounced initial anti fog effects while maintaining long-term stability. Offering balanced performance and moderate cost, it suits diverse applications. Commonly used in medium-to-long-term packaging films, transparent cover films, and industrial protective films.

antifog Masterbatches in Plastic

Exterior mirrors of Automobiles

Exterior mirrors of Automobiles Consumer Packaging

Consumer Packaging Medical Plastic Protective Cover

Medical Plastic Protective Cover

Food Packaging

Food Packaging Agricultural Greenhouse Films

Agricultural Greenhouse Films

How to choose antifog master batch

- Based on usage cycle: Migratory masterbatches are recommended for short-term or single-use packaging, while permanent or composite masterbatches are suitable for long-term use or high-humidity environments.

- Matching substrate systems: Select masterbatches with the same carrier type as the substrate (e.g., PE carrier for PE film) to enhance dispersion and compatibility.

- Operating environment humidity and temperature: High-humidity condensation scenarios (e.g., refrigerated packaging, greenhouse films) require masterbatches with higher anti-fog component content.

- Optical and Transparency Requirements: For products demanding high light transmittance, use low-color-difference, light-colored transparent masterbatches.

- Process Compatibility: Blown film, cast film, or injection molding processes suit masterbatches with different melt indices, select based on process parameters.

- Quality Suppliers: Prioritize professional masterbatch manufacturers offering performance testing, formulation adjustments, and technical support for stable, reliable antifog performance.

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.