Antiblock Masterbatch

Antiblock masterbatch is an inorganic micro-particle uniformly dispersed within plastic films. It forms microscopic protrusions on the plastic surface, reducing the actual contact area between layers of film or plastic sheets. This effectively prevents adhesion during processing and storage, enhancing product quality. Anti-block masterbatch eliminates film adhesion issues and is commonly used in packaging films, films, sheets, and various other industries.

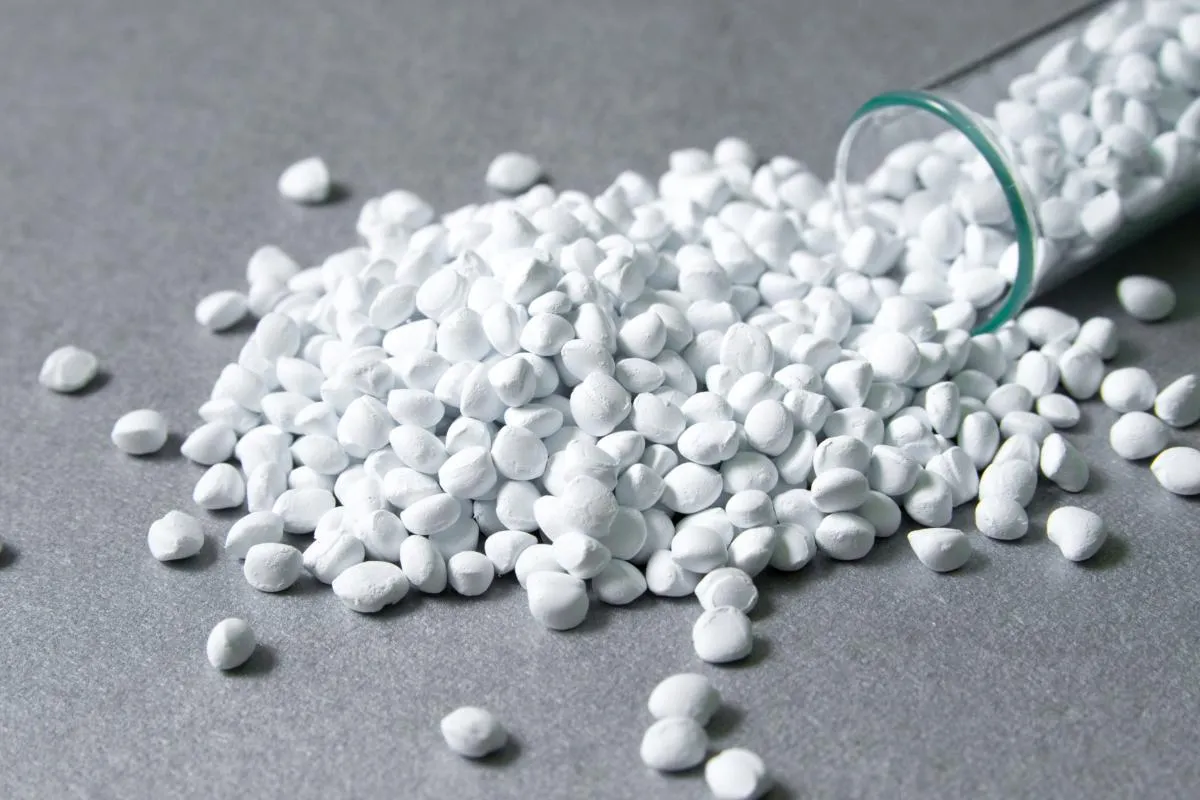

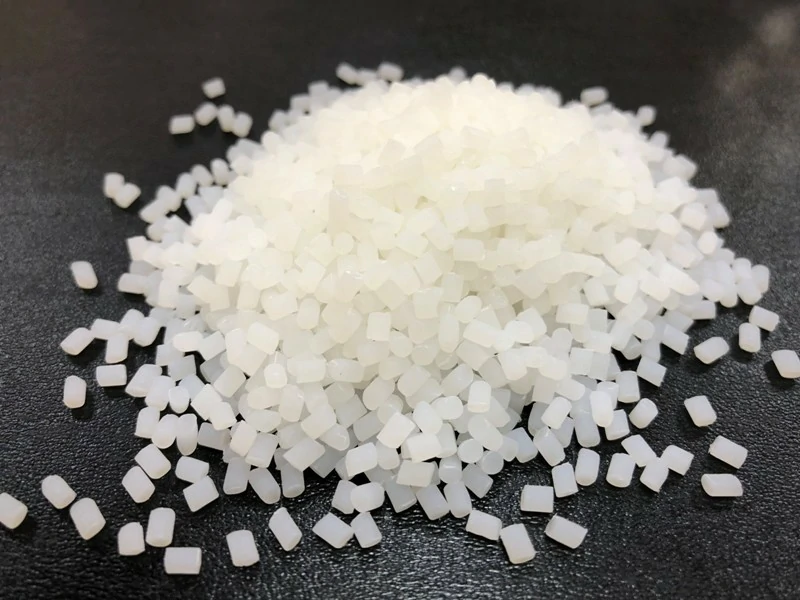

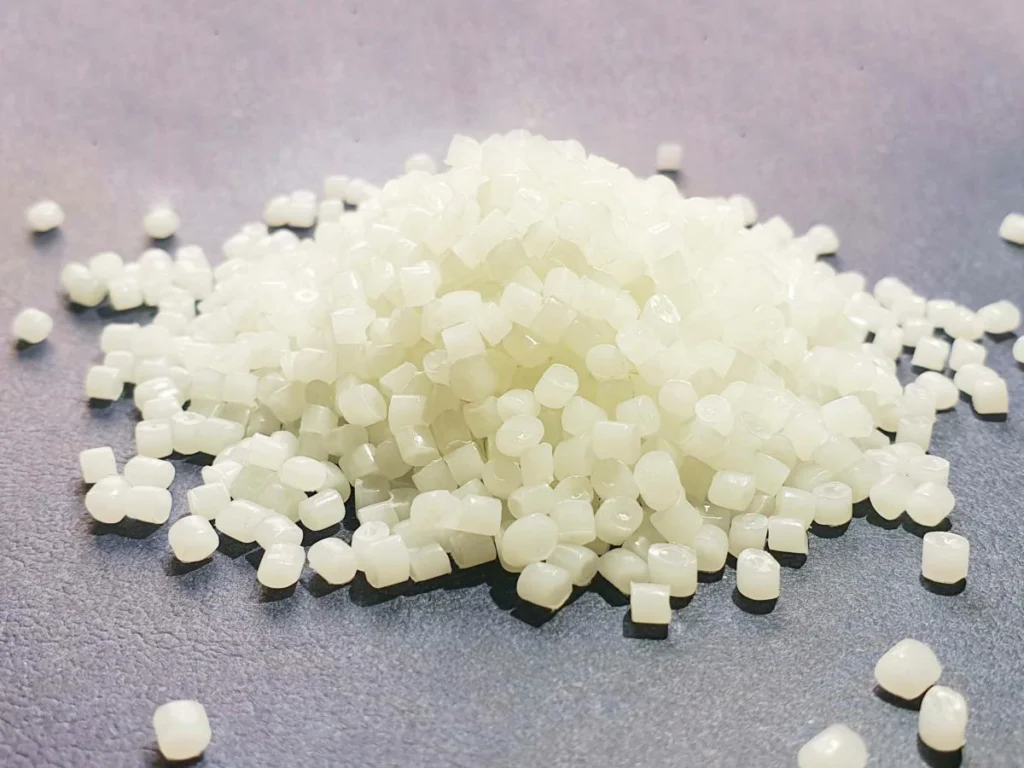

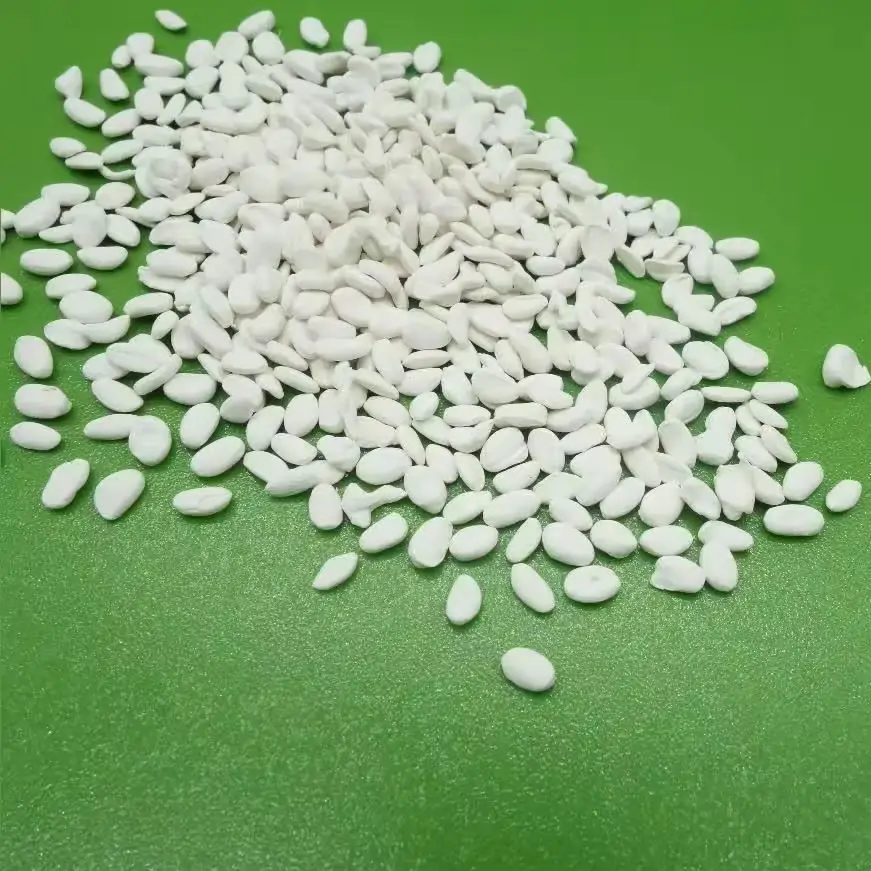

- Color: White, milky white, light-colored pellets

- Suitable Base Materials: PE, PP, PET

- Applicable Plastic Processing Methods: Blown film, cast film, extrusion, injection molding, multi-layer co-extrusion

- Minimum Order Quantity: 1 ton

- Sample: Free 1 kg sample

- Customization: Acceptable

- Delivery Time: 7 days after order confirmation

- Payment Terms: T/T, L/C

aDVANTAGES

Choose Antiblock master batch to prevent bubble formation and film adhesion

High stability

Maintains stable dispersion at high temperatures without migration or surface defects like white spots or blotches, ensuring uniform and attractive film appearance.

Reduces adhesion issues

Significantly decreases interlayer contact area, maintaining excellent peelability after winding and stacking to prevent tearing or separation difficulties.

Minimal Impact on Transparency

Utilizes ultra-fine inorganic particles to preserve excellent clarity and gloss, suitable for food packaging films, daily chemical product packaging films, etc.

Enhanced Processing Efficiency

Excellent slip properties during extrusion, blow molding, and packaging processes prevent equipment adhesion, reducing downtime and scrap while boosting overall production efficiency.

Versatile Process Compatibility

Suitable for multiple processes including blown film, cast film, and extrusion, offering flexible application across diverse plastic product requirements.

Cost-effective

Reduces costs by minimizing equipment wear from adhesion, labor expenses, and storage consumption, while improving finished product quality and efficiency.

Specifications

| Product name | Antiblock masterbatch |

|---|---|

| Carrier Resin | PE / LDPE / PP/PS/PC/PET |

| Anti-block Content | 2% – 15% (Customised) |

| Melt Flow Index(190°C/2.16kg) | 0.5 – 10 g/10 min |

| Recommended Dosage | 2% – 6% |

| Anti-block Particle Type | Silica, Talc, etc. |

| Density | 0.9 – 1.3 g/cm³ |

| Moisture Content | ≤ 0.3% |

| Thermal Stability | 180–280℃ |

| Appearance | White or slightly translucent granules |

| Particle Size | 2–3 μm, 4–6 μm |

| Packaging | 25kg/bag |

| Storage Conditions | cool and dry place |

Customized Antiblock Masterbatch

Huashuo can customize Antiblock colour masterbatches according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, PET, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

“Types of Antiblock Masterbatch”

Multifarious anti-block masterbatch types to address film and sheet adhesion issue

General Antiblock Masterbatch: Utilizes inorganic particles of conventional particle size, offering excellent compatibility and high cost-effectiveness. Widely used in PE/PP packaging films, garbage bags, and general industrial films.

High-Transparency Anti-Block Master batch: Utilizes ultra-fine anti-block particles to significantly reduce impact on film transparency and gloss. Suitable for food packaging films, daily chemical packaging films, BOPP/CPP films, etc.

High-Temperature Resistant Anti-Block Masterbatch: Designed for high-temperature film processing (e.g., high-speed blown film, cast film) without migration or decomposition. Commonly used in high-temperature environments to enhance performance stability.

Food-Grade Antiblock Master batch: FDA-certified for packaging materials in direct or indirect food contact, such as freshness bags, freezer bags, and food packaging films.

Applications of Antiblock Masterbatches

Anti-block color masterbatch is suitable for various processing techniques and is widely used in diverse films, sheets, and packaging materials. Its primary application areas are as follows:

Packaging Films: Used in food packaging films, daily chemical packaging films, continuous roll bags, etc., to enhance film tearability, ensuring smooth and efficient packaging processes.

Agricultural Films: Suitable for greenhouse films, mulch films, and insulation films, preventing film adhesion, improving installation efficiency, and enhancing practical performance.

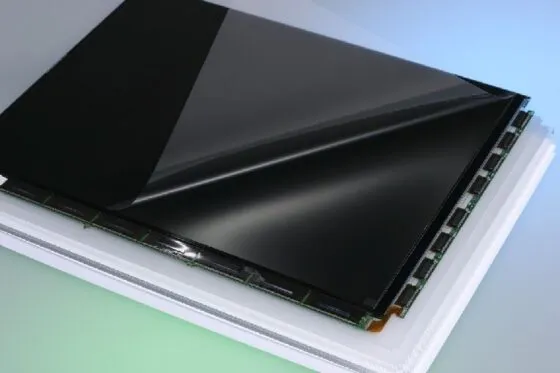

Industrial Protective Films: Used for surface protection films on building materials, home appliances, electronics, etc., preventing adhesion during winding or storage and improving installation efficiency.

Plastic Bags: Used in garbage bags, shopping bags, shipping bags, etc., improving bag manufacturing efficiency and preventing finished product stacking adhesion that causes packaging jams.

Plastic Sheets: Suitable for sheets, trays, deep-drawn packaging, and other items prone to surface adhesion. Prevents sticking during stacking and improves usability.

Cast Film and Blown Film: Applicable to various single-layer and multi-layer co-extruded films. Enhances surface slip and tear resistance.

antiblock Masterbatchs in Plastic

food packaging films

food packaging films sheets materials

sheets materials electronic protective films

electronic protective films

agricultural-mulch-film

agricultural-mulch-film shopping bags

shopping bags

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.