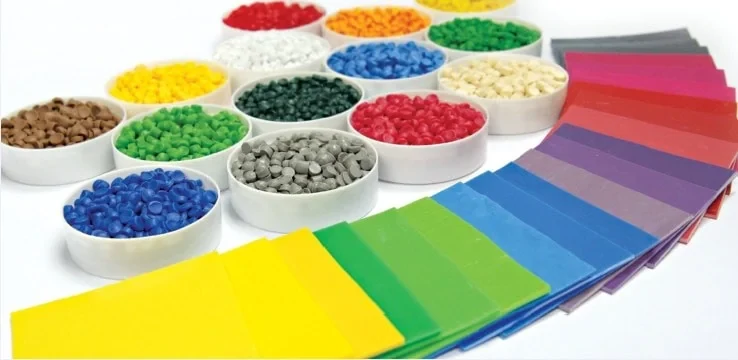

PVC Masterbatches

PVC masterbatch is a high-performance coloring material formulated by uniformly compounding high-concentration pigments, dispersants, and other additives into a polyvinyl chloride resin carrier. It delivers stable, uniform color performance with high coverage while enhancing processing stability and surface quality. Commonly used in PVC pipes, profiles, wires and cables, sheets, and other applications.

- Colors: Red, Blue, Yellow, Green, White, Black, Grey, Transparent, Customized colors

- Additives: UV stabilizers, Heat stabilizers, Lubricants, Anti-migration agents, Antioxidants

- Application Processes: Extrusion, Injection molding, Blow molding, Calendering, PVC film/sheet processing

- Minimum Order Quantity: 1 ton

- Sample: Free 1 kg sample

- Customization: Acceptable

- Delivery Time: 7 days after order is confirmed

- Payment Terms: T/T, L/C

Composition of PVC Color Masterbatches

The formulation of PVC masterbatches primarily consists of the following components:

PVC Resin Carrier: Utilizes PVC resin with high compatibility to the final product as the carrier, enhancing the flowability and dispersion properties of the masterbatch during processing.

High-Performance Pigments: Heat-resistant, light-resistant, and migration-resistant organic or inorganic pigments are selected to ensure stable product color, high hiding power, and fade resistance.

Dispersants: Improve pigment wetting and dispersion within the PVC resin, ensuring uniform distribution throughout the matrix. This reduces pigment agglomeration and enhances product surface finish.

Functional Additives: Select functional components such as heat stabilizers, UV stabilizers, migration inhibitors, and lubricants based on requirements to enhance the long-term durability of products.

PVC Resin Carrier

PVC Resin Carrier High-Performance Masterbatch Pigments

High-Performance Masterbatch Pigments Colour Dispersing Aids

Colour Dispersing Aids PVC-Compounds

PVC-Compounds

Advantages

- Superior Dispersibility: Pigments are uniformly distributed within the PVC matrix, resulting in products free of color spots, impurities, or streaks. Ideal for applications like pipes and cable compounds.

- Enhanced Aesthetic Quality: Improves product brightness, hiding power, and surface smoothness, boosting market appeal and competitiveness of end products.

- High Heat Resistance: Pigment and stabilizer formulations withstand sustained high temperatures during PVC extrusion without decomposition, charring, or discoloration, ensuring stable production.

- Broad Applicability: Suitable for both rigid PVC (UPVC) and flexible PVC, compatible with extrusion, injection molding, calendering, and other forming processes without additional formulation adjustments.

- Reduced Production Costs: Masterbatches offer easier metering than powder pigments, ensuring precise and consistent coloration. This minimizes pigment waste, reduces color variation, and improves production yield.

- Environmentally Safe: Formulated to meet RoHS, REACH, and heavy-metal-free standards, these products are safe for food packaging and medical-grade PVC applications.

PVC-Masterbatch

PVC-Masterbatch Masterbatch for PVC

Masterbatch for PVC Food-Grade-PVC-Masterbatch

Food-Grade-PVC-Masterbatch

Common Types of PVC Colour Masterbatches

General-type PVC Masterbatches: Wide applicability and low cost, extensively used in standard pipes, profiles, cable compounds, etc.

High-Coverage Color Masterbatches: Strong coverage and high stain resistance, suitable for thick-walled products, cable jackets, etc.

Weather-Resistant Masterbatches: UV and light-resistant properties, commonly used in outdoor profiles, building materials, etc.

Food-Grade/Medical-Grade Color Masterbatch: High purity, low migration, heavy metal-free; used in food and medical packaging.

Pearlescent/Metallic Color Masterbatch: Vibrant effects with high visual appeal, primarily used in premium packaging and home decor products.

Flame-Retardant PVC Master batch: Incorporates flame-retardant properties for enhanced safety, suitable for wires, cables, and electronic materials.

Specifications

| Test Item | Specification Data |

|---|---|

| Product name | PVC Masterbatch |

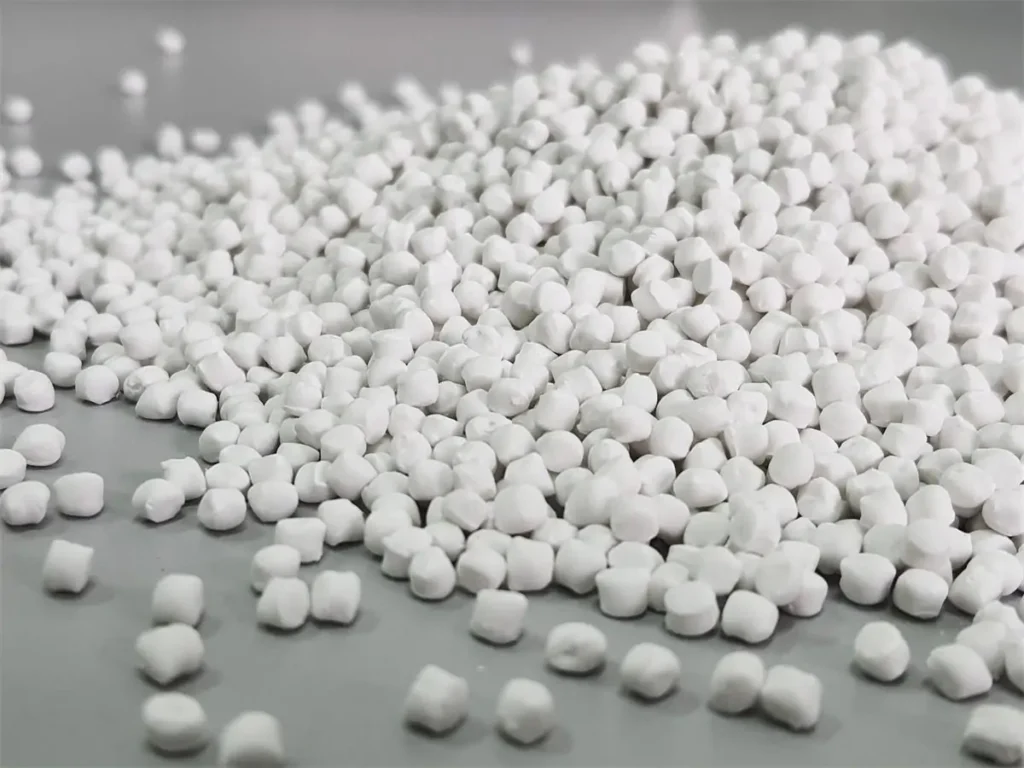

| Appearance | Uniform color,no impurity granular |

| Color | Red/Yellow/Blue/White/Green(Customized) |

| Particle Size | 2.0×3.0mm |

| Carrier | PVC/UPVC |

| Density | 1.25–1.65 g/cm³ |

| Heat Resistance (℃) | 160–280°C |

| Moisture Content | ≤0.1% |

| Dosage Ratio | 1%–5% |

| Pigment Content | 20%–60% |

| Suitable Processes | Extrusion/Injection Molding/Calendering/Blow Molding |

| Packaging | 25kg/bag (OEM/ODM supported) |

The above are partial parameters of PVC master batch for reference. If you are interested in our color masterbatch or would like to learn more about PVC masterbatch market price and other information, please contact us. We will answer your questions and provide customized formulation services.

Customized PVC Masterbatches

Custom PVC color masterbatch requires the following information from you:

- Final product type: e.g., blown film, injection molded, extrusion etc.

- PVC base material used: e.g., pvc or others.

- Target color standard: Provide Pantone color number, RAL color number, or physical color sample.

- Color fastness requirements: Such as migration resistance, lightfastness (UV resistance), heat resistance rating.

- Processing method and temperature: e.g., film blowing (160-200°C), injection molding (180-210°C), etc.

- Special Functions: Require additional properties such as antistatic, antioxidant?

Our color masterbatch experts will contact you within 2 hours to provide complimentary color matching solutions and comprehensive technical support!

“PVC Masterbatchs in Different Industries ”

”

– PVC colour master batch is widely used in the following fields

PVC Pipes & Fittings: Commonly used for water supply and drainage pipes, electrical conduits, agricultural irrigation pipes, etc. Features strong coverage, high weather resistance, and long-lasting color retention.

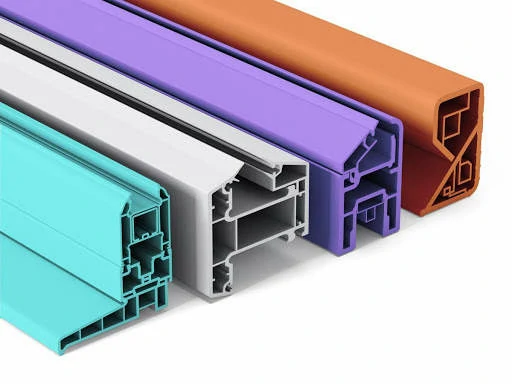

PVC Profiles: Suitable for door and window profiles, wall paneling, decorative trim, and other outdoor products. Maintains color stability in prolonged outdoor environments.

PVC Cable & Wire Sheath: Used as insulation and sheathing material, providing heat resistance, flame retardancy, and migration resistance to enhance long-term durability.

PVC Foam Products & Injection Molded Parts: Applied in advertising boards, architectural decorative panels, and home appliance components, offering strong light resistance while enhancing color uniformity and durability.

Soft PVC Products: Commonly used in transparent hoses, toys, footwear materials, and sealing strips, featuring excellent dispersion and vibrant colors.

PVC Films & Sheets: Primarily used for packaging films, advertising films, packaging sheets, and transparent sheets, featuring uniform color and a smooth surface.

PVC Masterbatchs in Plastic

PVC color master batch enhances melt stability and color uniformity during processing, resulting in aesthetically pleasing products and smoother processing. It is suitable for various processing techniques on both rigid and flexible PVC, improving the market appeal of finished products.

PVC-Profiles

PVC-Profiles Wire Sheath

Wire Sheath PVC Sheets

PVC Sheets

PVC Films

PVC Films PVC Pipe

PVC Pipe

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.