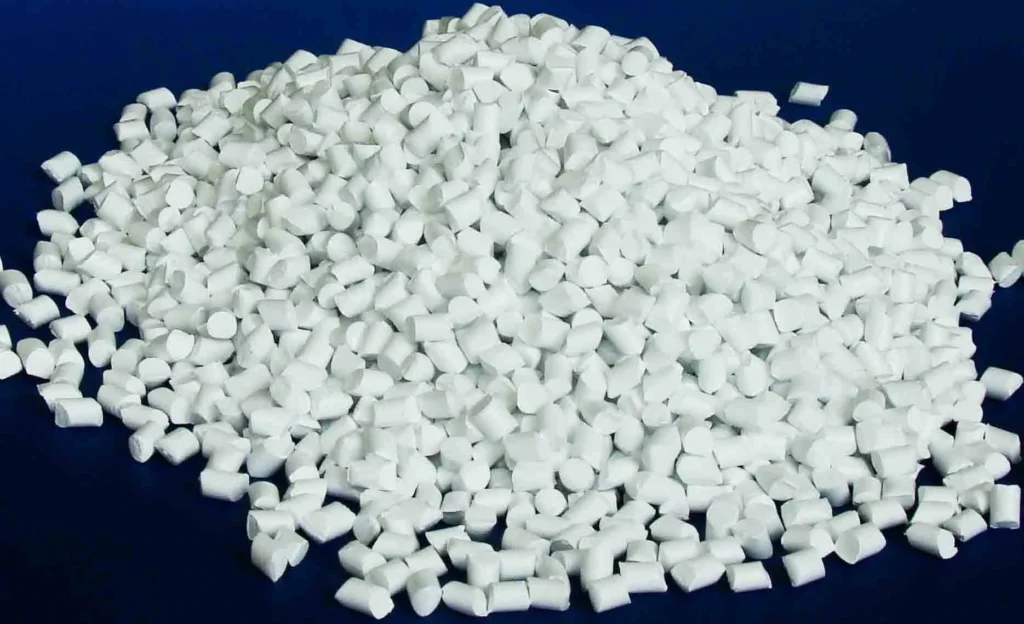

Polycarbonate (PC) master batch is an engineering plastic renowned for its high transparency, high impact strength, and excellent thermal stability. It finds extensive applications in electronics, automotive components, lighting, and optical products. However, due to PC’s inherent high viscosity, high processing temperatures, and sensitivity to pigment systems, coloring processes often encounter issues such as significant color variation, poor dispersion, black spots, flow marks, and unstable brightness.

PC masterbatch, as a common coloring method, enhances production efficiency and color stability. However, improper formulation or process control can also lead to a series of coloring defects. Therefore, below we will explore PC coloring issues and their causes, along with feasible solutions.

PC Masterbatch Coloring Issues and Reasons

Below are common PC color masterbatch coloring problems and their root causes. Let’s examine the following:

Yellowing / Darkening Issues

Transparent or light-colored parts exhibit yellowing, overall darkening, and reduced light transmission. These effects intensify with increased processing temperature or dwell time.

Primary reasons:

1. Thermal decomposition of pigments or additives: Insufficient thermal stability of pigments, dispersants, or certain additives causes thermal decomposition or oxidation during PC’s high-temperature processing (260–300°C), producing yellow byproducts.

2. Thermal oxidation or hydrolysis of PC base material: PC undergoes thermal oxidation/hydrolysis under high temperatures or moisture, generating chromophores that cause intrinsic yellowing of the material.

Color Inconsistency / Batch Variation

Finished product color depth or hue varies across different batches, machines, or molds using the same formulation, with ΔE exceeding customer tolerance limits.

Primary reasons:

1. Masterbatch-substrate mismatch: Masterbatch carrier is non-PC or exhibits significantly different melt flow index from the substrate, leading to uneven melt blending and colorant concentration distribution.

2. Ingredient variation and metering fluctuations: Insufficient precision in automated dosing or manual addition variations cause unstable masterbatch addition ratios, triggering color differences.

Poor dispersion: Color spots, patches

Visible particles, black spots, streaks, or localized haze areas appear on the product surface, increasing haze in optical components.

Primary reasons:

1. Pigment agglomeration or excessive particle size: Inadequate pigment grinding or improper masterbatch dispersion system design prevents agglomerates from breaking down and dispersing in the melt.

2. Insufficient shear or temperature: Inadequate shear force or melt temperature during extrusion or injection molding fails to uniformly disperse pigments into the base material.

Black Spots / Burnt Specks

Small black particles or scorch marks appear on the surface or cross-section of products, more noticeable on transparent or light-colored items. These are typically localized carbonized particles, often leading to scrap or return risks.

Primary reasons:

1. Localized overheating and carbonization: Extended residence time in the barrel, hot runner, or screw causes excessive temperature, resulting in localized overheating and carbonization of some material.

2. Contamination of Raw Materials or Equipment: Masterbatch or base material contaminated by organic impurities, metal shavings, or residues from previous batches decomposes or carbonizes at high temperatures, forming black spots.

3. Moisture-Induced Carbonization: Water-containing melt undergoes violent vaporization at localized high-heat points, causing localized explosions and carbonizing surrounding material.

Loss of Transparency / Gloss

PC parts that should be transparent or high-gloss exhibit haze, dullness, surface roughness, or noticeable scattering, resulting in poor gloss and reduced transparency.

Primary reasons:

1. Inappropriate Pigments or Fillers: Inorganic fillers or pigments mismatched with PC’s refractive index cause light scattering, lowering light transmission.

2. Uneven dispersion or micro-bubbles: Pigment agglomeration, moisture content, or volatile substances form bubbles, impairing light transmission.

3. Surface oxidation or micro-carbonization: High temperatures cause micro-damage or oxidation layers on the surface, reducing surface gloss.

Above, we have examined the coloring issues that arise in PC colour masterbatches and their causes. Below, we will explore potential solutions.

Solutions for PC Masterbatch Coloring Issues

The following solutions for PC master batch coloring issues are provided for reference, applicable to factory production and material selection practices.

Choose high-heat-resistant pigment systems specifically designed for PC

Reduce yellowing and enhance color stability during high-temperature injection molding.

- Select organic pigments (e.g., high-performance phthalocyanine blue, azo pigments) or inorganic pigment systems with heat resistance ≥300°C to prevent color changes during high-temperature processing.

- Avoid using low-temperature pigments prone to decomposition to maintain color stability during injection molding, extrusion, and other processes.

Optimize masterbatch dispersion systems and formulation design

Reduce color spots and blotches while improving optical properties and surface uniformity.

- Employ PC-specific carriers (same material) to enhance compatibility and facilitate uniform pigment distribution within PC.

- Utilize high-efficiency dispersants and lubrication systems to lower melt viscosity and increase pigment opening rate.

- For high-transparency applications, use ultrafine pigment particles (≤1μm) and control particle size to minimize dispersion irregularities.

Control processing techniques and equipment conditions

Minimize typical processing defects such as yellowing, water streaks, silver streaks, and black spots.

- Enhance resin and masterbatch drying—typically 3–4 hours at 120°C—to prevent silver streaks and water streaks.

- Maintain injection molding temperatures between 260–300°C to prevent poor dispersion at low temperatures or scorching at high temperatures.

- Enhance hot runner cleaning, inspect barrel dead zones, and reduce carbonization caused by prolonged residence times.

Choose high-concentration or high-quality color masterbatches

Improve color consistency and reduce color variation risks in large-scale production.

- High-concentration (50%-80%) PC color masterbatch helps reduce filler ratios and improve color uniformity.

- For premium appearance parts, use dual-color masterbatch or optical-grade masterbatch to enhance brightness and transparency.

- Select suppliers with consistent batches and mature production lines to minimize color variation sources.

Organic Pigment

Organic Pigment Yellow-Pigment-PC-masterbatch

Yellow-Pigment-PC-masterbatch PC Organic Masterbatch

PC Organic Masterbatch PC Masterbatch

PC Masterbatch PC Masterbatch

PC Masterbatch Masterbatch for PC

Masterbatch for PC

We have now covered PC color master batch coloring issues, their causes, and solutions. Should you require assistance or have further questions, please contact us to resolve your concerns. Below are some additional recommendations for reference.

Recommendations

- Confirm PC application performance requirements in advance: Different applications have varying demands for transparency, heat resistance, and optical properties. Communicate with masterbatch suppliers during the initial material selection phase to confirm parameters, thereby avoiding costly adjustments later.

- Conduct sample testing and establish ΔE color difference standards: Confirm color targets with users, perform multiple small-scale trials before mass production, and establish ΔE color difference control standards. This ensures subsequent batches remain stable and controllable, reducing production risks.

- Optimize production environment and storage conditions: Perform screw cleaning, hot runner inspections, and hopper filtration before production. Since both PC resin and masterbatch readily absorb moisture, store them in dry, dust-free, and light-protected conditions to prevent carbonization and moisture-induced black spots.

- Select an experienced PC colour master batch supplier: An experienced supplier can customize color, heat resistance, and dispersion systems for specific applications, helping reduce trial-and-error costs and cycles.

Preparation

Preparation PC Yellow Masterbatch

PC Yellow Masterbatch Masterbatch for PC

Masterbatch for PC Record

Record

By understanding this information, we can solve the problem of PC masterbatch coloring more effectively.

Conclusion

This article discusses the coloring problems and causes of PC masterbatch, as well as solutions. Masterbatch PC has wide applications in the plastics industry. If you are interested, please contact us for detailed information and customized solutions.