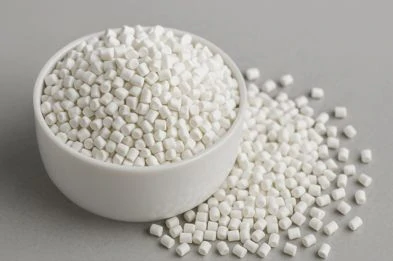

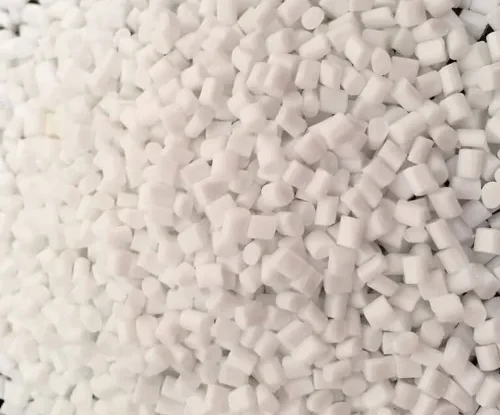

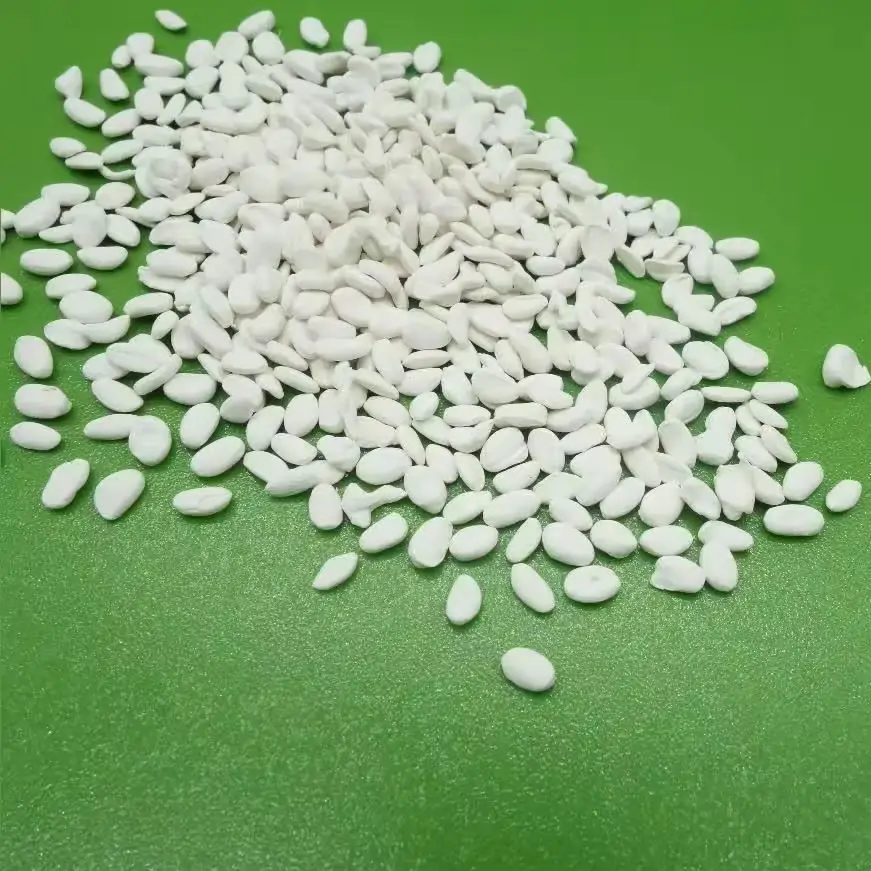

White color masterbatch is a plastic colour concentrate pellet primarily composed of titanium dioxide (TiO₂) as the pigment. It is manufactured by processing carrier resins such as PE and PP with dispersing additives. During plastic moulding, it imparts high whiteness, high brightness, and excellent coverage to the finished product while maintaining colour stability.

Compared to powdered pigments, white masterbatch offers advantages such as environmental friendliness, precise metering, and uniform dispersion, making it widely adopted in the plastics processing industry. Let us now explore its properties. First, consider its key benefits.

Advantages of White Color Masterbatch

High Opacity and Brightness: Utilizing rutile-type TiO₂, it imparts a bright, pure white hue to products, achieving high coverage with minimal addition.

Superior Dispersibility: Through high-mixing processes, pigments disperse uniformly, minimizing colour spots and preventing streaks, blotches, or uneven whiteness.

Convenient Production Handling: The granular form facilitates precise metering and blending, reduces dust dispersion, maintains workshop cleanliness, and enhances processing efficiency.

Superior Heat Resistance: Exhibits excellent processing temperature tolerance and heat resistance, with minimal yellowing. Suitable for high-temperature processes, including injection moulding and blow moulding.

Cost-Effective: Scientifically formulated to match requirements and white color masterbatch characteristics, reducing pigment wastage. Consistent whiteness minimizes overall production costs.

White Color Masterbatch

White Color Masterbatch White Color Masterbatch

White Color Masterbatch White Color Masterbatches

White Color Masterbatches

White masterbatches offer numerous advantages and are extensively used across the plastics industry. But what types exist? Let us explore the common varieties.

Common Types of White Colour Masterbatches

High Opacity White Color Masterbatch

Typically contains a high proportion of rutile TiO₂, delivering strong coverage in thin-walled products or transparent materials. Widely used in film blowing, injection moulding, and sheet extrusion.

General Purpose White Masterbatch

Offering moderate whiteness with significant cost advantages, it features excellent dispersion and melt flow suitable for various processing techniques. Commonly used in standard plastic products such as packaging films and daily-use injection-moulded components.

Food Contact White Colour Masterbatch

Certified to FDA and EU 10/2011 regulations, featuring low odour, low migration, and environmentally friendly properties free from harmful substances. Commonly used in products such as drinking straws, food packaging films, and meal containers.

High Temperature Resistant White Master batch

Compatible with engineering plastics, including ABS, PA, PC, and PET, resisting yellowing or decomposition during high-temperature processing. Commonly employed in automotive interiors, appliance casings, and electronic components.

Recycled Material White Color Masterbatch

Addresses the common yellowish or dull appearance of recycled materials. Enhances the whiteness and gloss of recycled products through masterbatch addition, boosting market appeal.

White masterbatches come in diverse types, suited to various application fields and scenarios. Below, we explore the specific industries where they are utilized.

Industries Utilizing White Color Masterbatches

Packaging Films (PE/PP Film): Commonly employed in shopping bags, food packaging films, and agricultural films to enhance brightness, whiteness, and light-blocking properties, thereby improving film aesthetics.

Injection Moulded Products (Injection Moulding): Suitable for household goods, toys, storage boxes, etc. Ensures product safety and environmental compliance with a bright white surface and minimal colour variation.

Pipe & Sheet Extrusion: Widely employed in PPR pipes, PVC pipes, and sheets, providing high opacity, enhanced weather resistance, and extended product lifespan.

Blow Moulded Bottles: Commonly used for detergent bottles, cosmetic containers, etc., enhancing whiteness and overall aesthetics to boost market appeal.

Engineering Plastics: Widely employed in electronic casings and automotive interior/exterior components, delivering bright whiteness and heat resistance to prevent yellowing, ageing, and colour fading.

Food-Packaging-Films

Food-Packaging-Films Injection Molding

Injection Molding Pipe Extrusion

Pipe Extrusion Blow Moulding Bottles

Blow Moulding Bottles Agricultural Films

Agricultural Films Electronic Casings

Electronic Casings

White color masterbatch, with its white hue, enjoys broad application and popularity across industries. However, what should we consider when selecting a suitable supplier?

How to Select the Right White Color Masterbatch Supplier

- Raw Material Quality: Utilizes high-grade rutile titanium dioxide (Rutile TiO₂) and stable carrier resins to enhance product whiteness, opacity, and weather resistance.

- Dispersion and Production Processes: Mature technologies, including twin-screw extrusion, high-shear compounding, and automated metering systems, ensure excellent masterbatch dispersion and superior finished product appearance.

- Food-Grade and Environmental Certifications: For applications in food packaging or daily necessities, suppliers should provide relevant compliance certificates such as FDA, RoHS, and REACH.

- Customized Solutions: Tailor TiO₂ content, carrier resin, melt flow index, and temperature resistance grades to client requirements, delivering bespoke solutions.

- Manufacturing Capabilities: Select manufacturers with stable production capacity, export experience, and technical support to ensure reliable supply and minimize trial material and production risks.

The above outlines key considerations when selecting a reliable masterbatch supplier for your reference. Should you have any queries regarding colour masterbatches, please do not hesitate to contact us for consultation.

Conclusion

Through the preceding discussion, we have explored the advantages of white color masterbatch, its common types, application domains, and how to select a suitable masterbatch manufacturer. Should you be seeking high-quality, customizable white masterbatch, please contact us. We shall provide you with the optimal solution.