White masterbatch serves as a coloring and functional additive for plastic products. However, during processing, issues such as unstable whiteness, yellowing, color spots, and processing difficulties may arise. This article explores the primary problems encountered with white plastic masterbatch and provides corresponding solutions. Let’s take a look.

Common Problems with White Plastic Masterbatch

White color masterbatch is suitable for various processing techniques such as film blowing, injection molding, and extrusion. However, several issues often arise when using white plastic masterbatch. Below, we will examine these problems in detail.

Insufficient Whiteness

- Some molded products exhibit a grayish or dull appearance after forming, or the base color shows through, resulting in poor overall visual quality. This issue is more pronounced in films and light-colored injection-molded parts.

- Inadequate TiO₂ Content or Inappropriate Type: When the TiO₂ content in the white master batch is insufficient, or the crystal form is poorly selected, it compromises the whiteness and coverage of the finished product.

- Poor TiO₂ Dispersion: Even with sufficient TiO₂ content, inadequate dispersion prevents the formation of a stable, uniform light-scattering structure. This results in uneven whiteness, with localized areas appearing grayish or dull.

Yellowing Phenomenon

- White products may exhibit yellowing after high-temperature processing or prolonged storage, commonly observed in injection-molded parts, high-temperature extruded items, and products subjected to long-term use.

- Titanium Dioxide Impurities or Poor Heat Resistance: Elevated metal impurity content in titanium dioxide or inadequate surface coating treatment can trigger photocatalytic reactions at high temperatures, causing gradual yellowing of the product.

- Poor formulation stability: Incompatibility between white plastic masterbatch and base resin, or unstable additive systems at high temperatures, accelerates color changes and compromises finished product appearance.

Black Spots, White Spots, or Streaks

- Particulate texture, streaks, or bright spots on product surfaces reduce aesthetic quality, diminish end-user acceptance, and lower market competitiveness.

- Titanium Dioxide Agglomeration: Poor TiO₂ dispersion readily forms micro-agglomerates, manifesting as color spots or streaks on product surfaces.

- Compounding Process: Insufficient compounding intensity during masterbatch production or unstable process control can cause batch-to-batch variations, compromising finished product appearance and quality.

Unstable Processing Performance

- Some white masterbatches may exhibit fluctuating extrusion pressures, unstable film blowing, or uneven injection molding filling during use, disrupting continuous production and reducing equipment efficiency.

- Inadequate Carrier Resin Compatibility: A Mismatch between the carrier resin and the actual substrate resin can reduce melt flowability, increasing processing difficulty.

- Poor Batch Stability: Performance fluctuations in masterbatch are amplified during production, leading to frequent machine adjustments, increased scrap rates, and higher overall production costs.

White colour masterbatch has broad applications but may encounter the above issues, requiring corresponding solutions. Below, we explore how to resolve white plastic masterbatch challenges.

Solutions for White Plastic Masterbatch

Addressing white color master batch issues primarily involves selecting suitable raw materials, optimizing process control, and refining formulation design to enhance its stable performance during processing. The following solutions are proposed.

Choose TiO₂ White Plastic Masterbatch Based on Application Scenarios

Different products and applications demand varying levels of whiteness, hiding power, and weather resistance. Select rutile or anatase TiO₂ white masterbatch appropriately and control the addition ratio to meet appearance requirements while reducing costs.

Improve Titanium Dioxide Dispersibility

Employ high-torque mixing equipment and mature dispersion systems to ensure uniform distribution of TiO₂ within the resin. This effectively reduces black spots, white spots, and streaks, enhances product surface smoothness, and improves overall processing stability.

Optimize heat resistance and anti-yellowing properties

Select high-purity, low-impurity TiO₂ with well-treated surface coatings to reduce photocatalytic activity and heat sensitivity. Resists yellowing during high-temperature processing and long-term use, suitable for applications demanding high color stability.

Adopt customized solutions

Generic white plastic masterbatches cannot accommodate all processing conditions. Formulations tailored to your resin type, processing methods, and end-use applications systematically address issues like whiteness, dispersion, and processing stability.

White Plastic Masterbatch

White Plastic Masterbatch White Plastic Masterbatch

White Plastic Masterbatch White Plastic Masterbatch

White Plastic Masterbatch

We’ve briefly covered solutions for white masterbatch challenges. If you have any questions or requirements, feel free to contact us or select a reputable supplier.

Choosing the Right White Plastic Masterbatch Supplier

When choosing a high-quality supplier, their manufacturing capabilities and stability also play a crucial role. A reputable masterbatch white manufacturer typically possesses the following advantages:

Stable Raw Material Supply: Consistent titanium dioxide supply ensures batch-to-batch stability in masterbatch production, preventing fluctuations in whiteness or performance caused by raw material variations.

Mature Compounding and Dispersion Processes: Advanced compounding equipment and refined process control facilitate efficient TiO₂ dispersion, minimizing color spots and streaking issues.

Comprehensive Quality Testing: Systematic evaluation of whiteness, dispersion, yellowing resistance, and other metrics ensures consistent and controllable performance across every batch of white masterbatch.

Customized Solutions: Opt for suppliers with technical support capabilities who provide tailored solutions based on specific application conditions, reducing trial-and-error costs.

Professional China white plastic masterbatch suppliers not only deliver premium masterbatches but also create sustained value for customers through long-term partnerships.

Conclusion

This article outlines common challenges in white masterbatch processing, corresponding solutions, and criteria for selecting quality suppliers. For inquiries or interest in our masterbatches, please contact us.

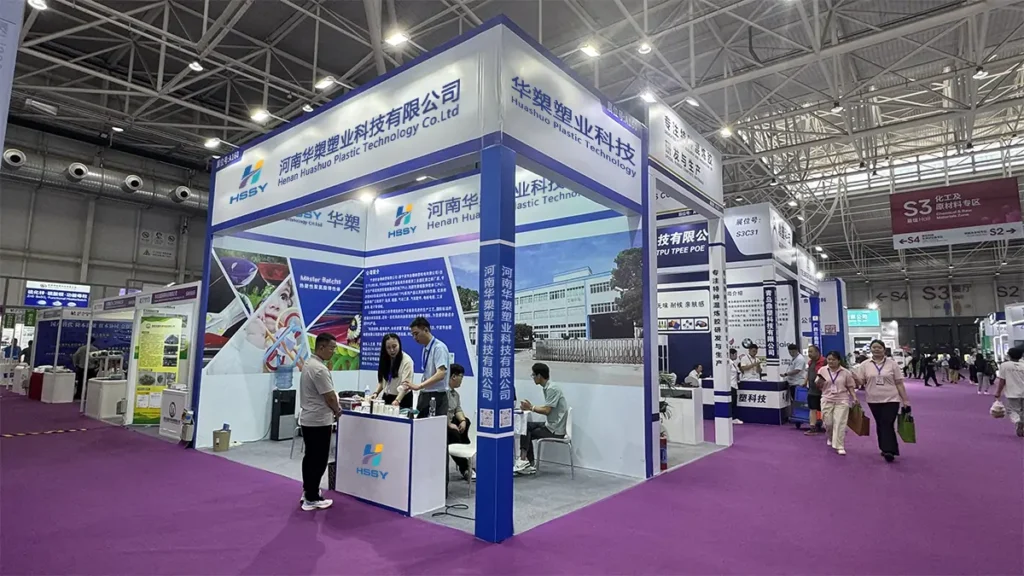

As a professional white color masterbatch manufacturer, Huashuo Color Masterbatch is committed to delivering stable, efficient white plastic masterbatch solutions to help customers overcome challenges.