In the automotive industry, color masterbatches are widely used in the manufacturing of plastic components such as grille radiator, headlight covers, dashboards, bumpers, interior trim panels, and door handles. By incorporating color masterbatches, automotive plastic parts achieve consistent coloring while enhancing weather resistance, anti-aging properties, and surface gloss. This meets the stringent requirements for heat resistance, UV resistance, and wear resistance demanded by automotive components.

Huashuo offers complimentary color matching services and provides customized color masterbatch solutions tailored to customer requirements. Contact our technical team for assistance.

Headlight covers

Headlight covers Interior trim panels

Interior trim panels Grille radiator

Grille radiator Bumpers

Bumpers

color masterbatch for automotive industry Solutions

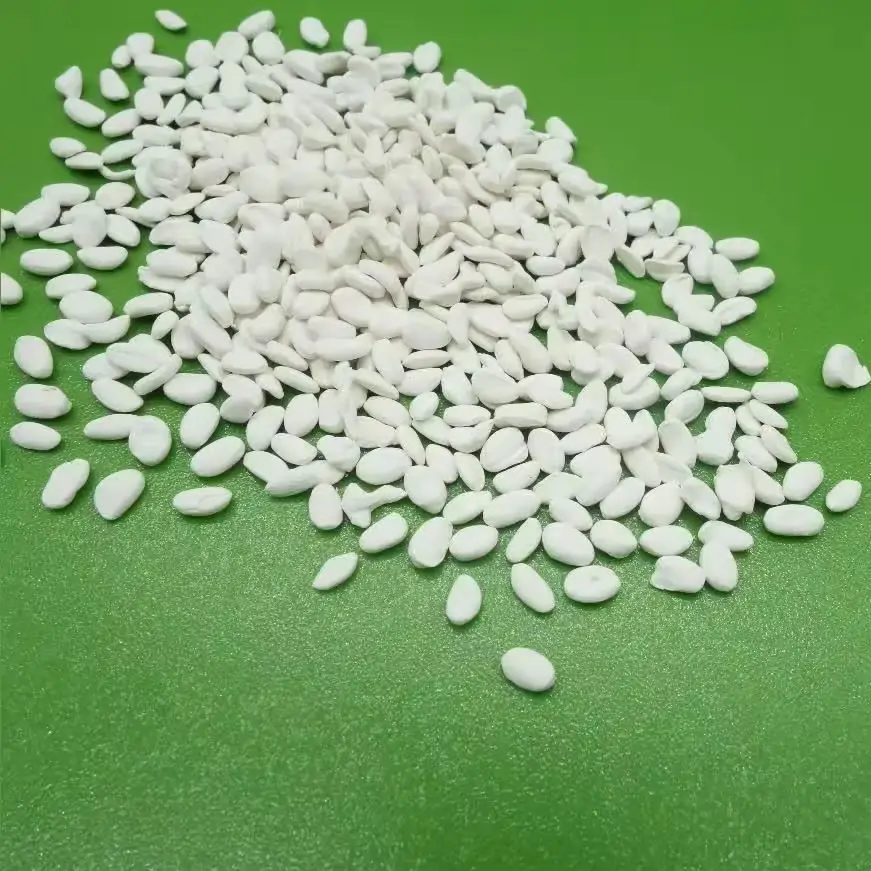

Color masterbatches are primarily used in plastic processing techniques such as injection molding, blow molding, extrusion, and hot pressing within the automotive industry. They provide precise coloring and functional modification for automotive components, ensuring consistent appearance and performance. Available color masterbatch solutions include:

- Standard color masterbatches: Deliver stable, uniform color effects for automotive exterior and interior parts.

- Functional masterbatches: Incorporate additives like UV resistance, flame retardancy, antistatic properties, or anti-aging agents to enhance component durability and safety.

- Transparent/semi-transparent masterbatches: Used for optical components such as headlight covers and trim strips to achieve ideal light transmission and color consistency.

- High-Temperature/Chemical-Resistant Masterbatches: Suitable for components exposed to high temperatures or chemical liquids, such as engine covers, battery housings, and fuel lines.

- Custom Color Masterbatches: Tailored solutions offering exclusive colors and functionalities based on client brand or vehicle model specifications.

Huashuo offers complimentary color matching services to develop customized masterbatch solutions perfectly suited to diverse automotive component requirements. Contact us today to initiate an inquiry and access our professional customization services.

Looking for Color Maching solutions?

Huashuo has experienced experts and professional equipment ready to provide you with color matching support. Click the button below now to contact our professional team.

Uses In Automotive Industry

Exterior Component Coloring: Precise coloring for automotive body panels, bumpers, mirror housings, and other exterior components, ensuring stable color and uniform gloss to enhance overall vehicle appearance quality.

Interior Component Modification: Applied to interior plastics such as dashboards, center consoles, door panels, and seat trim to improve scratch resistance, wear resistance, and surface texture.

Functional Enhancement: Incorporates functional masterbatches—UV-resistant, anti-aging, flame-retardant, or anti-static—to prolong component lifespan and safety under prolonged sun exposure, friction, or high-temperature conditions.

Luminaire and Transparent Component Applications: Used in headlight housings, signal lights, decorative trim, and other transparent/semi-transparent parts to achieve unified optical transparency and color coordination.

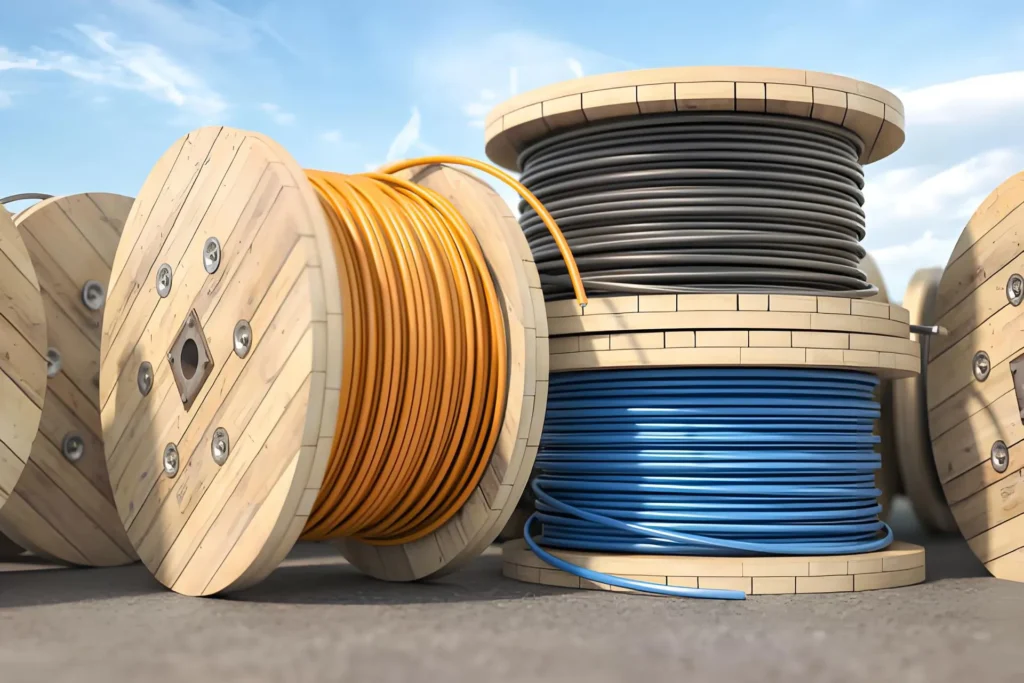

Electric Vehicle and New Energy Component Applications: Used in plastic components such as battery casings, charging connectors, and cable sheaths to provide excellent insulation and heat resistance. Custom color masterbatches enable brand identification and safety warning color schemes.

Color Masterbatches Advantages in Automotive Industry

Color masterbatches enable precise coloring of plastic components in the automotive industry. They also enhance product durability, safety, and environmental performance through functional modifications, providing high-quality material solutions for automotive manufacturing.

High Weather Resistance and Stability

Maintains color integrity and prevents deformation under high temperatures, intense sunlight, and prolonged use, meeting automotive exterior component requirements for weather resistance.

Excellent Dispersibility

olor masterbatch distributes uniformly within resin, ensuring consistent product coloration without color variation or color spots.

Functional versatility

Functional additives such as UV resistance, flame retardancy, antistatic properties, and anti-aging agents can be incorporated as needed to enhance the overall performance of automotive components.

Environmental sustainability

Formulated with non-toxic, low-VOC ingredients, compliant with automotive industry environmental standards (e.g., RoHS, REACH), supporting green manufacturing and recyclability.