Black masterbatch is a functional plastic coloring material that uses high-concentration carbon black as pigment, uniformly dispersed within a thermoplastic resin carrier through specialized processes. Its key lies in achieving a balance between pigment dispersion, processing flowability, and product performance through precise formulation design.

Compared to direct coloring with traditional color powders, it avoids issues like pigment scattering contamination and uneven coloring while significantly boosting production efficiency and reducing costs. Widely used in food packaging, electronic enclosures, automotive components, construction piping, and other fields, carbon black masterbatch enjoys widespread popularity in the plastics industry. Let’s further explore its characteristics and application areas!

The Feature of black masterbatch

Black colour masterbatch has many characteristics, let’s take a look at it together.

- Uniform coloring and high blackness: The carbon black is uniform dispersed and highly concentrated, resulting in a brilliant black finish for the product.

- High hiding power: Effectively conceals raw material color and surface imperfections.

- Improves raw material utilization: Reduces raw material waste, improves product yield, and reduces overall costs.

- High light and weather resistance: Carbon black along with added antioxidants and stabilizers, effectively delays the oxidation degradation process, making it suitable for long-term outdoor use.

- Environmentally friendly and non-toxic: Complies with environmental regulations and safety standards, suitable for fields such as food packaging and children’s products.

Black master batch has the above Various advantages, so what are its application areas?

What are the fields of black masterbatch

Black masterbatch has a wide range of applications and is commonly used in packaging materials, household appliances, automotive components, wires and cables, and other fields.

Plastic Packaging

Polyethylene (PE) offers high gloss and exceptional light-blocking properties, effectively shielding contents from ultraviolet and visible light exposure to prevent product degradation. PE carbon black colour masterbatch is widely used in packaging materials such as cosmetic containers, electronic product packaging, and light-sensitive containers.

black masterbatch for Plastic Packaging

black masterbatch for Plastic Packaging

black masterbatch for automotive components

black masterbatch for automotive components

Automotive Components

PP carbon black masterbatch has excellent UV resistance, color stability, and weather durability, while meeting high-performance requirements for strength and heat resistance. It is is widely used in automotive interior and exterior components such as bumpers and dashboards.

Home Appliances

ABS black master batch enhances surface aesthetics with its high gloss, impact resistance, thermal stability, and stain resistance, concealing substrate imperfections while extending product lifespan by delaying material aging. It is an ideal choice for appliance housings such as televisions, computers, and refrigerators.

black masterbatch for home appliances

black masterbatch for home appliances

black masterbatch for wires and cables

black masterbatch for wires and cables

Wires and Cables

PE black color masterbatch, with its outstanding UV resistance, tensile strength, and chemical stability, effectively protects cables from abrasion, fading, and chalking during prolonged outdoor exposure. It is widely used in the production of cable insulation layers and jackets.

Textile Fibers

PET carbon black color masterbatch offers outstanding lightfastness, washfastness, and coverage, while contributing to sustainable production by reducing water and energy consumption. It is commonly used in textile fiber manufacturing, such as apparel, luggage, and automotive fabrics.

black masterbatch for textile fibers

black masterbatch for textile fibers

Black masterbatch has a wide range of applications, not only in packaging, home appliances, and automotive fields, but also in construction, pipelines, agriculture, and more. It is loved by many plastics manufacturers and the public. So how do you choose black colour masterbatch based on your needs?

How to choose carbon black masterbatch

Black color masterbatch is a commonly used colorant in plastic products. Its quality affects product appearance, processing efficiency, and performance stability. When selecting carbon black masterbatch, plastics manufacturers should consider the characteristics of the masterbatch and the supplier’s service.

Key Considerations for Black Masterbatch Selection

Carbon Black Content:recommend selecting black color masterbatch with a carbon black content of 30% to 50%. This provides strong coloring, reduces additive dosage, and meets the requirements of conventional processes .

Dispersion Uniformity:high-quality carbon black colour masterbatch should ensure uniform dispersion of carbon black particles, minimizing issues such as bright spots and color spots in the finished product.

Carrier Resin Compatibility: select carrier resin (such as PE, PP, ABS, PS, etc.) that is compatible with the main material to enhance processing smoothness and avoid issues such as delamination and flow marks.

Processing Compatibility: select high-temperature-resistant, non-volatile black master batch suitable for injection molding, extrusion, blow molding, and other processes.

Key Points for Supplier Selection

Customized Services : suppliers offering customized services can meet special needs (such as functional master batches with UV protection and anti-static properties).

Quality Assurance : suppliers with international quality and environmental certifications guarantee masterbatch quality, preventing quality issues from impacting production.

After-Sales Service : suppliers offering comprehensive after-sales service can promptly resolve production issues and maintain long-term partnerships.

Value for Money : select suppliers with high delivery efficiency and good value for money to reduce time and costs while guarantee quality.

There are many factors that go into choosing the right black color masterbatch, and it requires a comprehensive assessment of product characteristics and supplier services.

Conclusion

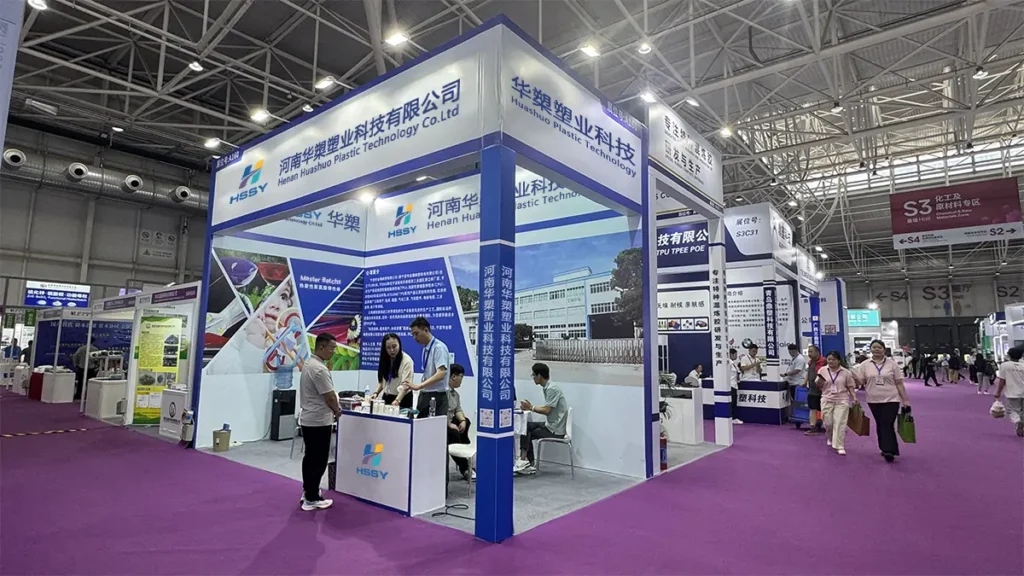

Through this introduction, we believe you’ve gained a brief understanding of the applications of black masterbatch and how to choose it. If you are a manufacturer in the plastics industry and are struggling with uneven product coloring, please contact us today. Huashuo manufacturer specializes in the production of various masterbatches. With a dedicated service team, we are committed to providing expert solutions to your production needs.