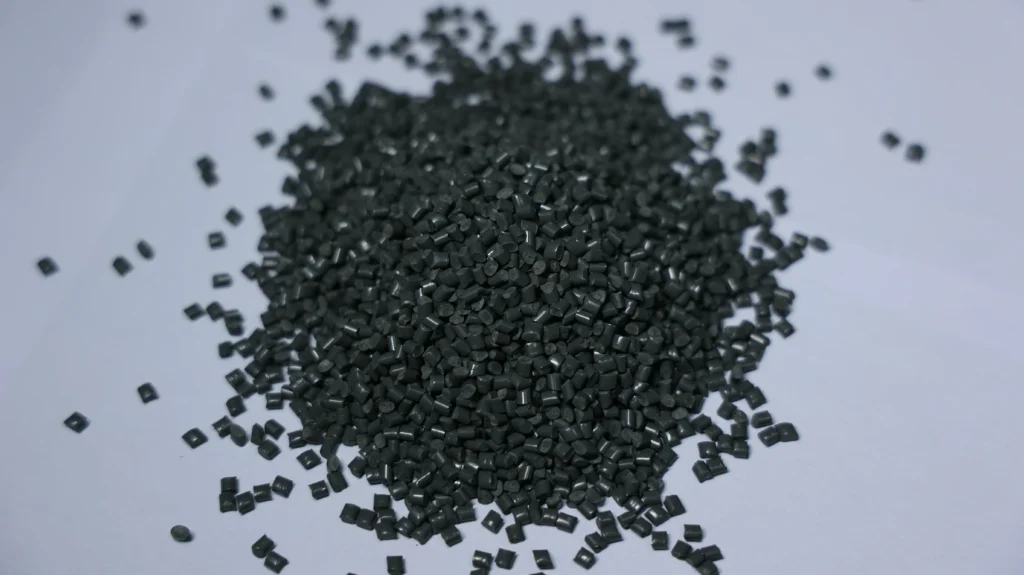

Carbon black masterbatch possesses outstanding colouring power and dispersibility, making it a commonly used colourant in plastic product manufacturing. However, many purchasers often prioritise price over the distinct characteristics of different masterbatch types during selection.

Variations in dispersibility, weather resistance, processing adaptability, and long-term stability exist across different carbon black master batch types. When procuring black masterbatches, it is essential to systematically understand the types of black masterbatches and their corresponding application scenarios, taking care to avoid selection pitfalls, minimise trial-and-error costs, and optimise procurement efficiency.

Types of Carbon Black Masterbatch

Carbon black masterbatches can typically be categorised across three dimensions: blackness difference, functional properties, and resin carrier. Below, we explore the types of black colour masterbatches.

Blackness Grades and Applications of Carbon Black Masterbatch

| Basic black colouring | Blackness | Dispersion Requirement | Cost | Typical Applications |

|---|---|---|---|---|

| High Blackness Carbon Black Masterbatch | High blackness, deep appearance | High | Relatively high | Automotive exterior parts, high-end injection molded products |

| Medium Blackness Carbon Black Color Masterbatch | Balanced blackness and performance | Medium | Medium | Home appliance housings, general injection molded products |

| Standard Blackness Carbon Black Colour Masterbatch | Basic black coloring | Low | Low | Industrial structural parts, daily-use products |

- High-blackness masterbatches are used in products requiring premium aesthetics and deep colour intensity. They deliver pure black expression but demand sophisticated dispersion systems and production processes, resulting in higher overall costs.

- Medium-blackness masterbatches offer a favourable balance between blackness, processing adaptability, and cost, making them the choice for most plastics manufacturers.

- Standard carbon black master batches satisfy basic colouring needs, suitable for plastic products where appearance quality is less critical but cost control is paramount.

Once the blackness grade is determined, functional properties must also be considered during selection.

Functional Performance Classification of Carbon Black Masterbatches

| Type | Main Function | Performance Characteristics | Typical Applications |

|---|---|---|---|

| Standard Coloring | Coloring | Stable blackness | Packaging, daily-use products |

| UV Resistant / Weatherable | Anti-aging | UV absorption | Pipes, outdoor products |

| Conductive / Antistatic | Electrical resistance control | High dispersion requirement | Cables, electronic packaging |

- Standard black masterbatches fulfil basic colouring requirements, suitable for indoor products or items without functional specifications.

- UV-resistant/weatherproof masterbatches prioritise UV absorption, delaying ageing in outdoor plastic applications such as pipes and municipal infrastructure.

- Conductive/antistatic masterbatches are employed in products or scenarios demanding surface resistance control, requiring stringent carbon black and dispersion management.

After understanding the blackness and functionality of masterbatches, note that the resin carrier used in carbon black colour masterbatches must exhibit good compatibility with the final product.

Carbon Black Masterbatch Resin Carrier Selection

| Resin Carrier | Processing Characteristics | Suitable Processes | Typical Applications |

|---|---|---|---|

| PE Carbon Black Masterbatch | Good flowability | Extrusion, blown film | Films, pipes |

| PP Carbon Black Master batch | Stable molding | Injection molding, extrusion | Home appliance housings |

| Engineering Plastic Carrier | High heat resistance | Injection moulding, extrusion | Automotive, electronics |

- PE black masterbatch suits extrusion and film blowing processes, widely used in film and pipe products.

- PP black masterbatch performs stably in injection moulding, commonly employed for appliance casings and similar items.

- Regarding engineering plastics like ABS, PET, and PS, processing demands high temperature control. Without a compatible carrier, issues such as poor dispersion or unstable performance often arise.

Carbon black colour master batch types must be highly matched to application scenarios; excessive blackness or functional properties incur unnecessary costs.

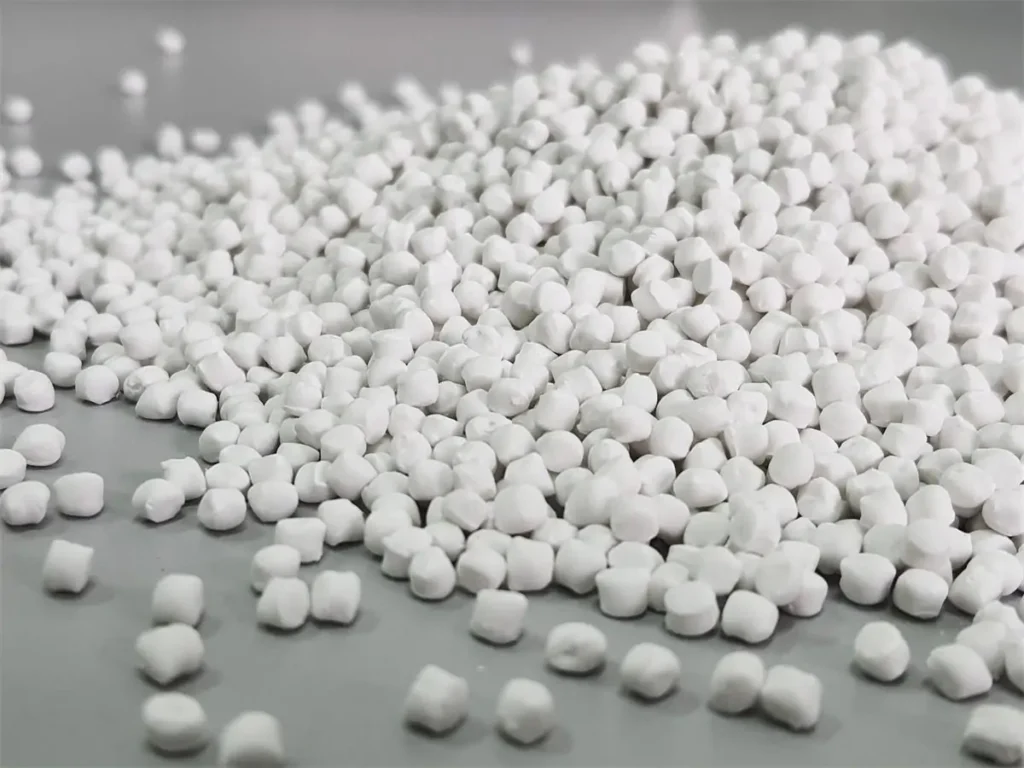

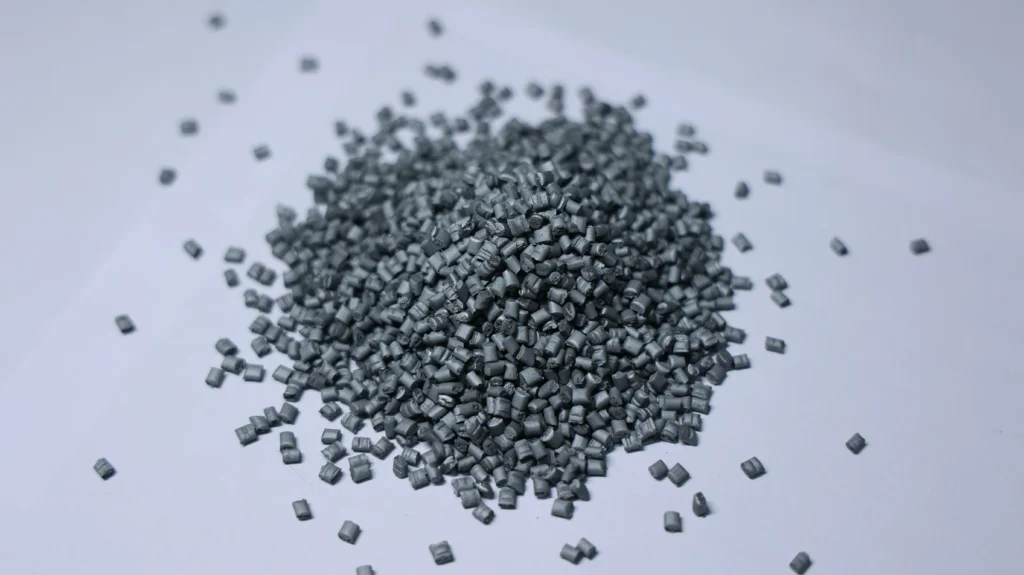

Carbon Black Masterbatch

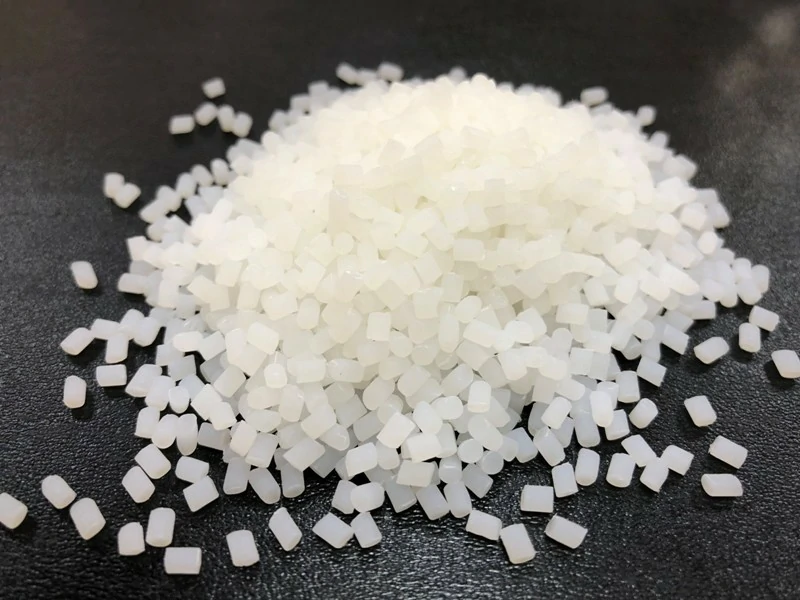

Carbon Black Masterbatch PP Carbon Black Masterbatch

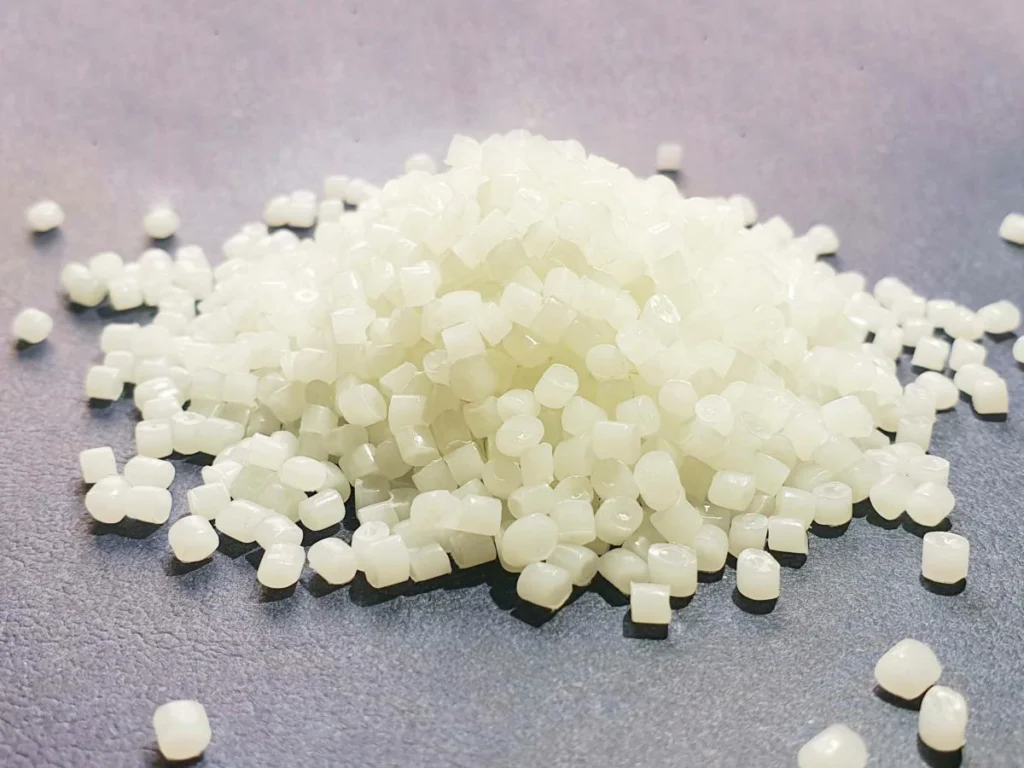

PP Carbon Black Masterbatch PE Carbon Black Masterbatch

PE Carbon Black Masterbatch

Next, we address common issues and misconceptions in procurement selection to reduce trial-and-error risks.

Common Issues in Carbon Black Masterbatch Selection

During actual procurement, the following factors frequently impact masterbatch selection:

Operating Environment: Is the product intended for outdoor use or prolonged exposure to high-ageing conditions?

Aesthetic Requirements: Are there explicit standards for blackness and colour consistency in the finished product?

Resin and Process: Are the resin type and processing method compatible with the selected carbon black master batch?

Procurement Cycle: Is this a short-term order or does it require a long-term, stable supply?

Common Procurement Pitfalls:

- Focusing solely on price while overlooking differences in masterbatch types

- Substituting functional products with standard black masterbatches results in substandard performance

- Relying solely on initial sample performance while disregarding long-term batch consistency

Acknowledging these issues ensures stability in mass production and product quality. Furthermore, purchasers should select masterbatch suppliers with professional support capabilities.

Carbon Black Masterbatch Suppliers

Masterbatch suppliers serve as material providers while also ensuring selection and stability. Suppliers with R&D and customisation capabilities can assist buyers in making more informed trade-offs between performance and cost across diverse application scenarios.

Huashuo is a specialist masterbatch supplier dedicated to masterbatch R&D and production. We offer black masterbatch solutions across multiple blackness grades, functional types, and resin carriers, suitable for injection moulding, extrusion, film blowing, and other processes. We support long-term stable supply and bespoke services.

Conclusion

This article has outlined carbon black masterbatch types, common issues, and supplier considerations. Selecting the appropriate masterbatch type and supplier is crucial. Should you require guidance on masterbatch selection, please contact us for optimal solutions.