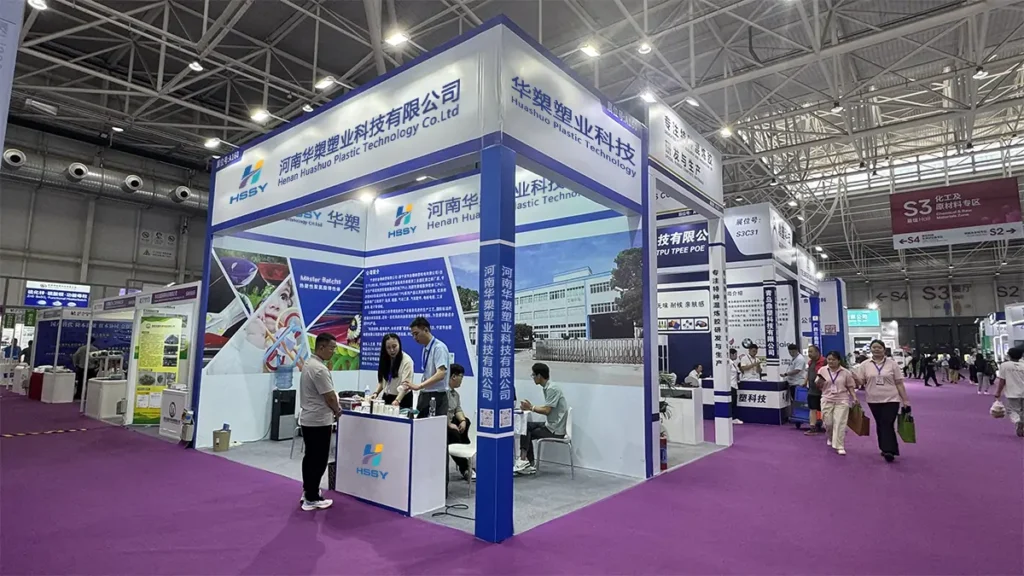

China Color Plastic Masterbatch Manufacturer

Huashuo Plastic Technology, located in Xinxiang, China, has been deeply involved in the plastics industry for over 10 years. In 2025, it integrated Shengpeng New Materials and Shengbo Mold, optimizing its production system to become a company with end-to-end smart manufacturing capabilities across the entire plastic industry chain, from raw materials to finished products. The company specializes in the research, development, and production of color masterbatches, as well as the manufacturing of injection molds and injection-molded products. It offers customized solutions, providing personalized support from product concept to full-process delivery, making it a trusted manufacturer with one-stop plastic product solutions capabilities.

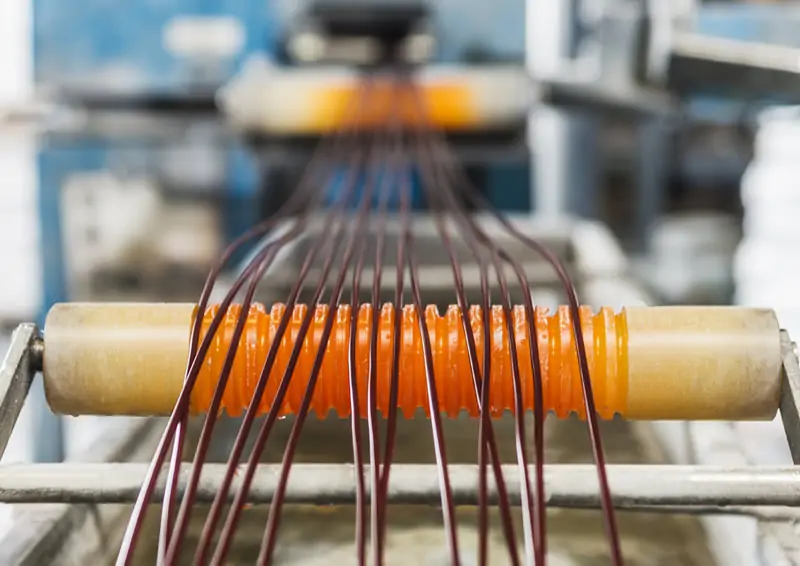

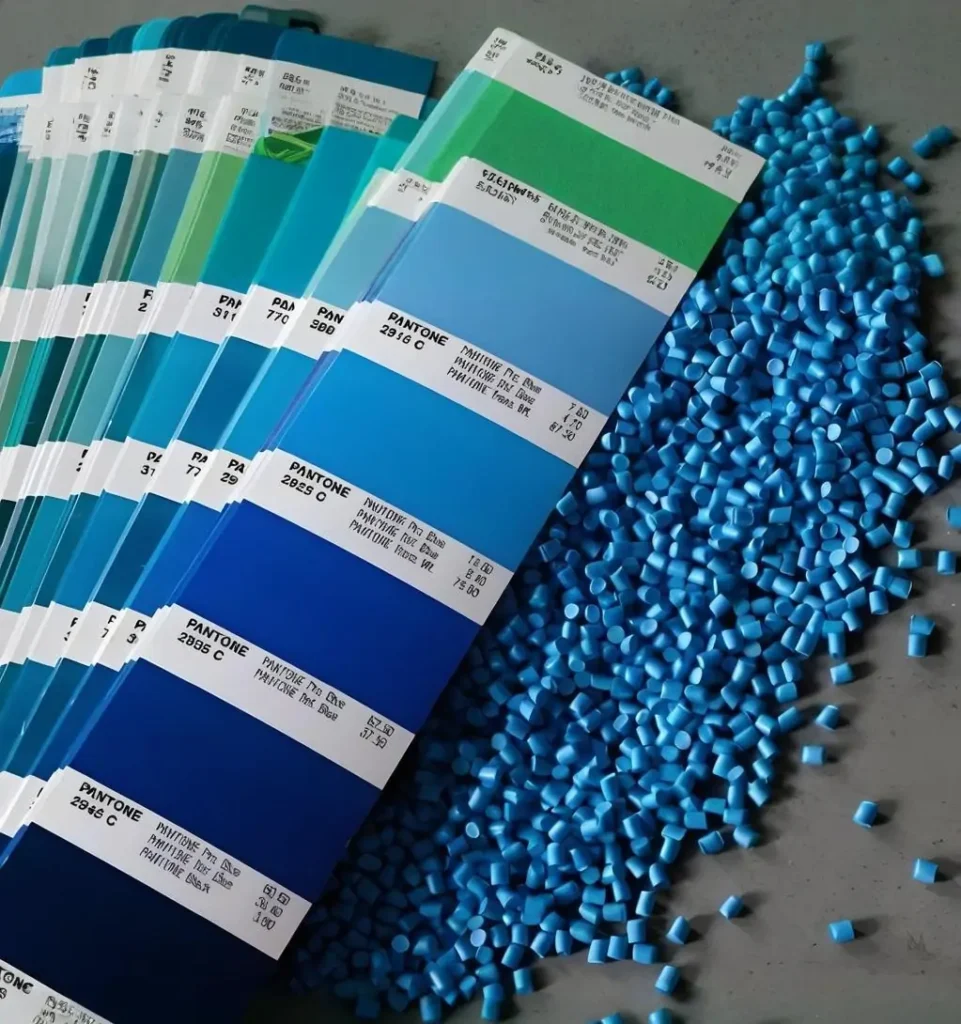

Color Masterbatch Field: Huashuo Plastic Technology is recognized as an expert in functional masterbatches, having obtained ISO 9001 international certification, with products compliant with global market regulations. With our precision color matching laboratory and efficient dispersion technology, we offer: extremely high color consistency (precisely matching international standards such as Pantone and RAL), high-performance functional masterbatches (UV resistance, flame retardancy, anti-static, slip, biodegradability, etc.), and meet customer requirements for strength, weather resistance, food safety, and environmental compliance. Our excellent dispersion and processing stability ensure enhanced production efficiency and product quality for our customers. The company operates 16 production lines of domestic and international brand parallel twin-screw pelletizing machines, along with experimental equipment including: electronic balances, electronic scales, tensile testers, cantilever beam impact testers, melt indexers, ovens, color matching light boxes, UV aging test chambers, density testers, ash content determination muffle furnaces, haze meters, light transmittance testers, color difference meters, injection molding testing machines, and experimental film blowing machines. Our robust manufacturing capabilities and high production capacity ensure that every order is delivered on time and to the highest quality standards;

ABS Color Masterbatch Manufacturer in China

Huashuo Plastic Technology understands the characteristics and application challenges of ABS materials, making us your reliable partner for ABS color masterbatches. Our ABS-specific color masterbatches:

Vibrant and long-lasting colors: Excellent compatibility with ABS base materials, uniform dispersion, high surface gloss of finished products, vibrant and vivid colors, no floating fibers or color differences.

Heat resistance and anti-yellowing: Specially formulated to withstand ABS processing temperatures, effectively preventing color degradation or yellowing caused by high temperatures, ensuring long-term stability of product appearance.

Strict consistency control: Precise color matching process ensures high color consistency between batches, meeting the strict color accuracy requirements of home appliances, electronic appliance housings, automotive interior parts, toys, and other applications.

Flexible functional integration: Can be customized to integrate UV resistance (fade prevention), flame retardancy (compliant with UL94 standards), impact resistance, and other functions to enhance the overall performance of ABS products.

With rigorous matching tests in our precision laboratory and efficient production capabilities, we ensure that every ABS color masterbatch granule helps you produce end products with exquisite appearance and outstanding performance.

China Injection Color Masterbatch Manufacturer

Huashuo Plastic Technology specializes in the research, development, and production of color masterbatches for injection molding processes, making it an ideal choice to enhance your injection molding efficiency and quality. Our injection-specific color masterbatches have distinct features:

Excellent flowability and rapid dispersion: Optimized design ensures the masterbatch disperses quickly and uniformly during high-speed injection molding, effectively preventing defects such as flow marks, weld lines, and color streaks, thereby improving yield rates.

High-temperature stability without migration: Exceptional heat resistance fully adapts to high-temperature injection molding environments, preventing pigment decomposition or migration to the product surface, ensuring pure and stable color.

Wide range of compatible base materials: Fully compatible with common injection molding plastics such as PP, PE, ABS, PS, and PC, offering precise and diverse color options.

Outstanding appearance performance: Special emphasis on product gloss, color saturation, and batch consistency, widely applied in automotive parts, appliance housings, daily consumer goods, packaging containers, and other fields.

We use dedicated injection molding testing machines for physical verification, combined with professional color matching equipment (color matching light boxes, color difference meters) to strictly control quality, ensuring that colors closely match your samples or standards. We also provide process optimization recommendations to help you achieve efficient and high-quality injection molding production.

China PP Color Masterbatch Manufacturer

As a core supplier in the polypropylene (PP) coloring field, Huashuo Plastic Technology offers a full range of high-performance PP-specific color masterbatches. Our products are widely used in packaging bags, home goods, automotive components, non-woven fabrics, and fibers:

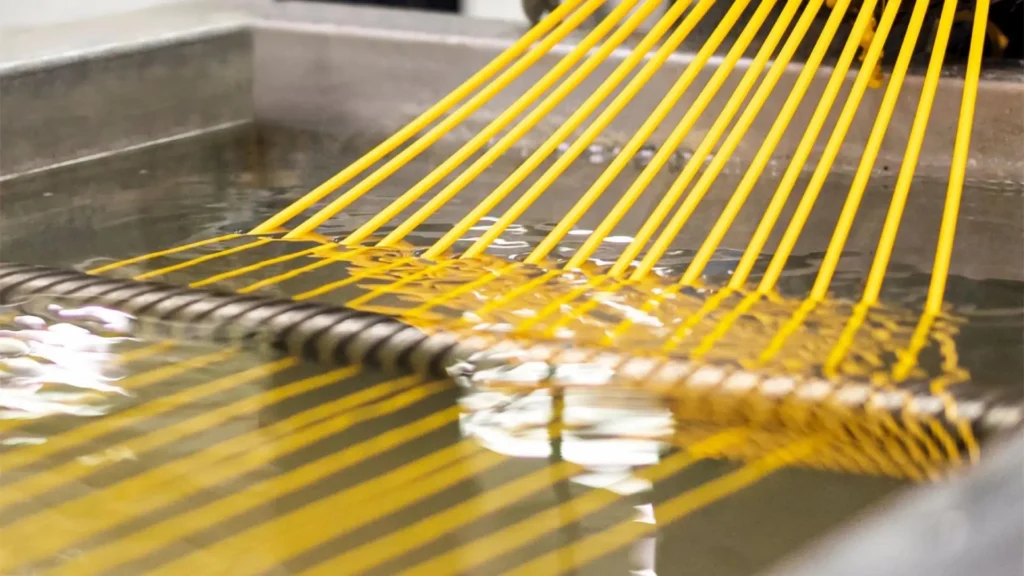

Excellent compatibility and dispersion: Perfectly integrates with PP substrates, achieving uniform dispersion in various processing methods such as film blowing, injection molding, sheet extrusion, and spinning, with no crystallization points or streaks.

Weather-resistant, UV-resistant, and color-retaining: Features a specially enhanced weather-resistant formulation that effectively resists UV radiation, slowing down fading and aging in outdoor products (such as pallets and automotive components). It also has excellent migration resistance, meeting safety requirements for food contact packaging.

Smooth processing and consistent quality: Excellent processing stability, reliable performance within the PP processing temperature range, without affecting the physical and mechanical properties of the finished product (such as impact strength and tensile strength).

Customizable functions: Can be easily integrated with functions such as slip (improving film tearability), anti-static (reducing dust adhesion), tear resistance, and flame retardancy according to application requirements, adding more value to PP products.

Backed by advanced parallel twin-screw production lines and stringent testing processes (melt index, tensile impact strength, haze, light transmittance, etc.), we ensure reliable quality and consistent batch stability of PP color masterbatches, providing you with timely and efficient supply assurance.

Conclusion

If you are also a manufacturer in the plastics industry and are suffering from headaches due to uneven coloring of your colors and products, then you can contact us now.