Organic pigments are insoluble colorants composed of carbon-containing organic compounds, characterized by vivid colors, strong tinting strength, and high transparency. They remain insoluble in media such as plastics, imparting color through particle dispersion. These high-performance coloring materials are commonly used in plastics, coatings, inks, and other fields.

Typically incorporated into plastics as organic masterbatches, these pigments enhance dispersion efficiency, minimize dust generation, and improve processing stability. They find extensive use in food packaging, cosmetic containers, daily necessities, toys, appliance housings, electronics, automotive interiors, and engineering plastic products. First, let’s explore the different types available.

Common Organic Pigment Types

Organic pigment are categorized into different types based on molecular structure and properties. Below are four common types:

Azo Pigments: Characterized by vivid colors, widely used in PP/PE low-temperature processing products.

Phthalocyanine Pigments: Exceptionally stable in blue-green hues, the most widely used organic colour in plastics.

Quinacridone Pigments: Excellent heat and light resistance, suitable for engineering plastics and outdoor products.

Perylene Pigments: Deep red hues with outstanding migration resistance and weatherability, commonly used in high-end cosmetic parts.

| Pigment Type | Primary Colors | Temperature Range (°C) | Advantages | Suitable Carriers |

|---|---|---|---|---|

| Azo | Yellow, Orange, Red | 180–240° | Vibrant colors, moderate cost | PE/PP/PVC/PS |

| Phthalocyanine | Blue, Green | 220–280° | Lightfast, heat-resistant, high cost-performance | PE/PP/PVC/PET/ABS |

| Quinacridone | Red, Magenta | 260–300° | Excellent weather resistance, migration resistance | PET/PC/PA/ABS |

| Perylene | Deep red, chestnut | 260–300° | High lightfastness, suitable for premium products | Engineering plastics, outdoor plastics |

Organic pigments come in diverse types. Select suitable pigment masterbatches based on color and plastic substrate. So, which plastics do they primarily serve? Let’s explore.

Key Applications of Organic Pigments in Plastic Coloring

Organic colour is widely used across every segment of the plastics industry, with substantial demand. Below, we explore their primary application fields.

Packaging

Main Products: PET mineral water bottles, food containers, PP/PE films, cosmetic packaging bottles, pharmaceutical packaging

Organic pigments offer vibrant colors, low migration, and environmental safety, making them suitable for food and cosmetic packaging. In PET bottles and transparent films, phthalocyanine and anthraquinone pigments deliver transparent, high-brightness colors while ensuring content safety without migration or fading.

Consumer Goods & Appliances

Main Products: Appliance housings (fans, electric kettles, rice cookers), plastic storage containers, toys, stationery, furniture accessories

Appliance housings and consumer goods require stable, high-saturation colors. Quinacridone and azo pigments are commonly used for bright, highly saturated appearances, enhancing product aesthetics and long-term durability. Additionally, they are free of heavy metals, meeting environmental compliance standards.

Automotive Applications

Main Products: Interior components (dashboards, cup holders), center console trim, buttons, functional injection-molded parts, headlight trim

The automotive industry demands high weather resistance, heat resistance, and light stability from pigments. Pyridine and quinacridone pigments within the pigment family maintain color stability under high-temperature injection molding (>260°C) and prolonged outdoor exposure, without fading, yellowing, or darkening.

Electronics & Electrical Products

Main Products: Mobile phone casings, headphones, computer casings, charger housings, wire and cable insulation layers

Electronic casings require refined aesthetic effects such as glossy finishes, transparent colors, and metallic effects. Organic pigment offers high color purity and transparency, delivering superior visual performance without compromising the electrical insulation properties of plastics.

Synthetic Fibers

Main Products: PP fibers, PET fibers, PA fibers, nonwoven fabrics, carpet yarn

Organic pigments offer high migration resistance and excellent dispersibility, maintaining stable dispersion during high-speed spinning to ensure uniform fiber coloration. Compared to traditional dyeing methods, solution coloring offers superior fade resistance and sunlight stability, making it widely used in apparel, home textiles, and related fields.

Building Materials & Outdoor Products

Main Products: PVC profiles, outdoor furniture, garden products, pipes, greenhouse films, colored sheets

Building materials and agricultural plastics demand high weather resistance and UV stability. Phthalocyanine and phthalocyanine-based organic pigments maintain color stability during prolonged outdoor exposure, resisting chalking or fading. They synergize with UV stabilizers to enhance product durability.

Having explored organic pigment applications in key plastic products, how should we select the appropriate organic masterbatch?

How to Choose the Right Organic Pigment or Masterbatch

Choosing the appropriate organic master batch requires comprehensive evaluation of material compatibility, performance requirements, and processing conditions. The following recommendations serve as a procurement or selection guide:

- Based on Resin System: Verify pigment compatibility with plastics such as PP, PE, PET, ABS, and PA, ensuring color stability and no decomposition at corresponding processing temperatures.

- By Application Field: Outdoor products require weather-resistant, UV-stable pigments like naphthalenes or quinacridones. Food packaging demands food-grade masterbatches with low migration rates. Select based on specific usage requirements.

- By Product Appearance: Transparent items need high-transparency organic colours. Products requiring high coverage should use systems with greater tinting strength or those compatible with inorganic pigment blends.

- Evaluate processing suitability: Different processes like injection molding, blow molding, extrusion, and spinning have varying requirements for heat resistance and shear resistance. Select masterbatches with excellent dispersion and high thermal stability.

- Choose reliable suppliers: Prioritize professional masterbatch suppliers who offer color matching guidance, batch consistency control, and performance test data to minimize color differences and processing issues.

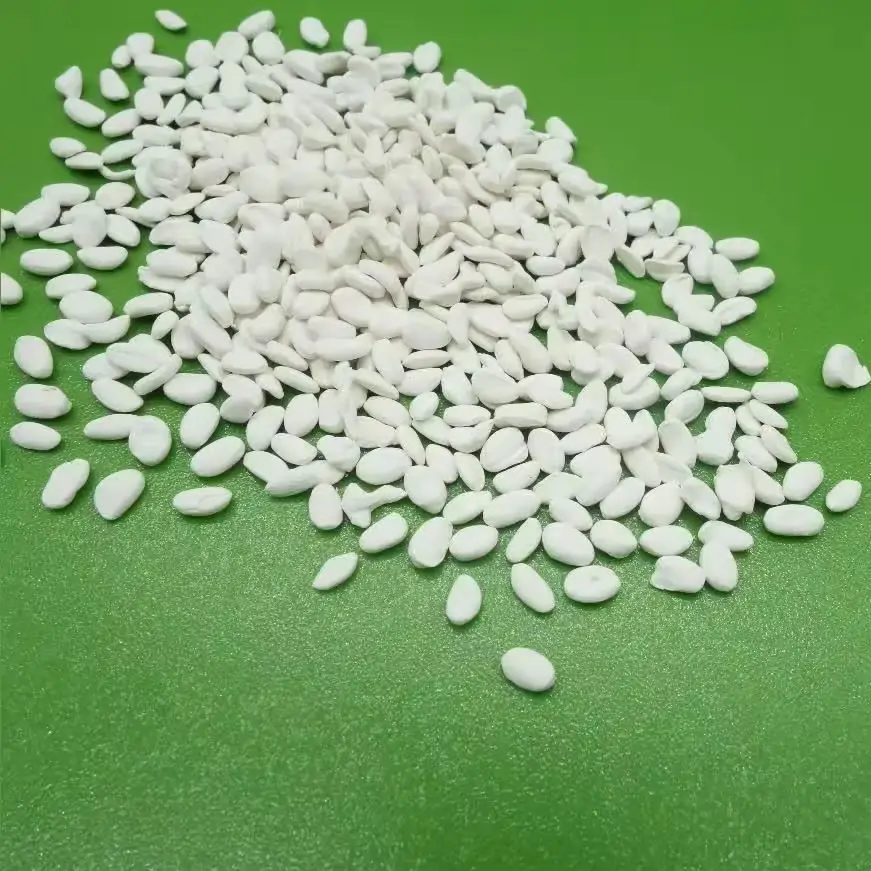

Organic Masterbatch

Organic Masterbatch Organic Pigment

Organic Pigment Organic Masterbatch

Organic Masterbatch

By considering these key points, we can more efficiently select the most suitable organic pigment masterbatches for product requirements.

Conclusion

Through this article, we have explored the types of organic pigments, their applications in plastic products, and key considerations for selecting suitable organic masterbatches. Organic colour masterbatches are extensively used in the plastics industry. If you are interested, please contact us for detailed information and tailored solutions.