Red masterbatch is a highly concentrated coloring material primarily composed of red pigments, resins, and additives. It is widely used for coloring plastic products and features excellent color stability, high-temperature resistance, and weather resistance. Compared to traditional liquid dyes, it offers simpler operation and enhanced environmental friendliness. Thanks to its outstanding performance, red color masterbatch finds extensive use in packaging, home appliances, building materials, and other sectors. Let’s explore its specific application industries.

What are the application areas of red masterbatch?

As a concentrated pellet specifically designed for plastic coloring, red color masterbatch has found extensive application across multiple sectors including packaging, automotive, and consumer goods.

Packaging Industry

- Food Packaging: Enhances color vibrancy and visual appeal, commonly used in packaging for various foods and beverages such as juices and canned goods.

- Pharmaceutical Packaging: Features UV resistance and heat tolerance, enabling packaging materials to protect medications long-term by preventing oxidation or light-induced degradation of efficacy.

red masterbatch for Plastic packaging

red masterbatch for Plastic packaging

automotive components

automotive components

Automotive Industry

- Interior Trim: Frequently used in automotive interior components such as seats, dashboards, and door trim. Coordinates with other interior color schemes to enhance overall aesthetics.

- Exterior Trim: Enhances heat and UV resistance in exterior components like red headlight housings and taillights.

Consumer Goods

- Home Appliance Housings: Televisions, refrigerators, and washing machines often utilize red masterbatch for housing coloring to enhance visual appeal.

- Daily Plastic Products: Widely used in various household and personal care items, such as plastic spoons, cups, buckets, stools, and other daily necessities.

- Children’s Toys: Red is a common color scheme for numerous children’s toys. Plastic cars, balls, and similar items feature vibrant colors and high abrasion resistance.

consumer goods

consumer goods

PVC building materials

PVC building materials

Building Materials

- PVC Pipes: Primarily used for coloring PVC pipes, enhancing both aesthetics and weather resistance. Red PVC pipes serve as visual warnings in engineering projects and are frequently used to identify fire protection and water supply pipelines.

- Flooring and Wall Decor: Applied to PVC flooring, wall panels, and other building materials to enhance aesthetics and durability while maintaining long-term color stability.

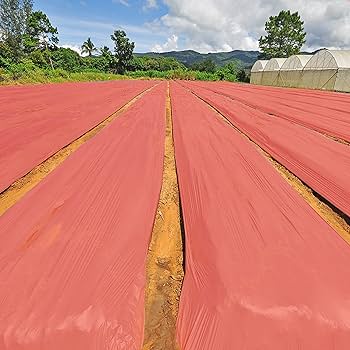

Agriculture industry

- Agricultural Films: Red films optimize plant growth environments, particularly in greenhouses and agricultural cultivation. Red masterbatch adjusts light transmittance to enhance crop lighting conditions and promote growth.

- Agricultural Tools: Used in plastic agricultural tools like flower pots, water pipes, and tillage implements, providing a vibrant appearance alongside robust durability.

agricultural film

agricultural film

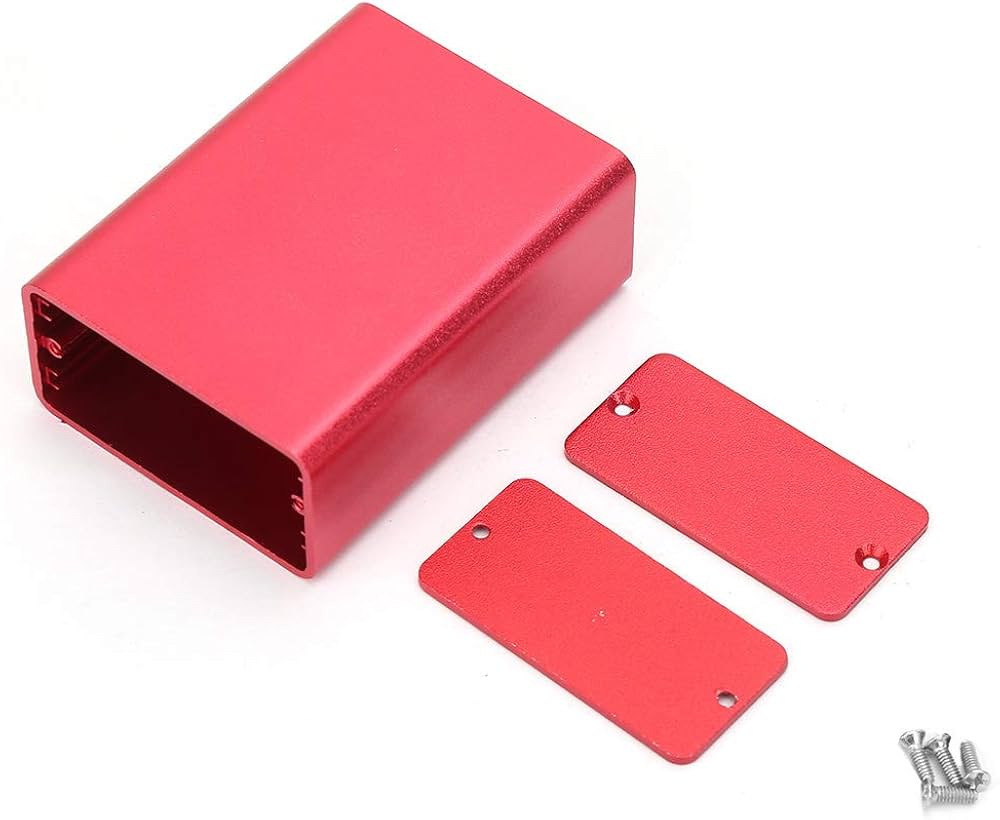

electrionic housing

electrionic housing

Electronics industry

- Phone Cases and Accessories: Numerous phone accessories, including phone cases and earphone housings, employ red masterbatch for coloring. This improves visual appeal while offering abrasion resistance and aging resistance.

- Other Electronic Device Housings: Also applied to computer accessories, power bank casings, and similar components, boosting both durability and visual appeal.

Beyond these industries, red color masterbatch finds extensive applications in medical devices, sporting goods, and other sectors. Having explored its application domains, let’s briefly examine selection criteria and market demands.

Selection Criteria and Market Demand for Red Masterbatches

As a crucial material for plastic coloring, the selection standards and market demand for red master batches directly impact product performance and competitiveness.

Selection Criteria for Red Color Masterbatches

Color Requirements: Organic red pigments offer vibrant hues and high saturation, commonly used in premium packaging and consumer goods. Inorganic red pigments provide superior heat resistance and weatherability, making them more suitable for automotive, construction, and other outdoor applications.

Physical Properties: For products exposed to high temperatures or sunlight, select red masterbatches with strong heat resistance and superior UV protection.

Environmental Compliance: Low-volatility, non-toxic masterbatches meeting international environmental standards are suitable for food packaging, medical supplies, and children’s toys.

Processing Adaptability: When selecting red colour masterbatch, ensure good compatibility with various plastic substrates (e.g., PE, PP, PVC), suitability for different processing temperatures, and consistent performance with uniform dispersion.

Market Demand Analysis for Red Color Masterbatch

High Aesthetic Appeal: As consumption upgrades, market demand for visually appealing products continues to rise. Red masterbatch, prized for its vibrant and long-lasting red hue, is widely favored in packaging, home appliances, toys, and other sectors.

High Performance: Automotive exterior components, interior parts, and lighting systems demand exceptional color stability and weather resistance, driving sustained growth in high-performance red masterbatch applications.

Customization: Market requirements for red hue, brightness, transparency, and surface effects vary significantly. Demand continues to rise for distinct color shades, gloss levels, and specialized functionalities like antistatic, flame-retardant, and UV-resistant properties.

Environmental Trends: Guided by global green manufacturing principles, demand for eco-friendly red color masterbatches is rapidly increasing. Environmental safety, harmlessness, and pollution-free properties represent key future market development directions.

Selecting red colour master batches requires balancing performance, environmental considerations, and processability. Market demand is evolving toward high performance, environmental sustainability, and customization.

FAQ about red masterbatch

Q1: What is the difference between red masterbatch and red pigment?

A1: Red masterbatch is a concentrated pellet produced by uniformly blending red pigment, resin, and additives. It offers superior dispersion and stability, along with environmental benefits and convenience. Red pigment exists as a powder that can scatter easily and result in uneven coloring.

Q2: What plastic materials are red colour masterbatches suitable for?

A2: Red color master batches can be widely used in various plastic substrates such as PE, PP, PVC, ABS, and PET. They offer excellent compatibility and dispersion, meeting the requirements of different processing techniques like injection molding, film blowing, and extrusion.

Q3: How to select the appropriate red masterbatch?

A3: Selection should comprehensively consider the usage environment (indoor or outdoor), temperature resistance requirements, UV exposure levels, and environmental standards. Organic red pigments are recommended for high-end packaging; in-organic red masterbatches are advised for construction and automotive applications to enhance weather resistance.

Q4: What are the advantages of red color masterbatch in the automotive industry?

A4: Red color master batch offers excellent high-temperature resistance and UV stability, maintaining color integrity under prolonged sunlight exposure. It is widely used in automotive interiors, exteriors, and lighting components.

Q5: Can the color and properties of red color masterbatch be customized?

A5: Yes. We can customize red hue, brightness, gloss, and functional properties (such as UV resistance, flame retardancy, and antistatic properties) according to customer requirements to achieve brand-specific color solutions.

Conclusion

Through the above discussion, we have explored the application industries and selection criteria for red color masterbatches. If you are a plastics manufacturer grappling with uneven coloring in your products, contact us today. Huashuo specializes in color masterbatch production, offering professional service teams to provide tailored solutions for your manufacturing needs.