Red masterbatch is formulated by blending red pigments, resins, and additives. As a core material for coloring plastic products, it enhances aesthetic appeal while offering color stability, mechanical properties, and long-term weather resistance.This paper explores the factors affecting the performance of red color masterbatch and optimization strategies, inviting everyone to explore it together.

Factors Affecting the Coloring Performance of Red Masterbatch

The coloring performance of red masterbatch results from the combined effects of multiple factors, including pigments, carriers, and dispersibility. Plastic manufacturers must thoroughly understand how these factors influence masterbatch to achieve high-quality coloring in plastic products.

Pigment Selection

Red masterbatch pigments are typically categorized into two types: organic reds and inorganic reds.

Organic red pigments: Examples include PR122 and PR254, which offer vibrant colors and high transparency but exhibit poor heat resistance.

Inorganic red pigments: such as iron oxide red and cadmium red, offer excellent weather resistance and thermal stability, making them suitable for outdoor and automotive applications.

The key to pigment selection lies in balancing color and performance characteristics, choosing the appropriate pigment based on specific requirements.

Resin Carrier Compatibility with Substrates

Carriers are substances that hold pigments and fully integrate with plastic substrates. Common carriers include PE, PP, PVC, ABS, PET, etc.

For red colour masterbatches used in PET or PA engineering plastics, heat-resistant carriers such as modified polyester or polyamide should be selected to prevent pigment decomposition and fading at elevated temperatures.

Significant polarity differences between the carrier and substrate can cause uneven coloring and streaking. Employing homogeneous material carriers or compatibility-modified carriers enhances the compatibility between the masterbatch and the plastic.

Dispersion Technology

Pigments are uniformly dispersed in the resin, presenting pure and saturated colors. Pigment agglomeration leads to defects such as “black spots, streaks, and bright spots” on the finished product surface. The current plastic industry employs technical optimization methods to control the dispersion of red master batch.

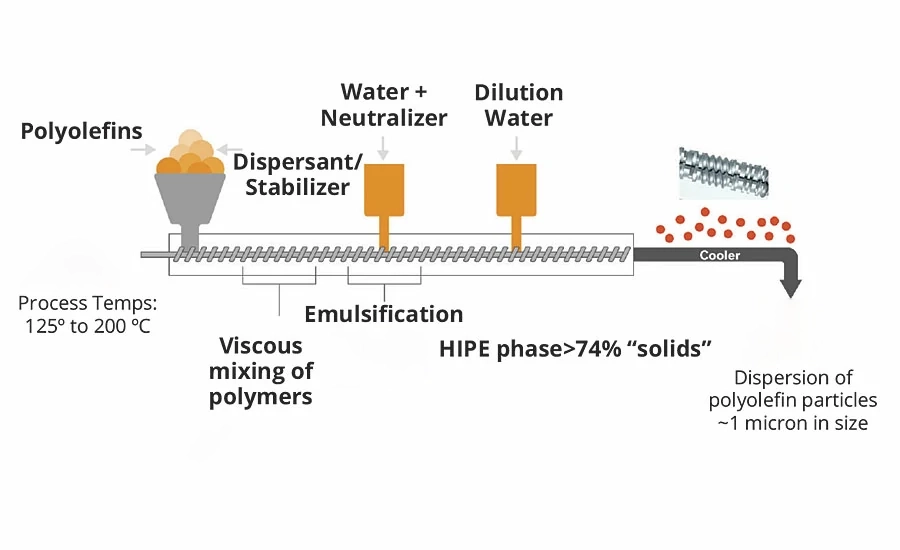

- Twin-screw compounders achieve high-shear dispersion

- Utilize surfactants or coupling agents to enhance pigment wettability

- Control pigment particle size within the 0.3-0.8 micron range through screening processes, balancing coverage and transparency

Combining these methods improves masterbatch dispersion, enhances the aesthetic appeal of plastic products, while minimizing impact on mechanical properties such as impact strength.

Processing Temperature Control

Red masterbatch exhibits different performance characteristics in injection molding, extrusion molding, and film blowing processes. Excessively high temperatures may cause pigment decomposition or carbonization, while excessively low temperatures result in incomplete dispersion, leading to surface color variations in the final product.

The safe processing temperature for organic red pigments typically does not exceed 280°C.

Iron oxide red can withstand temperatures above 400°C, making it suitable for high-temperature engineering plastics.

Pigment and carrier selection must match processing temperatures. Optimizing screw shear force and mixing time maximizes pigment performance while reducing energy consumption.

After analyzing factors affecting red masterbatch coloring performance, we will explore optimization strategies.

What are the optimization strategies for red masterbatches?

Optimization strategies for red masterbatch will shift focus from color to the system as a whole, encompassing multiple levels including formulation and carrier.

Formulation System Optimization

Pigment Blending: Combining organic and inorganic red pigments achieves dual performance of high saturation and high weather resistance. For example, in masterbatches for automotive exteriors, adding PR122 to iron oxide red base materials enhances color depth and lightfastness grades.

Functional Additive Blending: Antioxidants suppress thermal oxidation degradation, prolonging color stability. UV stabilizers enhance resistance to ultraviolet radiation. Dispersing lubricants reduce melt viscosity and improve flow properties. Through precise formulation and synergistic application of these additives, the processing stability and color uniformity of red color master batch are enhanced.

Carrier Resin Optimization

Substrate Matching Principle: Select carrier materials identical to or highly compatible with the target plastic. For instance, PP/PE carriers are used for packaging and consumer goods, ABS carriers for electronic or appliance housings, and PET/PA carriers for high-temperature engineering plastics. This enhances pigment transferability during melt fusion and improves color uniformity.

Novel Resin Carriers: Modified polyester enhances thermal stability for high-temperature processing, while bio-based polymers meet green manufacturing requirements, achieving low VOC emissions and biodegradability. Develop more functionalized, eco-friendly carriers to satisfy diverse specialized needs.

Process Equipment Optimization

High-efficiency mixing equipment (such as high-torque twin-screw extruders) is integrated with temperature control systems to guarantee product quality.

Through the implementation of intelligent temperature control technology and automated feeding systems, continuous and uniform material delivery with precise temperature management is achieved, minimizing batch-to-batch variations.

Quality Inspection and Intelligent Control

Manufacturers utilize equipment such as color difference meters, spectrophotometers, and rheometers to precisely evaluate color deviation, flow characteristics, and thermal stability.

Simultaneously, an AI-powered automatic color difference correction system automatically adjusts color formulations, enhancing the production efficiency of red masterbatch.

Optimizing red masterbatch involves multiple dimensions. Does it align with future development trends? Let’s explore.

Future Development Trends of Red Color Masterbatches

The development trajectory of red color masterbatches may evolve in several directions as consumer demands shift. Let’s explore these trends.

- High-Performance, High-Color Compounds: Flame-retardant, antimicrobial, and antistatic red masterbatches will see widespread adoption in high-value sectors like automotive, medical, and electronics.

- Environmental Sustainability: Utilizing bio-based resin carriers and low-VOC pigment systems enables biodegradable and non-toxic production. These will be extensively applied in food packaging, children’s products, and similar fields.

- Smart Manufacturing: Through intelligent manufacturing platforms, companies can achieve a closed-loop process of “automatic color matching—real-time detection—cloud-based data management,” enabling precise and efficient color control.

In short, red color masterbatch is progressively evolving toward a direction of “high performance + environmental sustainability + smart manufacturing.”

FAQ ABOUT RED MASTERBATCH

Q1: What factors primarily affect the color stability of red masterbatch?

A1: The color stability of red color masterbatch mainly depends on the pigment’s heat resistance, light resistance, dispersibility, and the compatibility between the carrier and substrate. If the pigment decomposes at high temperatures or exhibits uneven dispersion, it can lead to issues such as color variation and fading in the finished product. Selecting highly stable pigments and modified carriers can enhance color durability.

Q2: How can discoloration of red colour master batch during high-temperature processing be prevented?

A2: Match pigments and carriers appropriately based on processing conditions:

- Organic red pigments suit low-temperature plastics (e.g., PP, PE) with processing temperatures below 280°C.

- Inorganic red pigments (e.g., iron oxide red) withstand temperatures above 400°C and are suitable for engineering plastics like PA and PET.

Additionally, incorporate antioxidants and light stabilizers to enhance heat resistance and anti-aging properties.

Q3: What distinguishes eco-friendly red color masterbatches from conventional ones?

A3: Eco-friendly red masterbatches utilize low-VOC, heavy-metal-free pigment systems and bio-based carrier resins. They release no harmful substances during production or use, complying with international environmental standards like RoHS. Suitable for food packaging, medical supplies, and children’s toys.

Q4: Do different plastic systems require different red masterbatches?

A4: Yes. Different plastic substrates exhibit varying polarity and melt characteristics. For instance, PE and PP require low-polarity carriers, while PET and PA demand high-heat-resistant carriers. Selecting carriers matching the substrate enhances color uniformity and mechanical property stability.

Q5: Can red masterbatch be customized?

A5: Absolutely. Red masterbatch can be customized to meet client requirements for color shade, brightness, weather resistance grade, and processing performance.

Conclusion

Through the above article, we have gained insight into the factors influencing red masterbatch, optimization approaches, and development trends. Red masterbatch is driven not only by pigment quality and processing techniques but also by environmental trends and performance requirements.

If you are a manufacturer in the plastics industry struggling with uneven coloring in your products, contact us today. Our professional service team is ready to provide tailored solutions for your production needs.