An antimicrobial masterbatch is a functional plastic additive composed of antimicrobial agents blended with a carrier and dispersants or additives to form a functional color masterbatch. When added to conventional plastics in specific proportions, it is processed into products via standard plastic manufacturing techniques such as injection molding, extrusion, or blow molding. The resulting products exhibit antimicrobial properties, enhancing hygiene safety and extending product lifespan. Its applications in modern life are becoming increasingly widespread. Let’s take a look at the advantages of antimicrobial masterbatch.

What are the advantages of antimicrobial masterbatch?

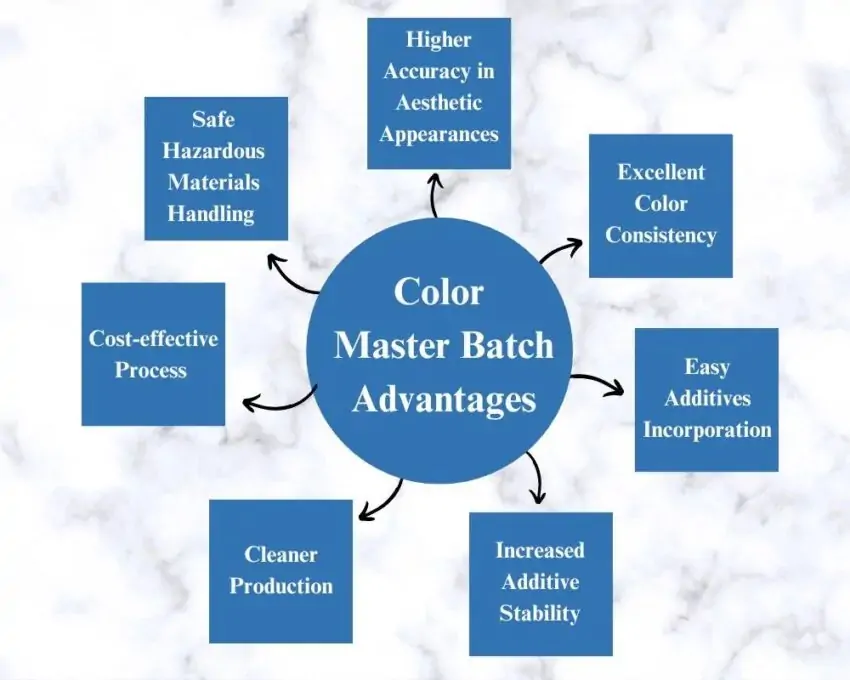

When antimicrobial masterbatch is added to ordinary plastics in specific proportions and processed using conventional methods, different products offer distinct advantages:

Enhanced hygiene and safety: This is the core advantage. Plastic products can actively inhibit or eliminate surface bacteria, mold, and other microorganisms, reducing the risk of cross-infection caused by contact and providing users with safe and hygienic products.

Extended product lifespan: The growth of mold is one of the primary causes of plastic product aging, discoloration, odor generation, and functional failure. Antimicrobial properties slow down this process, keeping the product’s appearance clean and performance stable, thereby extending its lifespan.

Easy to process: It exists in the form of masterbatch, similar to ordinary color masterbatch. It only needs to be added in proportion during plastic raw material production and can be directly formed through conventional plastic processing techniques such as injection molding, extrusion, and blow molding. This greatly simplifies the production and manufacturing of antimicrobial products.

Stable effect: The antimicrobial agent is uniformly dispersed and fixed in the plastic matrix, continuously and slowly migrating or releasing to the product surface, providing long-term antimicrobial protection. Compared to surface spraying or coating, its antimicrobial effect is more resistant to wear and washing and less prone to peeling.

Cost-effective: Compared to other antimicrobial treatment methods such as adding antimicrobial powders, the masterbatch form is easier to disperse uniformly, reduces waste, and has a simpler processing process, resulting in lower overall costs, making it advantageous for large-scale promotion and application.

Environmental friendliness: Many modern antimicrobial agents, such as silver ions, zinc ions, or organic antimicrobial agents, are relatively safe for humans and the environment at effective concentrations and comply with relevant environmental regulations.

In summary, antimicrobial masterbatch provides long-lasting antimicrobial protection for plastic products through a simple and efficient processing method, offering significant advantages in enhancing hygiene and safety, ensuring product performance, and extending service life.

The role of antimicrobial masterbatch in common fields

With its excellent performance and convenient processing properties, antimicrobial masterbatch plays an important role in many areas of modern life. Let’s take a look at its performance in various industries:

Medical and healthcare:

- Function: Prevent cross-infection and protect the safety of patients and medical staff.

- Applications: Disposable medical devices, medical packaging, bed rails, bedpans, surgical instrument handles, denture bases, protective clothing, masks, etc.

Food Packaging and Kitchenware:

- Function: Inhibits microbial growth inside packaging or on utensil surfaces, reduces the risk of food spoilage, ensures food safety, and extends food shelf life.

- Applications: Food wrap, food containers, cutting boards, tableware, refrigerator liners, water dispenser components, kitchen utensil handles, etc.

Household Goods and Appliances:

- Function: Maintain cleanliness and hygiene of frequently touched items, reduce bacterial transmission, eliminate odors, and enhance quality of life.

- Applications: Toothbrushes, combs, razors, toilet seats/covers, trash cans, washing machine drums/tubs, air conditioner vents/panels, remote controls, switch panels, phone receivers, children’s toys, etc.

Textiles and Fibers:

- Function: Enhances the long-lasting antibacterial and odor-resistant properties of fibers and fabrics, addressing issues caused by sweat-related odors and bacterial growth.

- Applications: Antimicrobial fibers are used to manufacture underwear, socks, towels, bedding, sportswear, non-woven fabrics (wet wipes, hygiene products), etc.

Public Facilities and Transportation:

- Function: Reduce the risk of bacterial transmission on high-touch surfaces (such as handrails and seats), improving public health standards.

- Applications: Bus/subway handrails and seats, elevator button panels, public seating, gym equipment handles, school desks and chairs, hotel bathroom facilities, etc.

Electronic Device Cases:

- Function: Inhibits bacterial growth on frequently touched areas (e.g., phone cases, computer keyboards/cases, mice).

- Applications: Phone cases, keyboards, mice, computer/TV cases, headphones, etc.

As can be seen, the application of antimicrobial masterbatch has penetrated various aspects closely related to people’s lives, health, and safety, providing an important material solution for building a clean and hygienic modern living environment.

Conclusion

Through the above article, we have gained an understanding of what antimicrobial masterbatch is and its applications and solutions across various industries. We are a professional masterbatch manufacturer, producing a variety of masterbatches including standard masterbatches, functional masterbatches, and custom masterbatches. If you are also seeking solutions for your production needs, please contact us immediately. We have a professional team to provide masterbatch solutions tailored to your requirements, along with a dedicated service team to assist you.