In the construction industry, color masterbatches are widely used in the production of plastic building materials such as pipes, profiles, flooring, roofing tiles, waterproof membranes, window frames, and decorative panels. Adding the appropriate amount of color masterbatch enhances the weather resistance, anti-aging properties, and surface gloss of finished products. It also improves resistance to UV radiation, humidity, and temperature fluctuations, ensuring building materials maintain stable color and performance during long-term outdoor use.

Huashuo offers complimentary color matching services and provides customized color masterbatch solutions tailored to client requirements, helping you achieve the ideal color and functional performance for architectural plastics.

PVC pipes

PVC pipes Window Frames

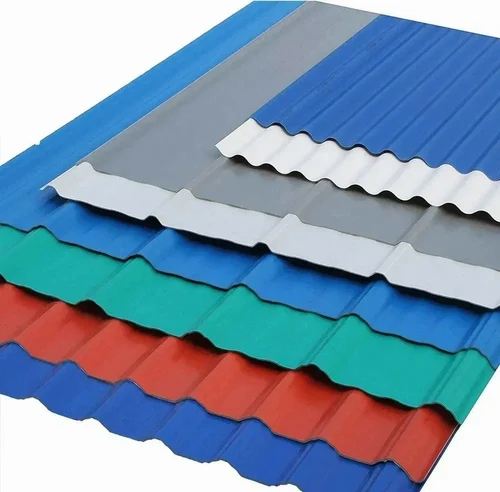

Window Frames PVC Roof Tile

PVC Roof Tile UPVC Profiles

UPVC Profiles

Color Masterbatch for Building Materials Solutions

Color masterbatches are primarily used in plastic processing techniques such as extrusion, injection molding, blow molding, and calendering within the construction industry. They provide stable coloring effects and functional modifications for various building materials, ensuring aesthetically pleasing appearances, reliable performance, and long-lasting durability. Color masterbatch solutions include:

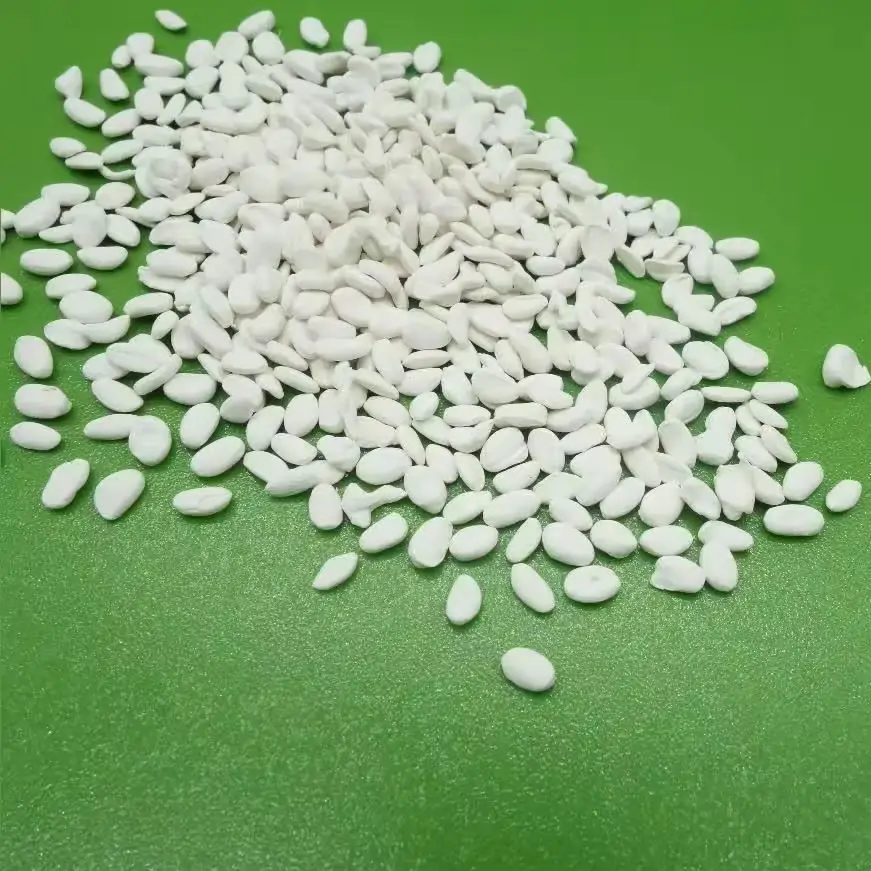

- Standard Color Masterbatches: Used in building materials like PVC pipes, profiles, flooring, and roofing tiles to achieve consistent color and uniform gloss, enhancing overall visual appeal.

- Functional Masterbatches: Incorporate functional additives like UV resistance, anti-aging agents, flame retardants, or anti-static agents to improve weather resistance and safety in building materials.

- High Weatherability Masterbatch: Specifically designed for outdoor materials, offering outstanding resistance to sunlight exposure, fading, and temperature fluctuations. Ideal for exterior wall panels, fencing, and similar applications.

- Transparent/Semi-Transparent Masterbatch: Used in translucent products like skylights, sunroofs, and decorative windows to achieve high light transmission and color harmony.

- Custom Color Masterbatches: Provide personalized color matching and performance optimization solutions based on client project requirements and brand standards.

Looking for Color Maching solutions?

Huashuo has experienced experts and professional equipment ready to provide you with color matching support. Click the button below now to contact our professional team.

Advantages of Color Masterbatches in Building Materials Industry

Color masterbatches enable precise coloring of plastic building materials in the construction sector. They also enhance product weather resistance, stability, and environmental performance through functional modification, providing high-quality color and performance assurance for building materials.

High Weather Resistance and Color Stability

Maintains vibrant hues without fading or chalking under prolonged sun exposure, rain, and temperature fluctuations, making it ideal for outdoor components like pipes, profiles, and roofing tiles.

Superior Dispersion and Processing Performance

Color masterbatch disperses uniformly within resins, ensuring consistent product coloring and smooth surfaces while improving processing flow and production efficiency.

Functional Expansion

Functional additives such as UV resistance, flame retardancy, anti-aging, anti-static, or antimicrobial agents can be incorporated to meet diverse performance requirements for building materials in various environments.

Environmental Sustainability

Formulated with non-toxic, low-VOC ingredients, these products comply with international environmental standards like RoHS and REACH, supporting the advancement of green construction and recyclable building materials.