In packaging industry production, color masterbatches are widely used in the manufacturing of roll bags, shopping bags, food packaging, and trash bags. By appropriately adding color masterbatches, the processing fluidity of plastic films can be enhanced, printability improved, and the tensile properties and puncture resistance of finished products optimized. This meets usage requirements such as tear resistance, high-temperature tolerance, and low-temperature brittleness resistance.

For food-grade packaging, the masterbatch must comply with FDA and EU standards for food contact materials to ensure safety and environmental sustainability. Certain functional masterbatches can impart UV resistance, anti-static properties, or biodegradability to packaging, meeting diverse market demands and sustainability requirements for retail packaging.

Beverage Packaging

Beverage Packaging Rolled Plastic Bags

Rolled Plastic Bags PE Food Wrap Film

PE Food Wrap Film Packaging

Packaging

Color Masterbatch Solutions

Huashuo offers a wide range of color masterbatch solutions, including commonly used types such as white masterbatch, black masterbatch, colored masterbatch, filler masterbatch, and functional masterbatches (e.g., UV-resistant masterbatch, anti-static masterbatch, and biodegradable masterbatch). These can be customized to meet your specific end-product requirements.

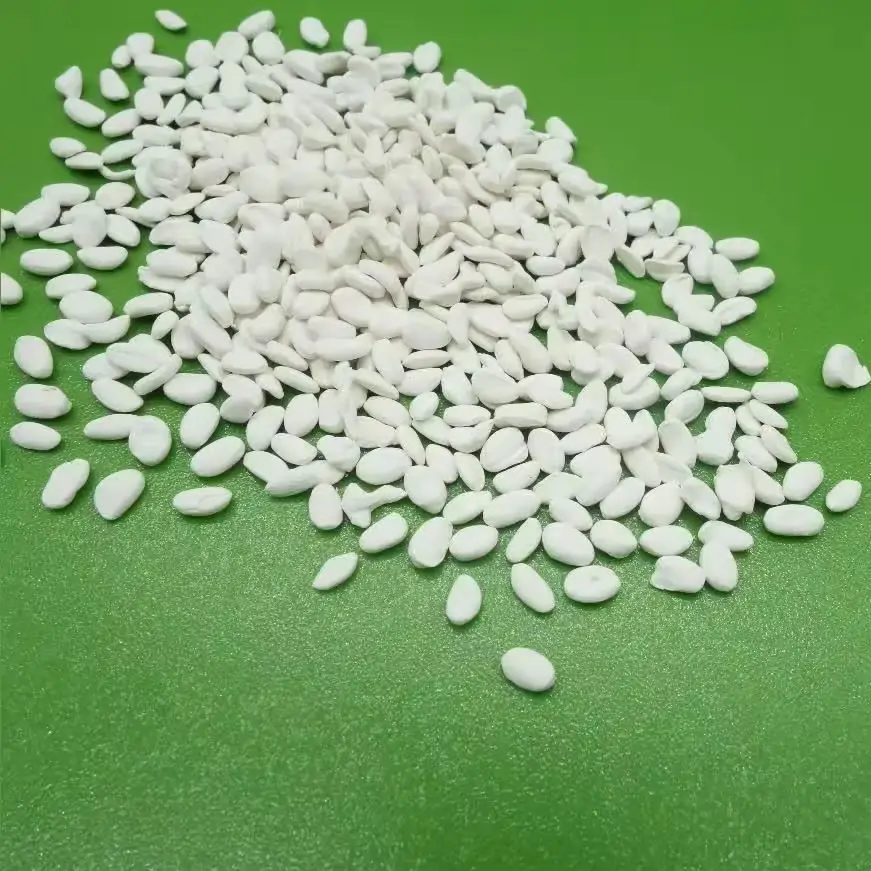

Filler Masterbatch

Filler masterbatches (such as PE fillers, transparent fillers, and bio-based fillers) are widely used in blown film applications like shopping bags, roll bags, and food packaging films. By incorporating inorganic or organic fillers into polymers, they not only reduce material costs but also enhance the mechanical properties and processability of films while meeting environmental and functional requirements.

- Reduced Production Costs: Substituting part of the polymer with filler materials saves raw material expenses.

- Improved Processing Performance: Fillers like CaCO₃ offer excellent thermal conductivity, shortening production cycles and enhancing manufacturing stability.

- Enhanced Film Properties: Increases film stiffness, impact resistance, and overall durability.

- Improved Printability: Ensures a smooth film surface with good adhesion, resulting in superior printing quality.

- Environmentally Friendly: Bio-based fillers enable partial or complete biodegradability, aligning with sustainable development requirements.

Additive Solutions

Functional additives are widely used in plastic films and packaging materials to optimize film properties, enhance production efficiency, and improve final product quality.

- Anti-blocking & Slip Agents: Prevent interlayer adhesion in films, improve product quality and boost production efficiency

- Processing Aids: Reduce equipment friction, optimize polymer flow, ensure production stability

- Anti-fog Agents: Inhibit surface condensation, enhance transparency, suitable for food packaging

- Antistatic Agents: Reduce static buildup, ensure production safety and maintain packaging integrity

- Desiccants: Absorb moisture from raw materials, effectively reduce processing defects like bubbles and fish eyes

Looking for Color Maching solutions?

Huashuo has experienced experts and professional equipment ready to provide you with color matching support. Click the button below now to contact our professional team.

Uses In packaging industry

Food and Agricultural Product Packaging: Used in flexible films and rigid containers to ensure food freshness and enhance color appeal.

Transportation and Storage Protection: Packaging films, bags, shrink wraps, and stretch wraps effectively prevent damage and contamination during transit.

Protective and Cushioning Materials: Applied in foam packaging, cardboard boxes, pallets, and drums to safeguard fragile products.

Consumer Goods and Industrial Packaging: Suitable for bottles, containers, chemical drums, and household product packaging to meet diverse market demands.

Specialized Packaging Applications: Dedicated packaging bags for horticulture, building materials, pet supplies, and animal feed, offering durability and ease of storage/handling.

Label Films: Label films for bottles and containers, enhancing product recognition.

Features in packaging industry

Precise Color Matching, achieves accurate hue alignment for consistent product appearance. Highly compatible with mainstream polymers including PE, PP, PS, PET, and ABS.

Superior Dispersion

Ensures uniform pigment distribution across plastic surfaces, preventing streaks or uneven tinting.

Lightfastness

Maintains color stability under high temperatures, exposure to light, and processing conditions.

Functional Additives

Offers options for UV resistance, anti-aging, anti-static properties, flame retardancy, and biodegradability to enhance product functionality.

Efficient Storage & Transportation

Features stable physical properties for easy handling, storage, and global logistics.