ABS Masterbatch

ABS masterbatch is a specialized color masterbatch formulated with high-purity pigments combined with dispersants and additives, using ABS resin as the carrier. It is produced through high-temperature melting, pelletization, and cooling. Its primary functions include ensuring uniform color distribution in ABS plastic products, eliminating color streaks or bands, stabilizing product performance, and streamlining the production process.

- Colors: ABS black masterbatch, white, red, blue, yellow, and other standard colors, as well as special colors such as metallic, fluorescent, and matte finishes. Custom colors can also be developed based on customer samples or Pantone color numbers.

- Dispersants: Polyolefin waxes, EBS, specialty dispersants, etc.

- Additives: Antioxidants, light stabilizers, flame retardants, antistatic agents, impact modifiers, etc.

- Suitable production processes: Injection molding, extrusion, blow molding, calendering, etc.

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmed

- Payment Terms: T/T,, L/C

aDVANTAGES

ABS color masterbatch offers excellent dispersion and tinting strength, enhancing the appearance and performance stability of plastic products.

Uniform Coloration

High-quality dispersants ensure ABS masterbatch blends seamlessly with ABS resin, preventing surface defects like color spots, streaks, or uneven tints.

Stable Performance

ABS masterbatch maintains consistent physical and chemical properties, resisting decomposition, discoloration, and degradation of mechanical properties during high-temperature processing.

Cost-Efficiency

ABS masterbatch features high pigment concentration (typically 20%-60%), reducing material usage during production. It eliminates waste from direct pigment addition, simplifies mixing processes, and lowers overall manufacturing costs.

Enhanced Surface Gloss and Aesthetics

Our ABS masterbatch utilizes highly compatible carrier resins and optimized pigment particle ratios. During ABS product processing, it fills microscopic surface pores, reduces surface defects, and improves gloss.

Environmentally Friendly & Safe

All Huashuo raw materials comply with international environmental standards (e.g., RoHS, REACH) and food contact safety standards (e.g., FDA), free from harmful substances like heavy metals and volatile organic compounds.

Convenient to Use

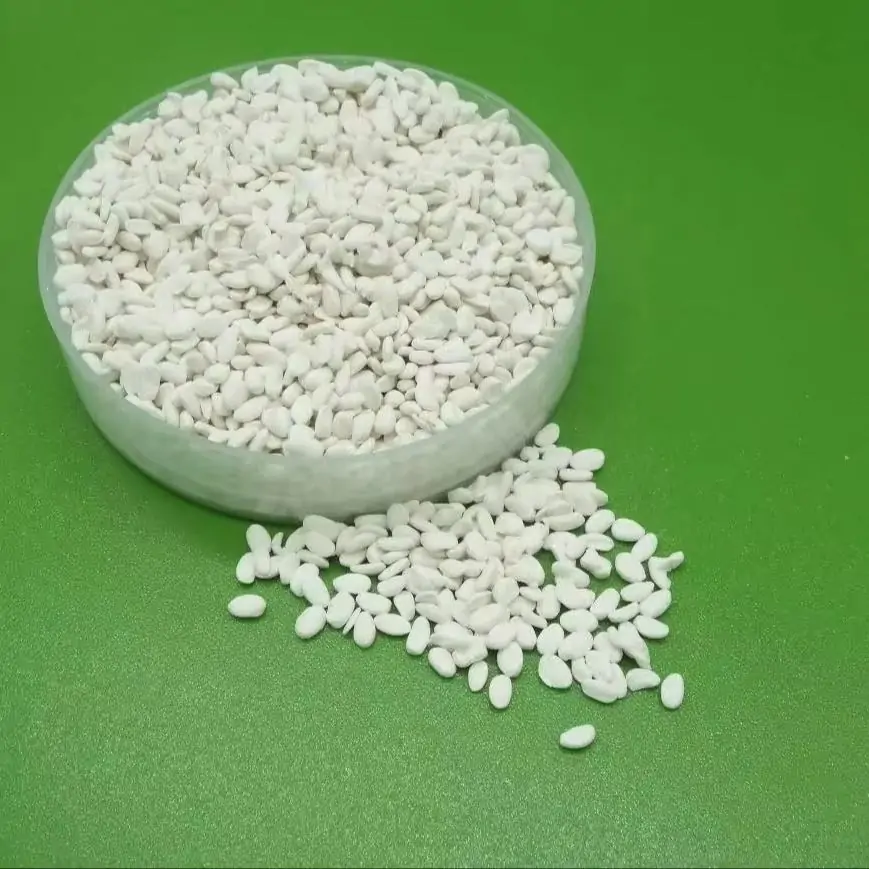

ABS masterbatch comes in granular form, facilitating transportation, storage, and blending with ABS raw material. Its use generates no dust, improving the working environment.

Specifications

| Product name | ABS flame-retardant masterbatch |

|---|---|

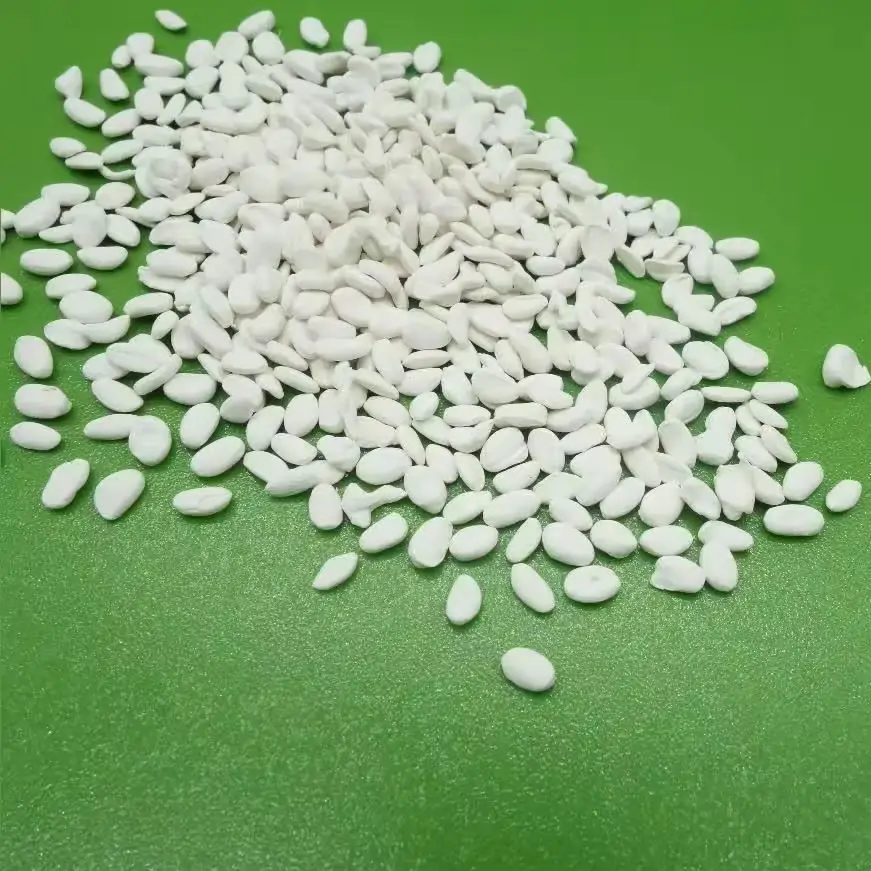

| exterior | White sheet-like shape |

| isotopic carrier | compatilizer |

| Flame retardant content (%) | ≥75 |

| Density (g/cm³) | 1.8 |

| UL94/3.2mmV0 | Add 20% to 25% |

| O Notched Izod impact | 9.1 |

| merit | The product has a high whiteness. |

Customized ABS Masterbatches

Huashuo can customize ABS color masterbatches according to your specific requirements, such as color and functional additives, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Performance requirements (heat resistance, weather resistance, impact resistance, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

“aBS Masterbatchs in Different Industries ”

”

– Our ABS masterbatch finds extensive applications across multiple industries

Plastics Manufacturing Industry

Used for coloring ABS plastic components such as appliance housings, home appliance parts, and daily-use plastic products.

Packaging Industry

Suitable for manufacturing ABS packaging products like premium packaging boxes, packaging trays, and thermoformed packaging. ABS color masterbatch delivers vibrant colors and excellent weather resistance, enhancing packaging appeal.

Toy Industry

Our ABS color masterbatch (compliant with FDA and EN 71 standards) is used to color ABS toys, providing vibrant, non-toxic colors that ensure child safety.

Pipe and Profile Industry

UV-resistant and anti-aging additives incorporated into ABS masterbatch enhance the outdoor durability of pipes and profiles, preventing fading and performance degradation caused by sunlight and environmental factors.

Automotive Industry

Used in interior panels, dashboards, and other components, they provide superior weather resistance and scratch resistance. They match vehicle colors to ensure visual consistency and durability.

Electronics and Appliances Industry

ABS color masterbatches are primarily used for components like housings and buttons, offering excellent electrical insulation and heat resistance.

PE Masterbatchs in Plastic

Packaging Trays

Packaging Trays ABS Toys

ABS Toys ABS Pipes

ABS Pipes

Automotive Industry

Automotive Industry

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.