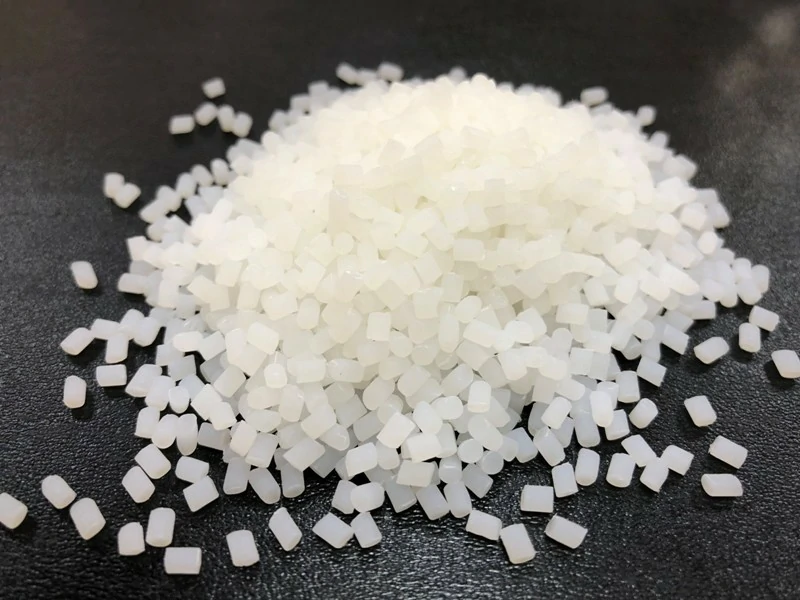

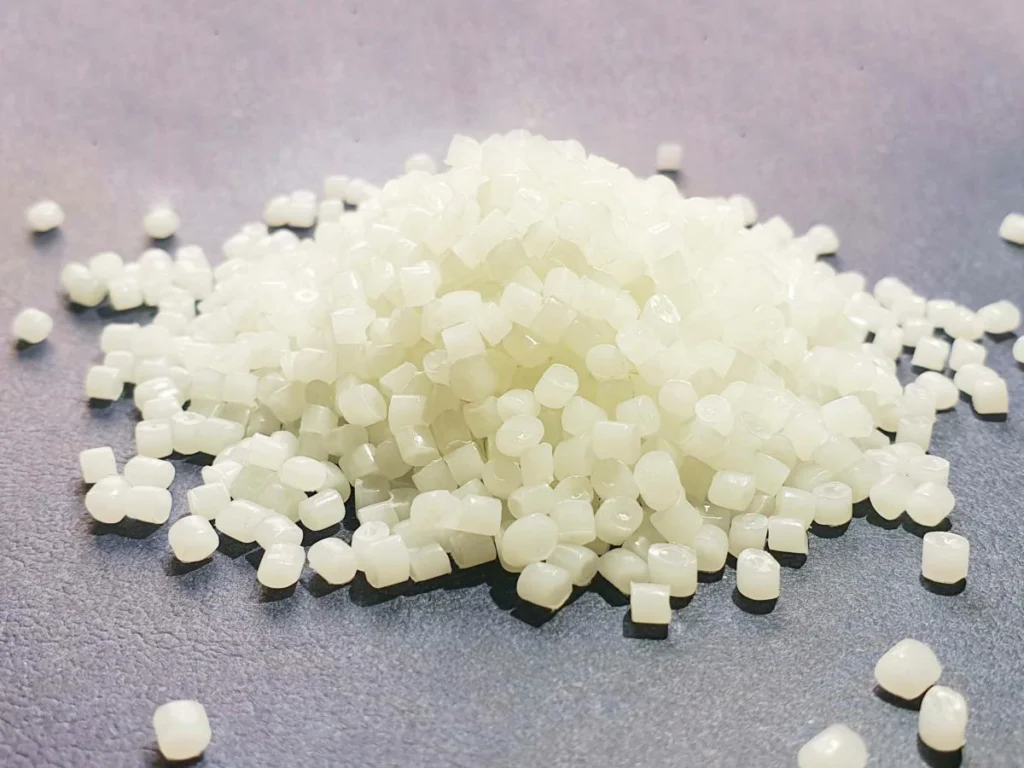

Antimicrobial masterbatch

Antimicrobial masterbatch is a functional plastic masterbatch, specifically a highly concentrated functional plastic masterbatch in which potent antimicrobial agents—such as silver ions, copper ions, or organic antimicrobial compounds—are uniformly dispersed at high concentrations within a plastic carrier. During the processing of plastic products, this highly concentrated masterbatch is uniformly incorporated into the plastic carrier, thereby imparting enduring antimicrobial properties to the finished article.

- Colour: Available in transparent, white, and custom colours from the Pantone colour chart, or by sample matching.

- Suitable Substrates: Common plastic resins including PP, PE, ABS, PS, EVA, TPE, PET, etc. Custom substrates supported.

- Dispersants: Polyethylene wax, EVA wax, modified silicone-based dispersants, etc.

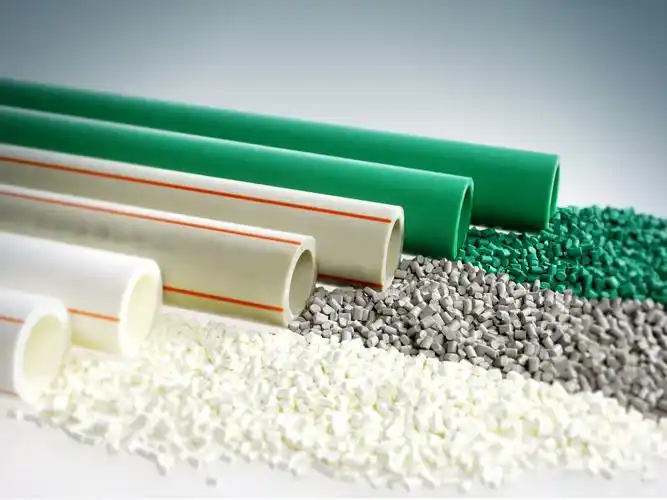

- Suitable Plastic Processing Methods: Injection moulding, extrusion moulding, blow moulding, film blowing, thermoforming, etc.

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmed

- Payment Terms: T/T,, L/C

aDVANTAGES

With antimicrobial masterbatch, your products stay cleaner, safer, and odour-free for longer.

Long-lasting Antimicrobial Efficacy

Antimicrobial masterbatch incorporates antimicrobial agents uniformly throughout the plastic matrix, ensuring both internal and external antimicrobial protection for plastic products. This prevents loss of efficacy due to friction or cleaning.

Broad-spectrum Antimicrobial Activity

Inhibits common harmful microorganisms including Escherichia coli, Staphylococcus aureus, Klebsiella pneumoniae, Aspergillus niger, and Candida albicans, complying with international antimicrobial standards such as ISO 22196 and ASTM E2149.

Convenient to Use

During the production process of plastic products, it is added to the plastic material in a specific proportion. This enables the production of plastic items with antimicrobial properties without requiring any modification to existing manufacturing processes or procedures.

Safety and Environmental Protection

The products (particularly the copper antimicrobial masterbatch) comply with RoHS, REACH, FDA, and GB 4806.7-2016 standards. They are non-toxic, non-irritating, and do not release harmful substances during use.

High Compatibility

Exhibits excellent compatibility with most base plastics such as PP, PE, PET, etc., without compromising the mechanical properties of the original plastic.

Enhancing Product Value

The incorporation of antimicrobial properties into plastic products affords them greater competitive advantage in the marketplace.

Specifications

| Product name | Antimicrobial Masterbatch |

|---|---|

| Antibacterial efficacy | ≥ 99% against Escherichia coli and Staphylococcus aureus |

| Heat resistance | 200–300°C |

| Compatibility | Common plastics such as PP, PE, and PET can all be stably compatible. |

| Particle Size | 2-5 mm |

| Moisture Content | ≤ 0.1% |

| Loading of Antimicrobial Agent | 5%–20% (customisable according to client requirements) |

Customized Antimicrobial Masterbatch

Huashuo can customize antimicrobial color masterbatches according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, ABS, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

Performance in 5 Industries

| Industry | Carrier | Loading (%) | Key Benefit |

|---|---|---|---|

| Medical Nonwoven PP | PP | 2–3% | >99.9% antibacterial, skin-friendly |

| Food Packaging HDPE | HDPE | 1.5–2.5% | FDA compliant, extends shelf life |

| Home Appliance ABS | ABS | 2–3% | Long-lasting antibacterial, durable |

| Flooring PVC | PVC | 3–4% | Anti-mold, abrasion resistant |

| Fiber Spinning PET | PET | 2–3% | Heat-resistant, washable >50 cycles |

“Types of Antimicrobial Masterbatch ”

”

A Multi-Dimensional Analysis of the Types and Applications of Antibacterial Masterbatches

Copper Antimicrobial Masterbatch

Containing copper ions as the active ingredient, it offers high safety and excellent value for money, making it suitable for food contact and medical products.

Silver-based Antimicrobial Masterbatch

The most representative inorganic antimicrobial agent, centred on silver ions, offering broad-spectrum antimicrobial activity, high efficiency, high-temperature resistance, and excellent safety. However, it carries a higher cost and is suitable for high-end electronics and medical equipment.

Zinc-based Antimicrobial Masterbatch:

Centred on zinc oxide, it exhibits excellent compatibility with plastics and is commonly used as an auxiliary component. It synergises with silver or copper to enhance performance. Suitable for daily chemical and packaging products.

Organic Antimicrobial Masterbatch

Contains organic compounds such as quaternary ammonium salts, offering rapid efficacy. However, its heat resistance and durability typically fall short of inorganic types, making it suitable for short-term applications such as disposable packaging.

Classified by Carrier Type

PP-based antimicrobial masterbatch, PE-based antimicrobial masterbatch, PET-based antimicrobial masterbatch, etc.

Classified by Application

Food-grade antibacterial masterbatch, medical-grade antibacterial masterbatch, electronic-grade antibacterial masterbatch, etc.

Antimicrobial Masterbatchs in Plastic

Antibacterial phone case

Antibacterial phone case Antibacterial Bus handrails

Antibacterial Bus handrails Antimicrobial Plastic Products

Antimicrobial Plastic Products

Antimicrobial Engineering Plastics

Antimicrobial Engineering Plastics Antimicrobial Medical Plastics

Antimicrobial Medical Plastics

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.