Blue Color Masterbatch

Blue masterbatch is a specialized colored masterbatch widely used in plastics, textiles, and various industrial applications. It provides vibrant and long-lasting blue hues while enhancing the overall performance of the final product. By incorporating blue masterbatch, manufacturers can achieve exceptional color consistency, enhanced UV resistance, and increased durability, ensuring that the product maintains its appearance and quality over time.

- Color: Blue

- Catalog No.: MB4953

- Carrier Material: PE/PP/ABS/PS/PMMA

- Melting Point: 120~280(℃)

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmed

- Payment Terms: T/T,, L/C

Advantages of Blue Masterbatch

Enhanced Visual Appeal

Provides products with vibrant and stable blue effects, enhancing color saturation and making products more competitive in the market.

Excellent UV Resistance

Effectively resists fading and aging caused by sunlight exposure, extending the service life of outdoor products.

Good Thermal Stability

Enhances high-temperature resistance, suitable for high-temperature applications such as electronic components and automotive parts.

Improved Durability

Enhances resistance to aging and weathering, ensuring products maintain color and performance stability even in harsh environments.

48-Hour Custom Color Solution

Wide Range of Applications

Widely used in plastic packaging, textiles, automotive, and appliance industries, it can also meet functional requirements such as enhancing conductivity or achieving special aesthetic effects.

Enhanced Brand Image

Blue symbolizes trust, reliability, and wisdom. Using blue masterbatch creates a professional and reliable brand perception, strengthening customer trust.

Specifications

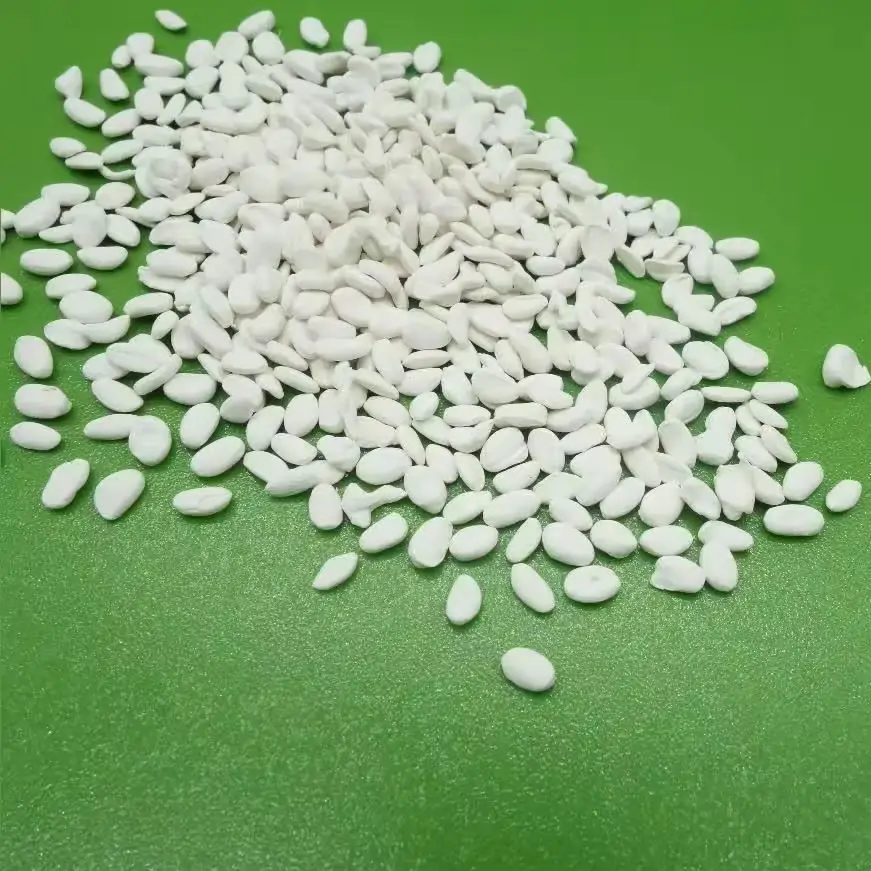

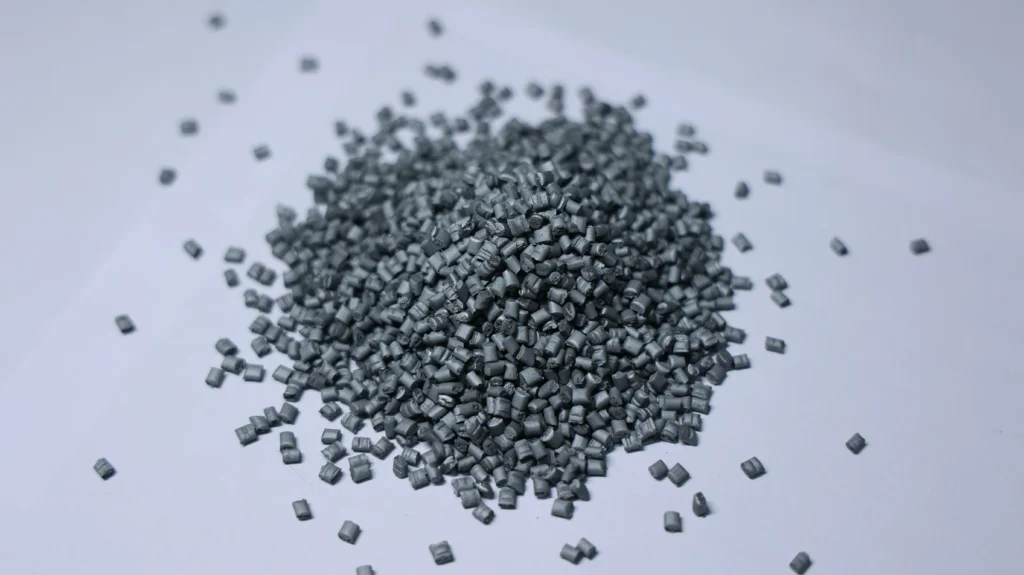

Blue masterbatch boasts excellent dispersion and processing properties, making it suitable for a variety of production processes, including injection molding, extrusion molding, blow molding, and fiber spinning. In industries such as packaging, automotive, home goods, and textiles, blue masterbatch offers a reliable and cost-effective coloring solution that combines aesthetic appeal with functional performance. Below are the parameters of blue color masterbatch:

| Carrier | PE/PP/ABS/PS/PMMA |

| Color | Blue |

| Light Resistance (Grade 1-8) | 8 |

| Heat Resistance (℃) | 1500 |

| Migration Resistance (Grade 1-5) | 5 |

| Effective Solid Content (%) | 20.0±0.2 |

| Melting Point (℃) | 120~280 |

| Intrinsic Viscosity (dL/g) | 0.50±0.05 |

| Moisture Content (%) | ≤0.02 |

| Specific Gravity | 1.7 |

Common Types of Blue Masterbatches

- Standard Blue Masterbatch: The most common and widely used type, suitable for a variety of plastic products and industrial applications.

- Metal Blue Masterbatch: Contains metal particles, giving products a shiny, reflective finish, commonly used in automotive parts and consumer electronics.

- Fluorescent Blue Masterbatch: Contains fluorescent pigments that glow under ultraviolet light, commonly used in safety vests, traffic cones, and other safety products.

- Pearlescent Blue Masterbatch: Contains pearlescent pigments, producing a pearlescent luster, widely used in cosmetic packaging and automotive decoration.

“Blue Masterbatch in Different Industries .”

.”

– used in film, extrusion, injection molding, foaming

Packaging industry: Widely used in bottles, bottle caps, and containers to give products a vibrant, clean appearance and enhance brand recognition.

Textiles and fibers: Used in the production of colored fibers and fabrics, it maintains colorfastness and fade resistance over time.

Agricultural films: Provides color differentiation and enhances UV resistance, extending the lifespan of plastic in outdoor environments.

Automotive and construction materials: Used in components, pipes, panels, etc., it offers weather resistance and aesthetic appeal.

Consumer goods: Applied to home goods, food packaging, and toys, it ensures safety and color stability.

Optimizing productivity and costs

Blue color masterbatch enhances the color vibrancy and visual impact of films, sheets, and molded products, finding extensive application in packaging and consumer goods. By optimizing pigment dispersion, it reduces solvent usage, boosts production efficiency, and lowers manufacturing costs.

Food Packaging

Food Packaging Injection Molding

Injection Molding Plastic Industry

Plastic Industry

Agricultural Films

Agricultural Films Plastic Products

Plastic Products

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.