Brown Masterbatch

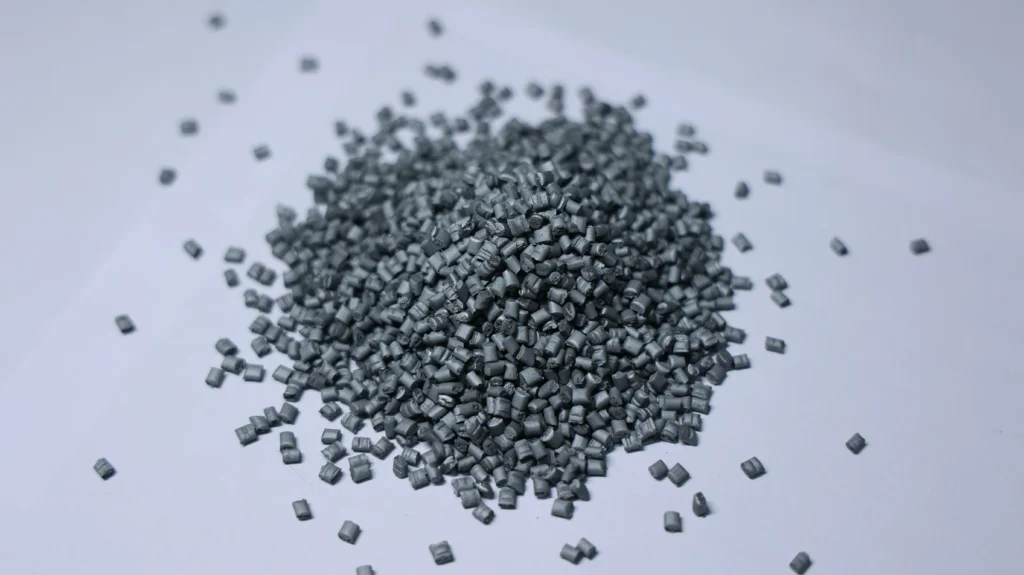

Brown color masterbatch is a high-concentration coloring material manufactured by processing brown pigments, dispersants, and functional additives at high temperatures using polymer resin as a carrier. Brown masterbatch imparts a warm, natural, and stable brown hue to plastic products while offering excellent thermal stability and weather resistance. It is widely used in applications such as appliance housings, packaging products, daily necessities, and building material profiles.

- Color: Brown

- Carrier Materials: PE/PP/PVC/ABS/PET/PS/PA

- Functional Additives: Lubricants, flame retardants, antistatic agents, antioxidants, antibacterial agents, light stabilizers, gloss enhancers, biodegradable additives

- Packaging: 25kg/bag

- Minimum Order Quantity: 1 ton

- Sample: Free 1 kg sample

- Customized: Acceptable

- Payment Terms: T/T, L/C

Price: $1.30 ~ $5.50/kg

Advantages of Brown Masterbatch

Natural and Steady Texture

Utilizing high-purity brown pigments, it offers rich color gradations capable of producing various shades such as coffee brown, dark brown, and bronze brown, imparting an elegant and dignified appearance to finished products.

High Heat and Light Resistance

Withstands processing temperatures exceeding 260°C, making it suitable for long-term use in outdoor or high-temperature environments. It maintains color stability, resisting fading and discoloration.

Excellent Dispersibility

Through the matching of high-quality dispersants and carrier resins, the pigment distributes uniformly within the plastic matrix. This prevents issues like color spots, and streaks, enhancing the aesthetic appeal of the product surface.

Enhanced Processing Performance

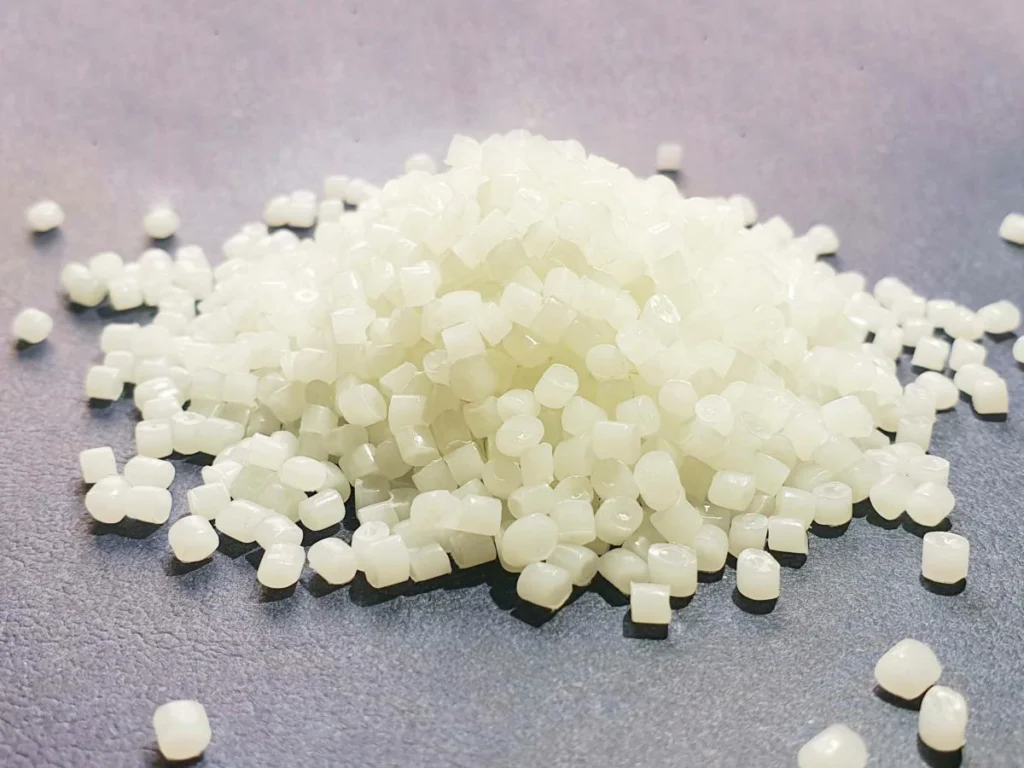

The masterbatch’s granular form ensures uniform mixing, excellent flowability, and improved processing stability of plastics. This reduces energy consumption while boosting production efficiency and surface finish quality.

48-Hour Custom Color Solution

Highly Customizable Service

We formulate specific brown color systems based on customer samples or Pantone references. Functional additives like flame retardants, antimicrobials, and UV stabilizers can be incorporated to balance aesthetics with performance.

Environmentally Friendly & Non-Toxic

Brown masterbatch contains no heavy metals like lead, cadmium, or mercury. It complies with international environmental standards including RoHS and REACH, ensuring safe use in food packaging and children’s toys.

Specifications

Brown colour masterbatch offers diverse formulations. Below are selected technical parameters (customizable per client requirements):

| Carrier | PP/PE/PVC/ABS/PS/PET |

| Color | Brown/Dark Brown/Coffee Brown/( Customized) |

| Light Resistance (Grade 1-8) | 7-8 |

| Temperature Resistance (℃) | 180ºC-300ºC |

| Migration Resistance (Grade 1-5) | 5 |

| Effective Solid Content (%) | 20.0±0.2 |

| Melting Point (℃) | 130-230 |

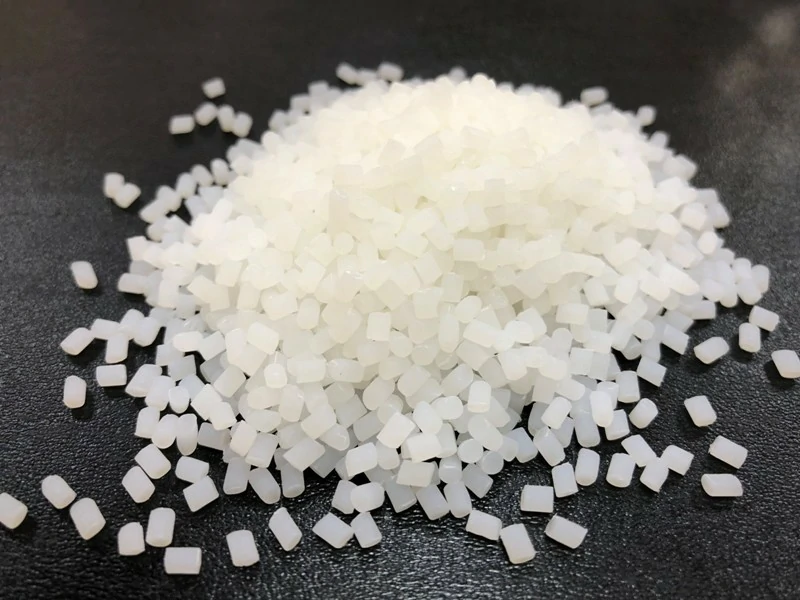

| Grain Size | 2.5 – 3.0mm |

| Moisture Content (%) | ≤0.02 |

| Eco-Friendly | ROHS Compliant |

| Specific Gravity | 1.5 – 1.8 |

Common Types of Brown Masterbatches

- General-purpose brown masterbatch: Suitable for common plastic systems such as PE, PP, and PS. It offers stable processing and moderate cost, making it ideal for everyday injection molding and extrusion products.

- Weather-Resistant Brown Color Masterbatch: Incorporates UV stabilizers and antioxidants, suitable for outdoor applications like building materials, landscaping products, and automotive components, maintaining color stability during prolonged exposure.

- High-Temperature Resistant Brown Master batch: Specifically designed for high-processing-temperature plastics like PA, PC, and PBT. Maintains color stability under heat, suitable for engineering plastic products.

- Food-Grade Brown Colour Masterbatch: Manufactured with FDA-compliant safe raw materials, free from harmful substances. Suitable for food packaging, tableware, and drinking water containers.

- High-gloss brown color master batch: Used for home appliance panels, cosmetic packaging, and similar products, offering high gloss and excellent surface texture.

“Brown Masterbatch in Different Industries .”

.”

– used in film, extrusion, injection molding, foaming

Home Appliance and Electronic Enclosures: Commonly used in televisions, air conditioners, audio equipment, computer accessories, and appliance casings to enhance aesthetic appeal and color depth.

Packaging and Containers: Commonly used in bottle caps, plastic boxes, cosmetic packaging, and food containers to enhance visual recognition and brand identity.

Automotive and Transportation Components: Suitable for dashboards, trim pieces, grilles, etc., featuring color stability, heat resistance, and aging resistance to meet premium interior requirements..

Daily & Consumer Goods: Widely used in storage boxes, trash bins, furniture fittings, stationery, plastic flower pots, etc. Features soft, natural colors balancing aesthetics and practicality.

Construction and Home Goods: Applied to PVC profiles, plastic tiles, decorative panels, etc., improving UV resistance and weatherability with long-lasting color.

Agricultural & Industrial Applications: Applied to agricultural pipes, tool handles, industrial containers, equipment housings, etc., enhancing product durability and longevity.

Optimizing productivity and costs

Brown masterbatch imparts a natural, solid color effect to plastic products, enhancing their texture and visual depth. It is widely used in home goods, building materials, and packaging applications. Its excellent pigment dispersion ensures uniform color and strong coverage, reducing color variation and material waste while effectively lowering costs.

PET-Masterbatch Bottle

PET-Masterbatch Bottle brown masterbatch for storage-box

brown masterbatch for storage-box PVC masterbatch profiles

PVC masterbatch profiles

brown color masterbatch for plastic tiles

brown color masterbatch for plastic tiles brown masterbatch for agricultural pipes

brown masterbatch for agricultural pipes

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.