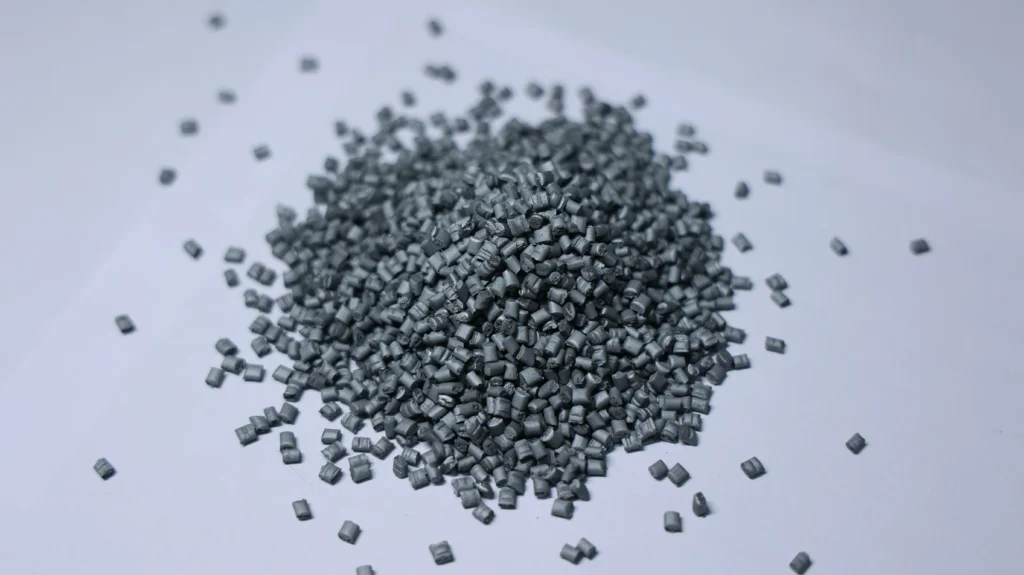

Carbon Black Masterbatch

Carbon black color masterbatch is primarily composed of high-quality carbon black, manufactured through a twin-screw extrusion process. It features excellent high blackness, high brightness, strong coloring power, good dispersion, and versatility. Black color masterbatch is available in both general-purpose and specialized grades, and can be customized according to production requirements.

- Color Powder: Carbon black

- Carrier: PE/PP/PS/ABS/PET/PA6/PA66/TPU

- Dispersing Agents: Polymeric Wax Dispersants, Metal Soaps, Coupling Agents & Surface Modifiers, etc.

- Functional Additives: Lubricants, processing stabilizers, release agents, plasticizers, reinforcing materials, fillers, flame retardants, anti-static agents, anti-fog agents, antimicrobial/mold-inhibiting agents, biodegradable additives, etc.

- Packaging: 25 kg/bag (moisture-proof inner liner + woven bag)

Advantages of Carbon Black Masterbatch

High blackness and excellent dispersibility:

High carbon black content provides strong coloring power, enabling uniform dispersion in various plastic substrates to achieve deep black, bright black, or blue-black effects.

Strong UV protection:

Can be formulated with UV-resistant additives to enhance weather resistance and outdoor service life, suitable for applications such as agricultural films, pipes, and cable jackets.

Compliance with multiple international certification standards:

Customizable eco-friendly formulations compliant with FDA, RoHS, REACH, and other standards, meeting high-standard application requirements such as food contact and medical packaging.

Adjustable color tone and gloss level

Customizable blue, red, or neutral color tones, as well as matte or high-gloss visual effects, according to customer requirements.

48-Hour Custom Color Solution

Suitable for multiple processing methods

Compatible with injection molding, extrusion, blow molding, film blowing, and other processing methods, maintaining stable performance under high-temperature and high-shear conditions.

Multiple carrier options and high-load customization

Offers a variety of carrier options including PE, PP, PS, ABS, and PET, and can be customized for high-concentration or special functional masterbatches based on product requirements.

“Carbon Black Masterbatch For The Perfect Black Pigment .”

.”

– leading turnaround times for color matching

Pipe Industry: Used for coloring PVC, PE, PP, and other materials in water supply and drainage pipes, cable sheathing pipes, and other applications, compatible with various extrusion processes.

Film Packaging: Suitable for coloring plastic films and sheets produced via cast film, extrusion, and blow molding processes, meeting food-grade and industrial packaging requirements.

Sheets and Plates: Provides stable and uniform color effects for ABS, PS, PET, and other sheet and plate materials, ensuring consistent product appearance.

Injection-Molded Products: Suitable for coloring injection-molded parts such as appliance housings, automotive interiors, and daily necessities. Special properties can be achieved by adjusting transparency levels and selecting specific carbon black grades.

Find a tailored solution for Your Industry

Backed by decades of experience in color formulation, Huashuo provides high-accuracy color solutions that consistently exceed industry standards.

Garbage Bag

Garbage Bag Pipes

Pipes Satellite Cable

Satellite Cable

PP Injection

PP Injection Car Decoration

Car Decoration

Specifications

We have rich industry experience and can provide accurate color matching and performance optimization solutions based on the application needs of different industries, such as filler masterbatch, injection molded products, pipe materials, and ABS products. The following are the recommended carbon black masterbatch specifications for various applications for your reference and selection:

Special black masterbatch for Film Blowing

| Item No | Carrier resin | Carbon black content | Temperature resistance | MFI(g/10min) | Addition ratio | Moisture content |

|---|---|---|---|---|---|---|

| 4035E | LDPE, PP | 35% | 120-280℃ | 10.0~45.0 | 1-4% | ≤0.1% |

| 4041E-A | PE+EVA | 41% | 130-220℃ | 10.0~45.0 | 1-4% | ≤0.1% |

| 4057E | LDPE, PP | 57% | 120-280℃ | 10.0~45.0 | 1-4% | ≤0.1% |

Special black masterbatch for Injection Molding

| Item No | Carrier resin | Carbon black content | Temperature resistance | MFI(g/10min) | Addition ratio | Moisture content |

| 4038I | PE,PP | 38% | 120-280℃ | 10.0~45.0 | 1-5% | ≤0.1% |

| 4025I | PE,PP | 25% | 120-280℃ | 10.0~45.0 | 1-5% | ≤0.1% |

Special high-end black masterbatch for pipes

| Item No | Carrier resin | Carbon black content | Temperature resistance | MFI(g/10min) | Addition ratio | Moisture content |

| 4055P | PE | 55% | 120-280℃ | 10.0~45.0 | 2-4% | ≤0.15% |

| 4042P | PE | 42% | 120-280℃ | 10.0~45.0 | 2-4% | ≤0.15% |

ABS Special black masterbatch

| Item No | Carrier resin | Carbon black content | Temperature resistance | MFI(g/10min) | Addition ratio | Moisture content |

| 4050S | ABS | 50% | 135-380℃ | 10.0~35.0 | 1-5% | ≤0.1% |

| 4035S | ABS | 35% | 135-380℃ | 10.0~25.0 | 1-5% | ≤0.1% |

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.