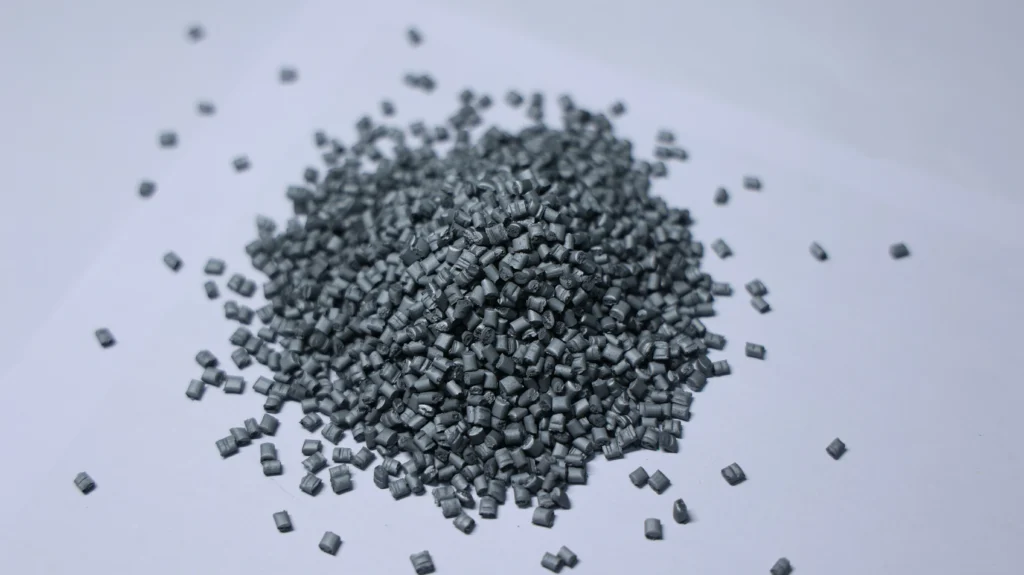

Conductive Masterbatch

Conductive masterbatch is a high-concentration functional masterbatch made by incorporating conductive fillers such as conductive carbon black, carbon nanotubes, or metal powders into a carrier of polyolefin or engineering plastics. It functions by forming a stable conductive network within the plastic, reducing surface or volume resistivity to impart antistatic, electric shock resistance, electromagnetic interference resistance, or conductive properties to the material. Conductive color masterbatch is commonly used in electronic packaging, antistatic containers, and other fields.

- Colors: Black, Gray, Dark Blue, Dark Green, Metallic (Customizable)

- Suitable Base Materials: PE, PP, PS, ABS, PA, PET, etc.

- Processing Methods: Film blowing, Extrusion, Injection molding, Blow molding, etc.

- Minimum Order Quantity: 1 ton

- Sample: Free 1 kg sample

- Customization: Acceptable

- Delivery Time: 7 days after order confirmation.

- Payment Terms: T/T, L/C

aDVANTAGES

Choose conductive color masterbatch to impart electrical conductivity to products

Enhanced Conductivity

Reduces surface resistance, imparting anti-static and electromagnetic interference resistance to products, meeting equipment requirements for electrostatic protection or conductive performance.

Stable Conductive Properties

Establishes a continuous conductive network with long-term stable conductivity, improving product quality and reducing maintenance costs.

Superior Processability

Suitable for multiple processes including injection molding and extrusion. Minimizes carbon black agglomeration or melt fracture during processing, boosting production efficiency.

Excellent Appearance

Even distribution of conductive fillers and pigments ensures smooth product surfaces, avoiding issues of dirt accumulation and color instability common with traditional conductive carbon blacks.

Enhanced Safety

Prevents issues like dust attraction, spark discharge, and electronic component damage caused by static buildup, improving operational safety.

Excellent Compatibility

Compatible with various base resins including PE, PP, and more. Widely used in electronic packaging, anti-static containers, conductive pipes, and other applications.

Specifications

| Product name | Conductive Masterbatch |

|---|---|

| Carrier Resin | PE, PP, PS, ABS (customizable) |

| Conductive Filler | Conductive Carbon Black / Carbon Nanotubes (CNT) / Metal Powder |

| Melt Flow Index (190℃/2.16kg) | 8–20 g/10 min |

| Surface Resistivity | 10⁴–10¹¹ Ω |

| Volume Resistivity | 10³–10⁹ Ω |

| Moisture Content | ≤ 0.2% |

| Density | 1.05–1.22 g/cm³ |

| Processing Temperature | 160–260℃ |

| Ash Content | 0.5–2.0% |

| Recommended Dosage | 10–18% |

| Processing Methods | Injection molding, extrusion, sheet forming, blow molding, thermoforming |

| Packaging | 25kg/bag |

Customized Conductive Masterbatch

Huashuo can customize Conductive colour masterbatches according to your specific requirements, such as color and carrier material, to meet your production needs. Please provide the following informations:

- Target color or color sample (Pantone number, physical sample, or color chart)

- Substrate requirements (PP, PE, PET, etc.)

- Application product type (injection-molded parts, extruded products, sheets, pipes, etc.)

- Addition ratio or application method

- Special requirements (e.g., food-grade certification, environmental standards, surface gloss, etc.)

Applications of Conductive Color Masterbatches

| Industry | Carrier Resin | Loading (%) | Application Fields |

|---|---|---|---|

| Electronics & Semiconductor Packaging | PP / PS / ABS | 10–15% | Anti-static IC trays, Conductive electronic component boxes, Packaging reels, Blister trays |

| Automotive Industry | PP / PA / ABS | 12–18% | Fuel system components, conductive connector fittings, automotive interior functional parts |

| Logistics Storage & ESD Factory Systems | PE / PP / HDPE | 10–16% | Crates, logistics pallets, industrial bins, warehouse antistatic containers |

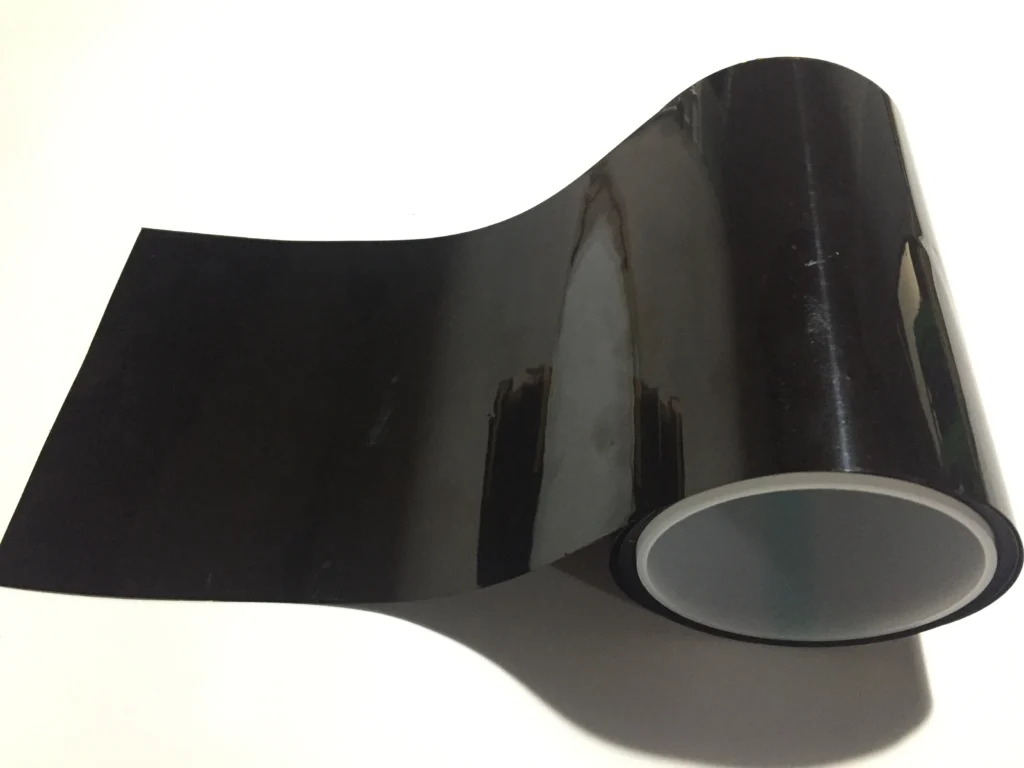

| Packaging Films & Sheets | PE / PP | 8–12% | Electronic Component Protective Films, Packaging Bags, Dust-Proof Films, Sheets/Thermoformed Sheets |

| Pipe & Profile Manufacturing | PE / PP | 12–18% | Conductive Gas Pipes, Chemical Conveyance Pipes, Cable Protection Pipes |

| Appliance and Equipment Housings | ABS / PC / PP | 10–14% | Printer components, industrial control equipment housings, conductive parts for office equipment, smart home components |

“Common Types of Conductive Masterbatch ”

”

Various types of conductive color masterbatches impart electrical conductivity to products

Carbon Black Conductive Masterbatch: Primarily composed of highly structured conductive carbon black, it achieves stable surface resistance through the formation of a conductive network. Suitable for packaging, electronics, and automotive components.

Graphene Conductive Color Masterbatch: Leveraging graphene’s superior conductivity and thermal stability, it delivers lightweight yet highly efficient conductivity, suitable for high-performance films and electronic packaging.

Metal Powder Conductive color Masterbatch: Incorporates metal particles like copper, nickel, or silver powders to impart high conductivity to products. Primarily used in high-end applications such as electronic components and sensor housings.

CNT Conductive Master batch: Achieves extremely low resistance via the three-dimensional conductive structure of carbon nanotubes. Suitable for high-standard anti-static pallets, semiconductor transport containers, etc.

Metal Fiber Conductive Masterbatch: Incorporates stainless steel fibers or metal wires to form conductive pathways, offering robust conductivity ideal for demanding anti-static or electrostatic shielding applications.

Anti-static Masterbatch: A transfer-type formulation that forms an anti-static layer through interfacial migration. Suitable for packaging materials and short-term anti-static applications.

Conductive Masterbatchs in Plastic

conductive connector fittings

conductive connector fittings ESD plastic pallet

ESD plastic pallet conductive protective film

conductive protective film

enclose EMI shielding

enclose EMI shielding conductive gas pipes

conductive gas pipes

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.