Gold masterbatch

Gold Masterbatch is a high-concentration coloring material formulated by blending gold pigments, additives, and dispersants into a polymer resin carrier. Primarily used for metallic coloring in plastic products, it imparts a dazzling, sophisticated, and premium metallic finish. Offering advantages such as color durability, strong weather resistance, and low cost, Gold color masterbatch is widely applied in packaging, home appliances, electronic casings, and other fields.

- Color: Gold

- Carrier Materials: PP/PC/ABS/PE/PVC/PA/PET/HIPS

- Dispersants: Polyethylene wax, polypropylene wax, stearate, hydroxystearate, laurate

- Functional Additives: Lubricants, antioxidants, flame retardants, antistatic agents, light stabilizers, anti-fog agents, antibacterial agents, antifungal agents

- Packaging: 25KG/bag

- Payment Terms: T/T, L/C

Advantages of gold Masterbatch

Golden Hue with Dazzling Brilliance

Utilizing high-brightness metallic or pearlescent pigments, the finished product exhibits a refined metallic sheen and reflective effect, enhancing its dimensionality and premium feel.

Superior Dispersibility

Golden pigments are thoroughly blended with additives, achieving uniform distribution within the plastic matrix. This minimizes color variations, spotting, and streaking, elevating the aesthetic appeal of the golden finish.

High Heat and Weather Resistance

Incorporating UV stabilizers and antioxidants protects against ultraviolet radiation, humidity, and oxidation, ensuring long-lasting color stability for outdoor applications.

Processing Stability

Gold master batch withstands elevated processing temperatures without discoloration or decomposition. Compatible with diverse thermoplastic resins, it maintains consistent color performance across injection molding, extrusion, and other manufacturing processes.

48-Hour Custom Color Solution

High Customizability

We offer exclusive color matching services based on customer-provided color charts (Pantone) or samples, ensuring rapid customization and precise color accuracy.

Environmentally Friendly & Safe

Free from heavy metals, halogens, or harmful solvents, compliant with international environmental standards like ROHS and REACH. Suitable for food packaging, children’s products, and cosmetic containers.

Specifications

Gold masterbatch offers both visual appeal and robust functionality, suitable for diverse plastic industries while combining aesthetics with practicality. Below are key specifications for gold colour masterbatch:

| Index | Value |

| Carrier | PP/PE/PC/ABS/PA (Can be customized) |

| Color | Gold/platinum-blond/rose gold/golden brown (can be customized) |

| Light Resistance (Grade 1-8) | 8 |

| Temperature Resistance | 160ºC-300ºC |

| Migration Resistance (Grade 1-5) | 5 |

| Melting Point (℃) | 100-280 |

| Grain Size | 2-3.5mm |

| Eco-Friendly | ROHS compliant |

| Dispersion | High |

| Gloss Grades | High gloss |

We accept samples for testing, Pantone color matching, and even final product samples for analysis. If you are interested in gold or other masterbatches, please contact us. We provide customized color matching and functional customization services based on your specific needs.

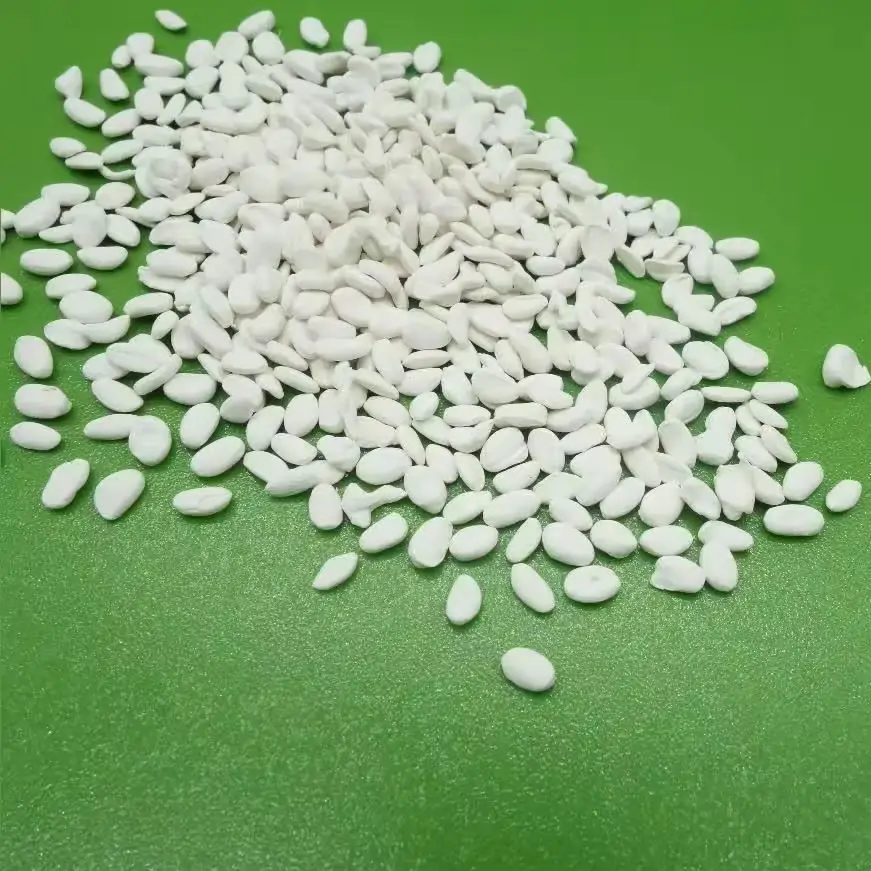

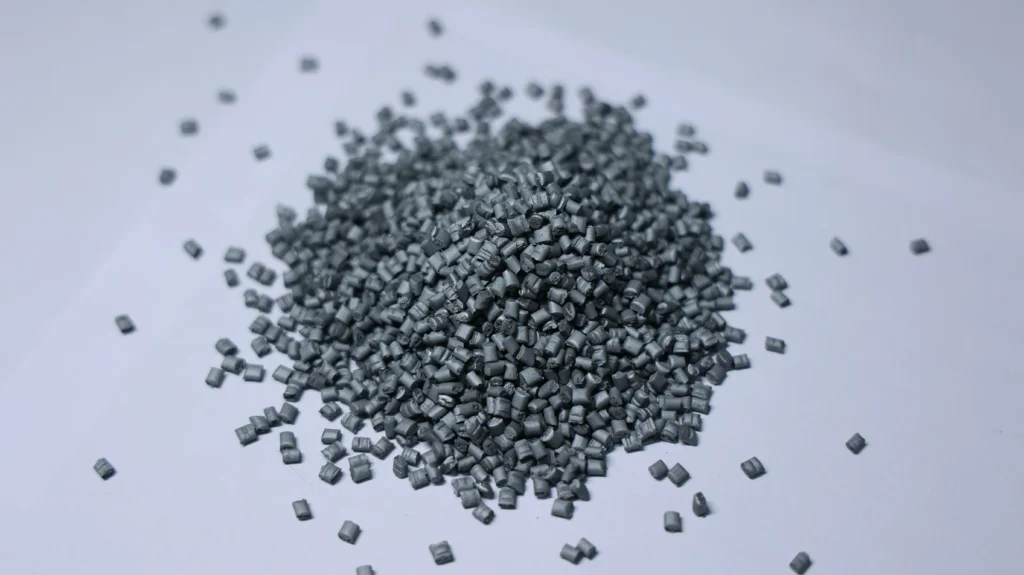

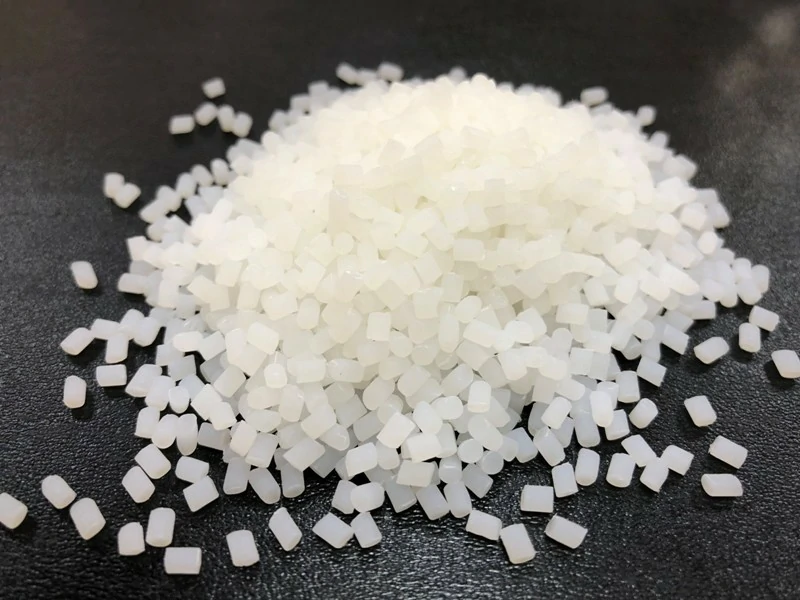

gold masterbatch

gold masterbatch

Common Types of gold Masterbatches

- Bright Gold Master batch: Features high gloss and strong reflective properties, commonly used in premium electronics and decorative components for striking visual impact.

- Matte Gold Color Masterbatch: Offers a soft, non-glare finish ideal for luxury packaging, automotive interiors, and other applications prioritizing texture.

- Pearl Gold Masterbatch: Incorporates pearlescent pigments to create a silky, delicate reflective effect, frequently used in cosmetic containers and appliance housings.

- Metallic Gold Colour Masterbatch: Incorporates high-purity metallic powders or coated pigments to create intense metallic reflections, commonly used in decorative panels, logos, and other premium applications.

- Outdoor Gold Master batch: Specifically engineered for outdoor products, offering excellent UV resistance and weather stability, suitable for lamp housings, construction projects, and similar applications.

“Gold Masterbatch in Different Industries .”

.”

– used in film, extrusion, injection molding, foaming

Packaging Industry: Commonly used in cosmetic bottles, gift boxes, and food packaging films, enhancing product aesthetics with a luxurious and distinctive appearance to elevate brand value.

Home Appliance Industry: Widely applied in TV bezels, air conditioner panels, rice cooker housings, and other components. Replacing electroplated parts with metallic-effect plastics offers both visual appeal and environmental sustainability.

Automotive Manufacturing: Widely used in interior components (dashboards, trim strips, knobs) and exterior parts, showcasing a premium metallic texture with strong visual appeal.

Consumer Electronics: Commonly found in small electronic products like phone cases, headphones, and computer accessories, imparting a high-tech aesthetic to meet consumer fashion demands.

Building Materials Industry: Used in plastic profiles, window frames, and home decoration accessories, enhancing UV resistance and oxidation resistance. Offers weather resistance and durability, suitable for outdoor environments.

Lighting Industry: Possesses excellent heat resistance, commonly used in lamp housings, lampshades, and decorative components. The metallic luster elevates the overall product quality and enhances spatial decorative effects.

Optimizing productivity and costs

Gold masterbatch imparts a noble, elegant metallic texture and visual luster to plastic products, creating a luxurious, refined, and textured appearance. It is widely used in decorative components, building materials, and packaging products. By optimizing pigment dispersion and carrier compatibility, it enhances color brightness and coverage, boosting product aesthetics and market competitiveness while reducing color variation and material waste during production, effectively lowering costs.

cosmetic bottles

cosmetic bottles daily supplies

daily supplies food packaging films

food packaging films

PVC pipe

PVC pipe automobile interior

automobile interior

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.