PC Masterbatch

PC Masterbatch (Polycarbonate Masterbatch) is a concentrated pellet formed by processing high-concentration pigments, functional fillers, and additives through specific techniques using polycarbonate (PC) as the carrier. It exhibits high compatibility with PC substrates, featuring high-temperature resistance and superior transparency. Suitable for engineering plastic products such as electronics, electrical components, and optical parts.

- Colors: Clear, Black, Fluorescent, Metallic Silver ( customized available)

- Functional Additives: UV Stabilizers, Antistatic Agents, Anti-Yellowing Agents, Flame Retardants, Light Diffusers, etc.

- Application Processes: Injection Molding, Blow Molding, Extrusion Molding, PC Alloy Processing, etc.

- Minimum Order Quantity: 1 ton

- Sample: Free 1 kg sample

- Customization: Acceptable

- Payment Terms: T/T, L/C

Advantages

Preserves PC Properties: High compatibility maintains PC’s inherent advantages, including high transparency, impact strength, and oil resistance, enhancing competitiveness.

Excellent High-Temperature Resistance: Utilizing PC resin as the carrier, it withstands processing temperatures of 260–300°C without decomposition or discoloration, making it suitable for high-temperature processes like injection molding and extrusion.

High Compatibility with PC Base Material: Matching the melt index of PC resin base material ensures uniform dispersion of pigments in the product, without compromising transparency or mechanical properties.

High Tinting Strength: Exceptional color concentration allows achieving the same effect with 10% masterbatch pigment content compared to 30% conventional pigment, effectively reducing costs and minimizing equipment cleaning frequency.

Easy Handling: PC masterbatch comes in granular form, facilitating precise metering and mixing. No additional process parameter adjustments are required, improving processing flow and saving time.

Excellent Environmental Compliance: Meets international standards such as ROHS, REACH, and FDA as required. Free from heavy metals and odors, suitable for electronic, medical, and food packaging products.

Strong Functional Expansion: Can incorporate functional additives like flame retardants, UV stabilizers, and antistatic agents for multifunctional applications, enhancing the comprehensive performance of finished products.

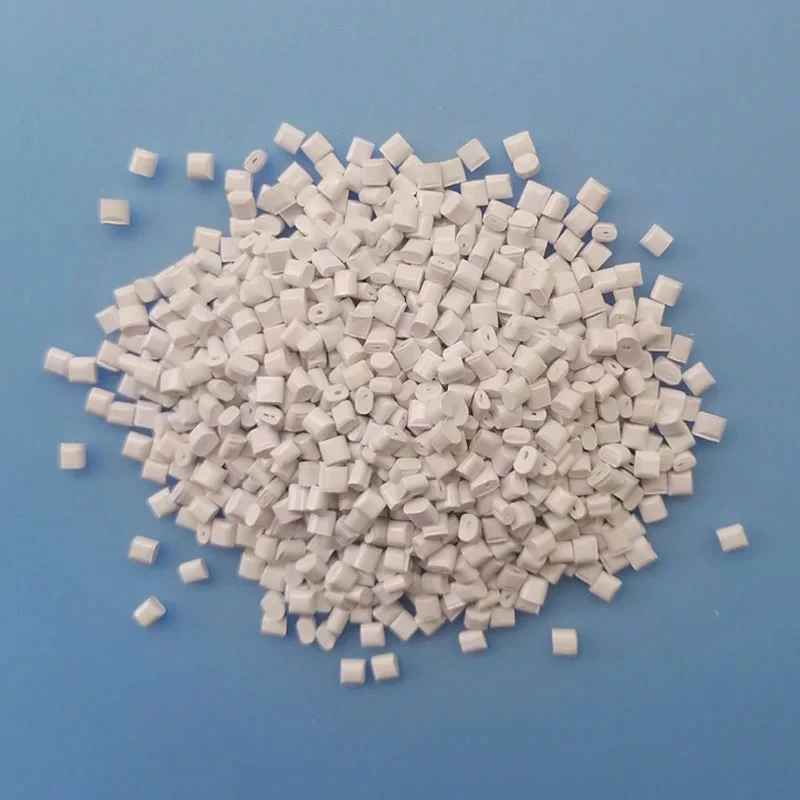

PC Color Masterbatch

PC Color Masterbatch PC-White-Masterbatches

PC-White-Masterbatches UV-Resistant PC Masterbatch

UV-Resistant PC Masterbatch PC-Masterbatch

PC-Masterbatch

Production Process of PC Masterbatch

The production process of PC color masterbatch primarily includes the following steps:

1. Raw Material Screening: Typically involves selecting high-temperature resistant inorganic pigments or high-performance organic pigments, premium resins with excellent flow and mechanical properties, and additives meeting specific requirements, such as flame retardants.

2. Formulation Design: Calculate pigment and additive ratios based on target color or functional requirements. Develop precise formulations and pre-mix raw materials in machinery to ensure uniform distribution.

3. Melt Compounding: Pre-mixed materials undergo high-temperature heating and blending via twin-screw extruders. Impurities are removed through screens to enhance PC master batch purity.

4. Cooling and Pelletizing: The extruded PC melt (ribbon form) is typically cooled via water cooling (water bath cooling) or air cooling before being cut into pellets of the desired size.

5. Quality Inspection: Parameters such as appearance, particle size, color difference, melt index (MI), and thermal stability are tested. Non-conforming pellets are screened out to ensure batch consistency and application reliability.

6. Packaging and Storage: Masterbatch meeting quality standards is sealed in packaging, typically woven bags or composite bags, to prevent moisture ingress and maintain performance and appearance.

Common Types of PC Masterbatches

High-Gloss PC Color Master batch: Features high color stability with minimal haze or gloss loss, delivering high brightness, excellent color saturation, and superior surface finish. Commonly used in electronic enclosures, automotive interior components.

UV-Resistant PC Masterbatch (Weather-Resistant): Incorporates UV stabilizers to enhance yellowing resistance and outdoor weatherability. Suitable for outdoor transparent sheets, lighting shades, and security equipment housings.

Transparent PC Color Masterbatch: Utilizes high-transmittance pigment systems to maintain PC’s inherent transparency while achieving subtle tinting. Primarily used in light diffusion components, transparent electronic parts, and optical components.

Flame-Retardant PC Masterbatch: Incorporates halogen-free flame retardants to achieve UL94 V0 or V2 ratings. Widely used in home appliances and electronics to enhance safety standards.

Functional PC Master batch: Offers multiple functional properties including antistatic, antibacterial, scratch-resistant, and light-diffusing effects. Suitable for high-tech applications such as optical components and camera assemblies.

Specifications

| Test Item | Specification Data |

|---|---|

| Product name | PC Masterbatch |

| Appearance | Cylindrical or flat granular |

| Pigment Content | 20%–60% (customized) |

| Carrier Resin | 100% PC resin |

| Melting Point | 250–320°C |

| Haze | ≤1% |

| Volatile Content | ≤0.3% |

| Addition Ratio | 1%–4% |

| Moisture Content | ≤0.1% |

| Melt Index | 5–15 g/10 min |

| Processing Temperature Range | 250–300°C |

| Suitable Processes | Extrusion/Injection Molding/Blow Molding |

| Packaging | 25kg/bag (OEM/ODM supported) |

The above are partial parameters of PC master batch for reference. If you are interested in our masterbatches, or would like to learn more about PC color masterbatch market prices and other information, please contact us. We will answer your questions and provide customized formulation services.

Customized PC Masterbatches

Custom PC colour masterbatch requires the following information from you:

- Final product type: e.g., blown film, injection molded, extrusion etc.

- Target color standard: Provide Pantone color number, RAL color number, or physical color sample.

- Color fastness requirements: Such as migration resistance, lightfastness (UV resistance), heat resistance rating.

- Processing method and temperature: e.g., profile extrusion(230-280°C), injection molding (260-300°C), etc.

- Special Functions: Require additional properties such as anti-UV, Flame retardant fountion?

Our color masterbatch experts will contact you within 2 hours to provide complimentary color matching solutions and comprehensive technical support!

“PC Masterbatchs in Different Industries ”

”

– Pc colour master batch is widely used in the following fields

PC master batch offers multiple properties including high transparency, high strength, and high heat resistance, making it widely applicable across various industries. Below are some primary application areas:

Electronics and Appliances: Extensively used in computers, mobile phones, and control panels to provide high gloss, flame retardancy, and anti-yellowing coloring effects.

Automotive Components: Employed in interior trim, dashboards, buttons, and decorative moldings to enhance heat resistance, weatherability, and impact strength.

Lighting & Optical Components: Suitable for lampshades, optical lenses, and transparent covers, maintaining high light transmission while improving resistance to yellowing.

Household Goods: Commonly used in kettle housings, protective covers, and packaging bottles, meeting environmental and safety standards with excellent impact resistance.

Construction field: Primarily used in industrial components, PC sun panels, flame-retardant PC pipes, etc., improving weather resistance and service life.

Medical field: Suitable for medical device housings, infusion set accessories, etc., enhancing flame retardancy and chemical corrosion resistance.

PC Masterbatchs in Plastic

PC color masterbatch possesses excellent heat resistance, dispersibility, and color stability, making it widely used in electronics, transparent sheets, and optical products. Using PC masterbatch instead of in-situ color mixing not only improves production efficiency but also reduces pigment scattering and waste, effectively lowering overall manufacturing costs.

Electronics and Appliances

Electronics and Appliances PC Sun Panels

PC Sun Panels Lampshades

Lampshades

Automotive-Interior-Trim

Automotive-Interior-Trim Enclosures for Medical Device

Enclosures for Medical Device

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.