PET Masterbatches

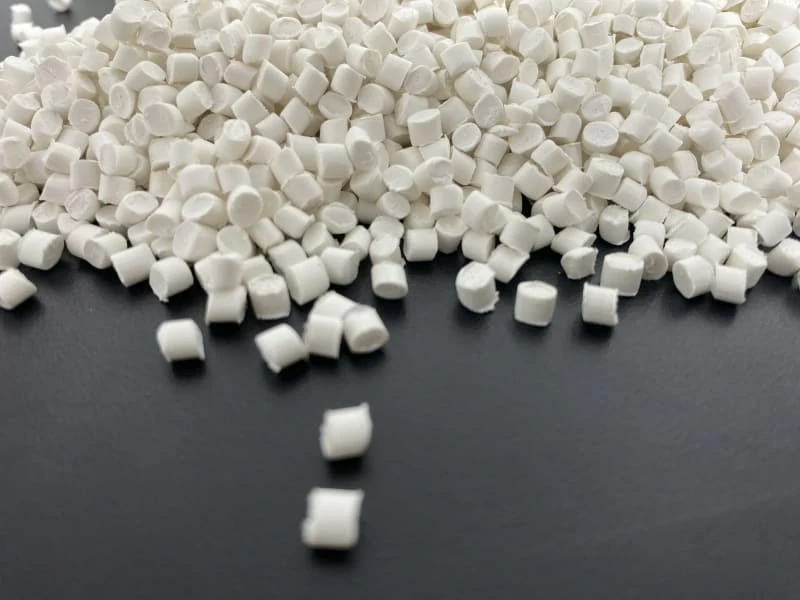

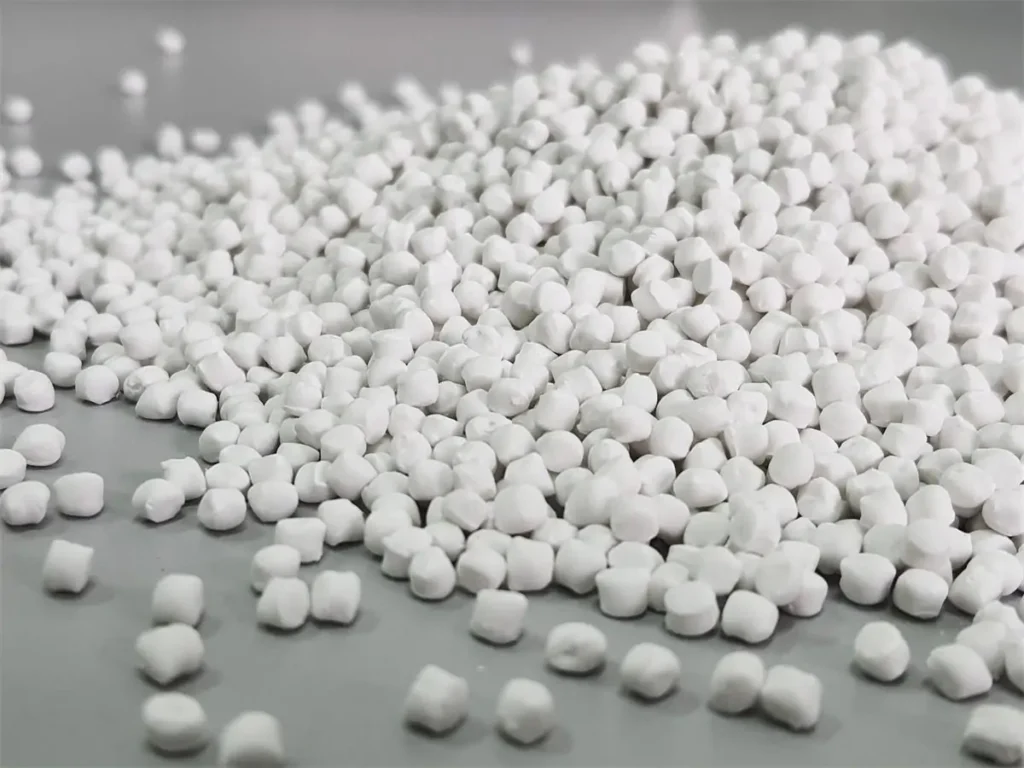

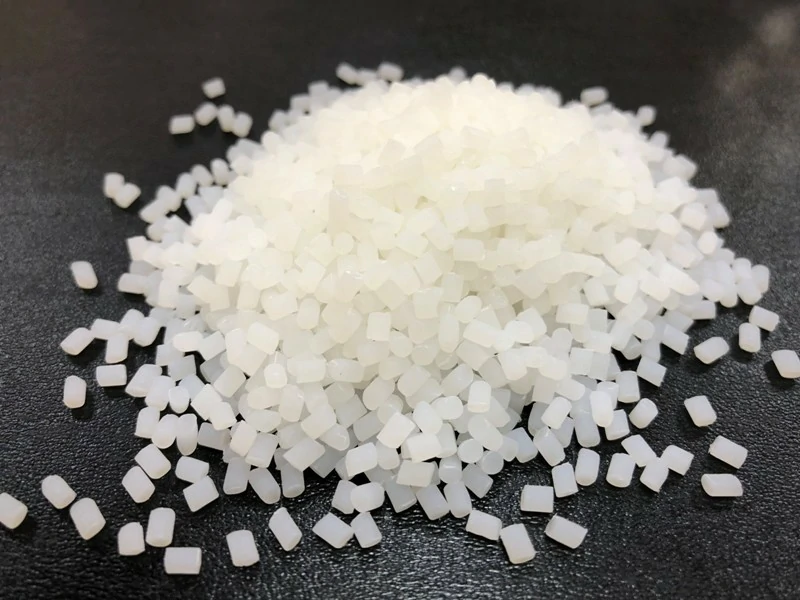

PET masterbatch is a colorant compound manufactured by melt-mixing and pelletizing polyethylene terephthalate (PET) resin with high-concentration pigments and functional additives. It features high transparency, strong color stability, and heat resistance, making it suitable for various Processing technology. It is widely used in industries such as PET preforms, bottles, and films.

- Colors: Transparent, Black, Pearlescent, Metallic ( customized available)

- Functional Additives: UV Stabilizer, Antioxidant, Anti-Yellowing Agent, Heat Stabilizer, Brightener, etc.

- Application Processes: Injection Molding, Blow Molding, Sheet Extrusion, Fiber Spinning, BOPET Biaxially Oriented Film, etc.

- Minimum Order Quantity: 1 ton

- Sample: Free 1 kg sample

- Customization: Acceptable

- Delivery Time: 7 days after order is confirmed

- Payment Terms: T/T, L/C

Processing techniques for PET master batch

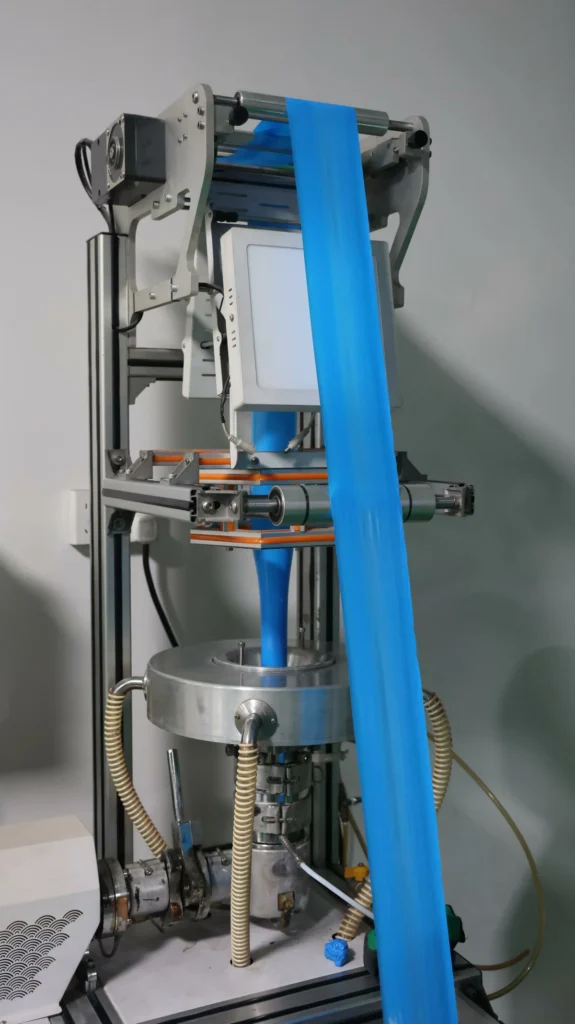

PET color masterbatch is commonly used in various polyester processing techniques, delivering excellent dispersion and color stability in the molten state. Below are the most common processing methods for PET masterbatch:

Injection Molding: Primarily used for PET preforms and transparent containers, with typical processing temperatures ranging from 260–300°C. During injection molding, PET colour masterbatch rapidly melts and thoroughly blends with PET resin, ensuring uniform color and high transparency in preforms. This process does not affect PET’s inherent viscosity, maintaining excellent stretchability and mechanical strength during subsequent blow molding.

Extrusion Molding: Widely applied for PET sheets, packaging films, and BOPET films. Color masterbatch must exhibit high temperature resistance and excellent melt dispersion to prevent color streaks, yellowing, or crystallization during high-speed extrusion. High-quality PET master batch enhances film gloss, thickness uniformity, and overall optical performance.

Stretch Blow Molding: PET preforms undergo biaxial stretching and blow molding after heating, producing beverage bottles, mineral water bottles, oil containers, and similar products. During stretching, the bottle walls achieve uniform thickness and stable color without decomposition or migration. The finished products feature refined appearance and minimal color variation, meeting stringent aesthetic requirements in the packaging industry.

Co-extrusion: Suitable for producing multi-layer PET structural materials like high-barrier films, protective films, and functional packaging sheets. Masterbatch for PET must exhibit excellent interlayer compatibility within multi-layer structures, ensuring color is uniformly distributed within the target layer without migrating to other structural layers.

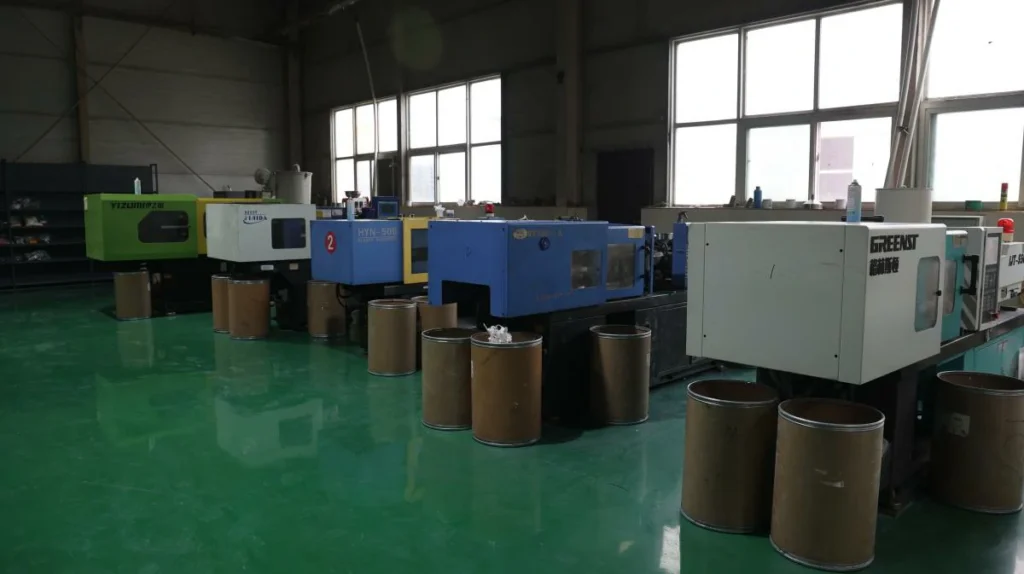

Color Masterbatch Equipment

Color Masterbatch Equipment Color Masterbatch Equipment

Color Masterbatch Equipment Processing Equipment

Processing Equipment Processing Equipment

Processing Equipment

Advantages

- High Transparency: PET color master batch maintains brightness and clarity during high-temperature processing, reducing color spots and haze while enhancing overall visual appeal. Ideal for transparent or translucent products.

- Excellent Dispersibility: Pigments disperse uniformly within the PET matrix, improving coloration efficiency and reducing required dosage. Typically achieves desired hues with minimal addition, without compromising bottle strength or transparency.

- Superior Thermal Stability: Exhibits outstanding heat resistance and degradation resistance, accommodating high processing temperatures (250–300°C). Prevents yellowing or color drift during processing, enhancing product quality.

- No Impact on Mechanical Properties: Does not alter PET’s inherent viscosity (IV value) nor affect product compressive strength, bottle rigidity, or impact resistance.

- Environmentally Safe: Meets international food-grade standards including FDA, EU, and RoHS requirements, ensuring safety and reliability for applications such as mineral water bottles, edible oil containers, and cosmetic packaging.

- Highly Customized: Offers color customization based on Pantone, RAL, or physical samples, providing opaque, transparent, pearlescent, fluorescent, and other effects to rapidly match brand visual requirements.

PET-Masterbatchs-Supplier

PET-Masterbatchs-Supplier PET-Masterbatch

PET-Masterbatch PET- Green-Masterbatch

PET- Green-Masterbatch

Common Types of PET Colour Masterbatches

Standard PET Masterbatch: Suitable for general coloring of most preforms, sheets, and films. Offers high cost-effectiveness and excellent dispersion, ideal for mass production.

High-Transparency PET Color Masterbatch: Preserves PET’s inherent transparency, suitable for products requiring high clarity such as mineral water bottles and purified water bottles.

Anti-Yellowing PET Master batch: Incorporates antioxidant and anti-thermal degradation systems to minimize yellowing during processing and storage, suitable for high-temperature, long-cycle processing.

Food-Grade / FDA-Grade PET Colour Masterbatch: Utilizes food-grade pigments and additives, compliant with FDA/EU food-grade standards, suitable for beverage bottles and food packaging.

Functional PET Masterbatch: Includes UV-resistant masterbatch, optical brightening masterbatch, anti-migration masterbatch, anti-fog masterbatch, etc., imparting additional properties to finished products.

PET masterbatch comes in diverse types, covering a wide range of applications from basic coloring to performance enhancement. It delivers stable performance across various processing scenarios, improving both the appearance and functionality of finished products.

Specifications

| Test Item | Specification Data |

|---|---|

| Product name | PET Masterbatch |

| Appearance | Uniform color,no impurity granular |

| Pigment Content | 10–50% (customized) |

| Particle Size | 2.0×3.0mm |

| Carrier | PET or Copolymer PET |

| Density | 1.25 – 1.45 g/cm³ |

| Intrinsic Viscosity | 0.60 – 0.80 dl/g |

| Moisture Content | ≤0.1% |

| Melt Index | 10–25 g/10 min |

| Melting Point | 240–260°C |

| Suitable Processes | Extrusion/Injection Molding/Stretch Blow Molding |

| Packaging | 25kg/bag (OEM/ODM supported) |

The above are partial parameters of PET master batch for reference. If you are interested in our masterbatches, or would like to learn more about PET masterbatch market prices and other information, please contact us. We will answer your questions and provide customized formulation services.

Customized PET Masterbatches

Custom PET color masterbatch requires the following information from you:

- Final product type: e.g., blown film, injection molded, extrusion etc.

- PET base material used: e.g., pet or others.

- Target color standard: Provide Pantone color number, RAL color number, or physical color sample.

- Color fastness requirements: Such as migration resistance, lightfastness (UV resistance), heat resistance rating.

- Processing method and temperature: e.g., film blowing (160-220°C), injection molding (200-260°C), etc.

- Special Functions: Require additional properties such as anti UV, antifog?

Our color masterbatch experts will contact you within 2 hours to provide complimentary color matching solutions and comprehensive technical support!

“PET Masterbatchs in Different Industries ”

”

– PET colour master batch is widely used in the following fields

PET Bottle-Grade Packaging: Suitable for transparent or colored preforms such as mineral water bottles and beverage bottles, providing stable coloring, high transparency, and food-grade safety, adapted for high-speed blow molding processes.

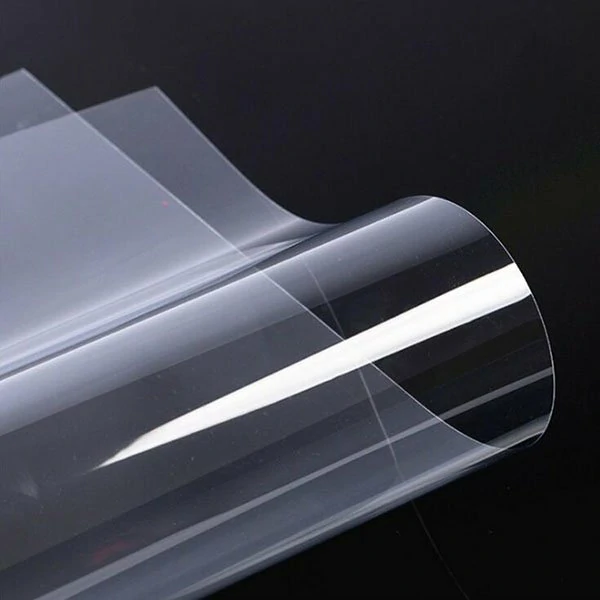

PET Sheets: Suitable for food containers, thermoformed packaging, and transparent folding boxes. Maintains sheet gloss and excellent stretch and thermoforming properties during extrusion, enhancing visual appeal and product value.

Engineering Plastics: Used for coloring reinforced PET or composite materials, such as appliance housings and electronic components, delivering high-temperature resistance and weatherability.

BOPET Film: Widely used in high-performance films for packaging, printing, and insulation. Features excellent thermal stability and light resistance, with uniform coloration free of streaks, crystalline spots, or color variations.

Cosmetic & Personal Care Packaging: Used for premium colored bottles and personal care product containers. Delivers special effects like gloss, pearlescence, and frosted finishes to strengthen brand visuals.

PET Fiber & Filament: Suitable for short staple fibers, continuous filaments, carpet yarns, and industrial fibers. Provides stable dispersion, migration-resistant color performance, and long-term durability.

PET Masterbatchs in Plastic

PET masterbatch maintains excellent thermal stability and dispersibility under high-temperature processing conditions, resulting in products with higher transparency and color performance. It is suitable for various processing techniques such as PET bottle blowing, sheet production, and film production, improving product appearance quality and production efficiency.

PET for Medical Bottles

PET for Medical Bottles PET-Sheet

PET-Sheet Engineering Plastics

Engineering Plastics

BOPET Films

BOPET Films PET 3D Print Filament

PET 3D Print Filament

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.