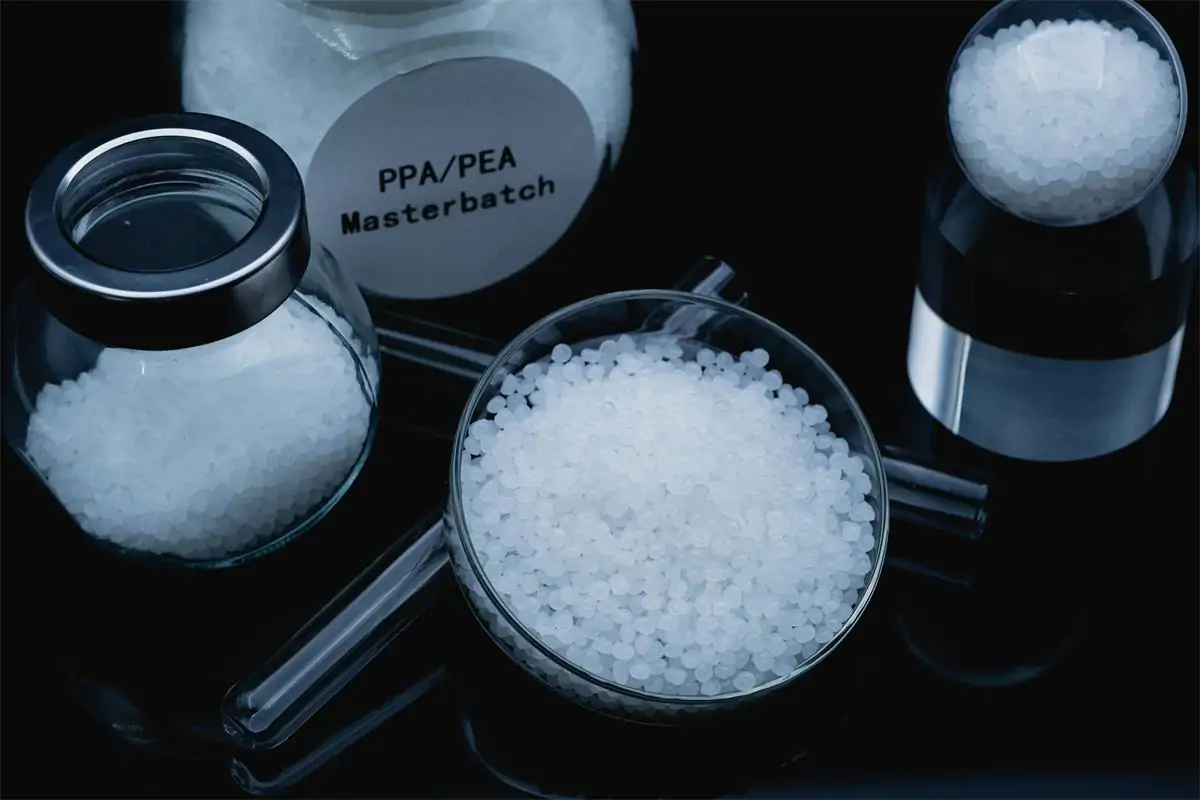

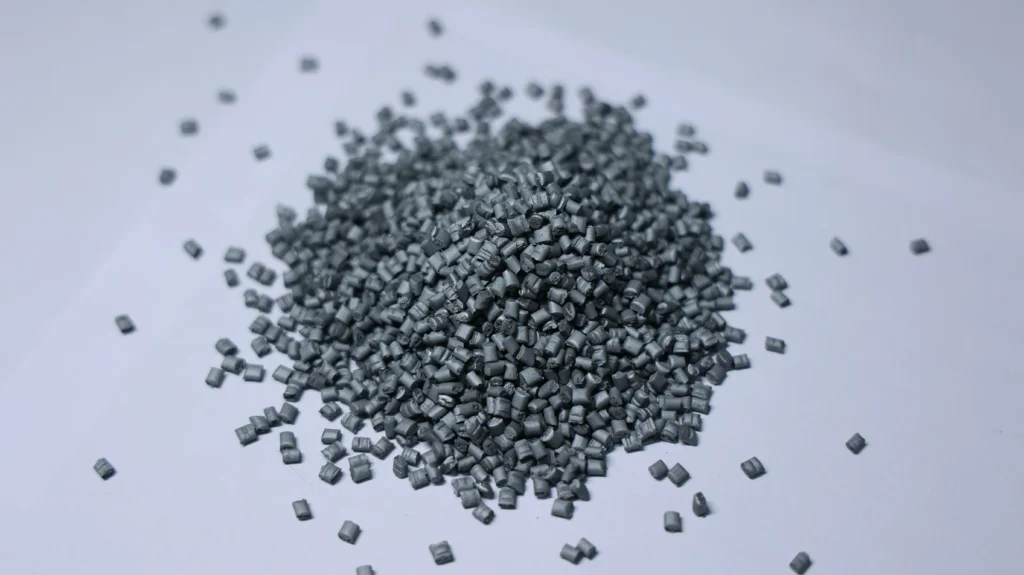

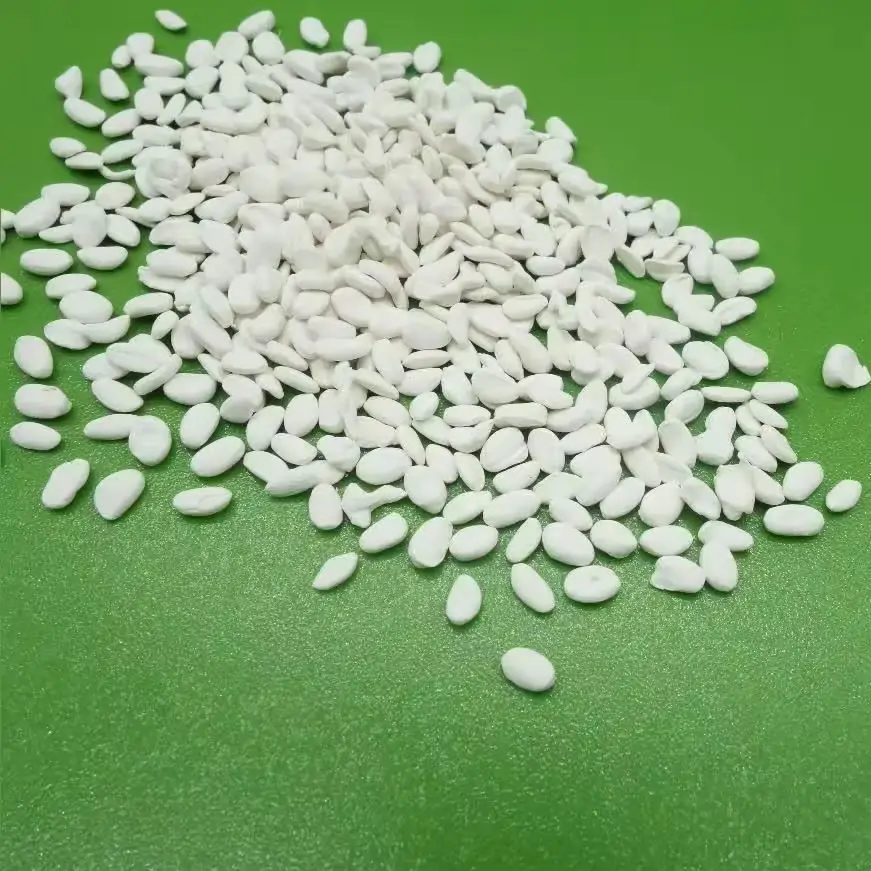

PP Masterbatch

PP Masterbatch is a plastic masterbatch that uses polypropylene as its carrier resin, uniformly dispersing high-concentration pigments and additives within the polypropylene matrix. During plastic product manufacturing, simply adding an appropriate amount of PP color masterbatch can alter the color, functionality, or processing properties of the plastic product, significantly boosting production efficiency and enhancing the functionality of the plastic items.

- Color: Transparent, black, white, red, blue, green, yellow, or custom colors.

- Applications: Injection molding, blow molding, fiber spinning, extrusion molding, and other processes.

- Applications: Injection molding, blow molding, fiber spinning, extrusion molding, etc.

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmed

- Payment Terms: T/T,, L/C

PP Masterbatch Characteristics

Polypropylene (PP) is one of the most widely used thermoplastics globally, making it the optimal choice for plastic carriers:

- Lightweight: Ideal for manufacturing products with weight constraints, such as disposable plastic tableware and thin-walled injection-molded items.

- Chemical Resistance: Suitable for producing chemical containers, pipelines, and similar applications.

- Excellent Mechanical Properties: Well-suited for manufacturing products subjected to pressure and weight, such as industrial plastic pallets and plastic furniture frames.

- Thermal Stability: Maintains performance integrity under elevated temperatures, making it suitable for products requiring high-heat processing like microwave-safe tableware.

- Food Safety: Specific grades meet FDA standards, making it the most popular choice for food packaging.

Advantages

- Superior Dispersibility: Pigments or additives disperse uniformly within the polypropylene carrier resin, ensuring consistent coloration and stable functional properties in plastic products.

- Excellent Stability: The carrier resin isolates pigments and additives from external environments, effectively preventing degradation caused by moisture, oxygen, light exposure, and other factors, thereby extending shelf life.

- Streamlined Production Process: During plastic manufacturing, simply add PP color masterbatch in the required proportion. This simplifies production steps, enhances efficiency, and reduces quality issues.

- Precise Measurement and Color Matching: PP masterbatch exists in granular form, enabling accurate and convenient dosing with easy control over addition rates. For color requirements, professional color matching systems ensure precise formulation, guaranteeing consistent product hues and minimizing quality defects in mass production.

- Precise metering and color matching: PP masterbatch pellets offer accurate and convenient metering, facilitating precise control over addition rates. Professional color matching systems enable exact color formulation, ensuring consistent product hues across every production run. This meets the demands of large-scale manufacturing and stringent requirements for color stability.

PP Masterbatch Application in Plastic Processes

Injection Molding

During injection molding, PP masterbatch and polypropylene raw material are added to the injection molding machine’s hopper at a predetermined ratio. As the screw rotates, the material is heated and melted within the barrel while thoroughly mixed. It is then injected at high speed through the machine’s nozzle into the mold cavity, where it cools and solidifies to form the plastic product.

Typically, the barrel temperature settings are recommended as follows: front section 200–240°C, middle section 210–250°C, rear section 180–220°C. Specific temperatures require fine-tuning based on the characteristics of the actual PP raw material and PP Masterbatch used.

Blow Molding

For blow molding, Masterbatch PP is thoroughly blended with polypropylene resin. The mixture is extruded into a tubular parison via an extruder. The parison is then placed into a blow mold, where compressed air is introduced to expand it and conform to the mold cavity. Upon cooling, this forms hollow plastic products such as bottles or containers.

During blow molding, the extruder temperature can be controlled between 180–230°C, while the blow mold temperature is maintained at 20–50°C.

Extrusion Molding

When producing plastic pipes, sheets, and similar products via extrusion molding, Masterbatch PP is thoroughly mixed with polypropylene raw material in the hopper. After melting and plasticizing in the extruder, the material is extruded through a specific die to form the desired shape.

For example, in pipe production:

- Feed section: 180–200°C

- Compression section: 200–220°C

- Homogenization section: 220–240°C

- Die temperature: 210–230°C

For sheet production, temperatures may be adjusted based on sheet thickness and PP raw material properties.

Specifications

| Test Item | Specification Data |

|---|---|

| Appearance | Uniform color,no impurity |

| Color | Black,White,Red,Green,Blue,Yellow (Pan tone,RAL card) |

| Particle Size | 2.0×3.0 |

| Carrier | PE,PP,ABS etc |

| Moisture (%) | ≦0.1 |

| Heat Resistance (℃) | 160-350 |

| Transference Resistance | 4-5 grade |

| Light Resistance | 4-8 grade |

Custom pP Masterbatches

- Beyond color, we specialize in creating functional Masterbatch PP to upgrade your products:

- White Masterbatch: High-titanium-dioxide content for maximum opacity and whiteness.

- Black Masterbatch: Carbon-black based for deep blacks and UV protection.

- Additive Masterbatch: Concentrated with additives like UV stabilizers, antifogging, flame retardants, or antioxidants.

- Filler Masterbatch: Contains mineral fillers (e.g., Calcium Carbonate) to reduce cost and improve stiffness.

“PP Masterbatch in Different Industries .”

.”

– used in film, extrusion, injection molding, foaming

Packaging industry

Films: Food packaging film, shrink film, stretch film

Plastic Bags: Shopping bags, garbage bags, shipping bags

Rigid Packaging Containers: Bottle caps, buckets, boxes

Building Materials Industry

Pipes: Water supply/drainage pipes, cable sheathing pipes

Sheets: Decorative panels, wall panels

Injection-molded parts: Fittings, fasteners, valve components

Home Appliances & Daily Goods Industry

Appliance housings: TV, washing machine, refrigerator components

Household goods: storage bins, chairs, tables

Toys & stationery: building blocks, pen casings

Medical & Agricultural Industry

Medical consumables: syringe shells, packaging bottles

Agricultural products: seedling trays, agricultural film, woven bags

PP Masterbatch Applications Show

PP color masterbatch is widely used in films, pipes, sheets, injection-molded parts, automotive components, appliance housings, and daily necessities. It meets diverse color requirements while enhancing the appearance and performance of finished products.

Food Packaging Film

Food Packaging Film PP Bottles

PP Bottles PP Injection Molding

PP Injection Molding

Pp Injection Molding Pipes

Pp Injection Molding Pipes Pp Material Medical Consumables

Pp Material Medical Consumables

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.