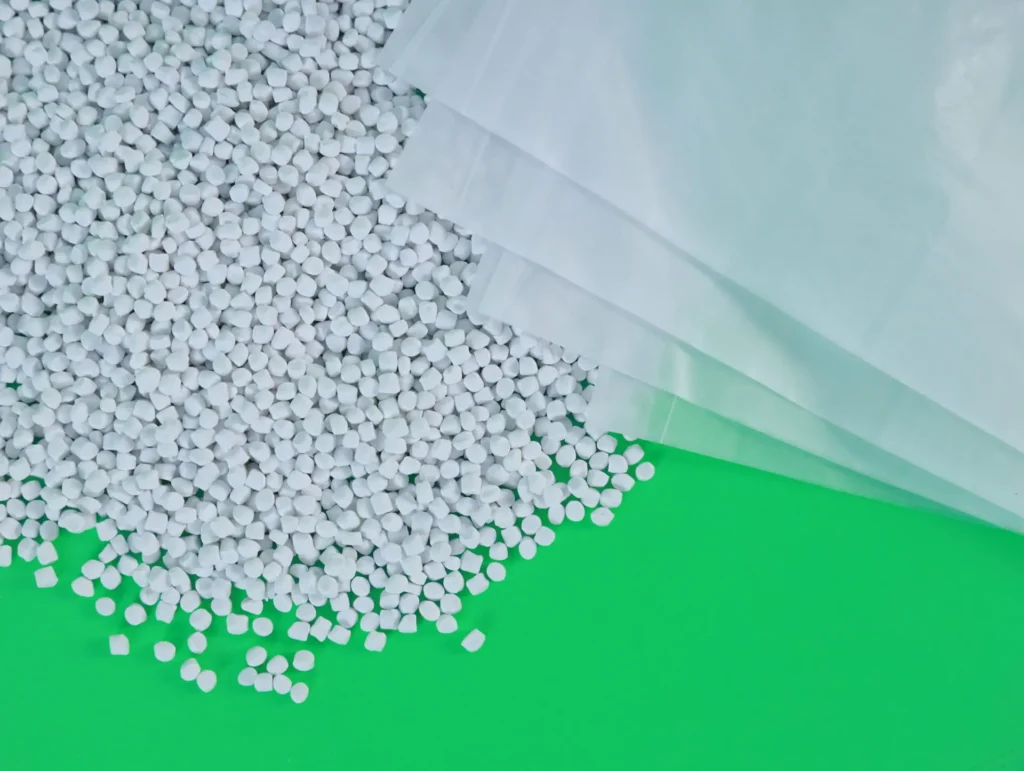

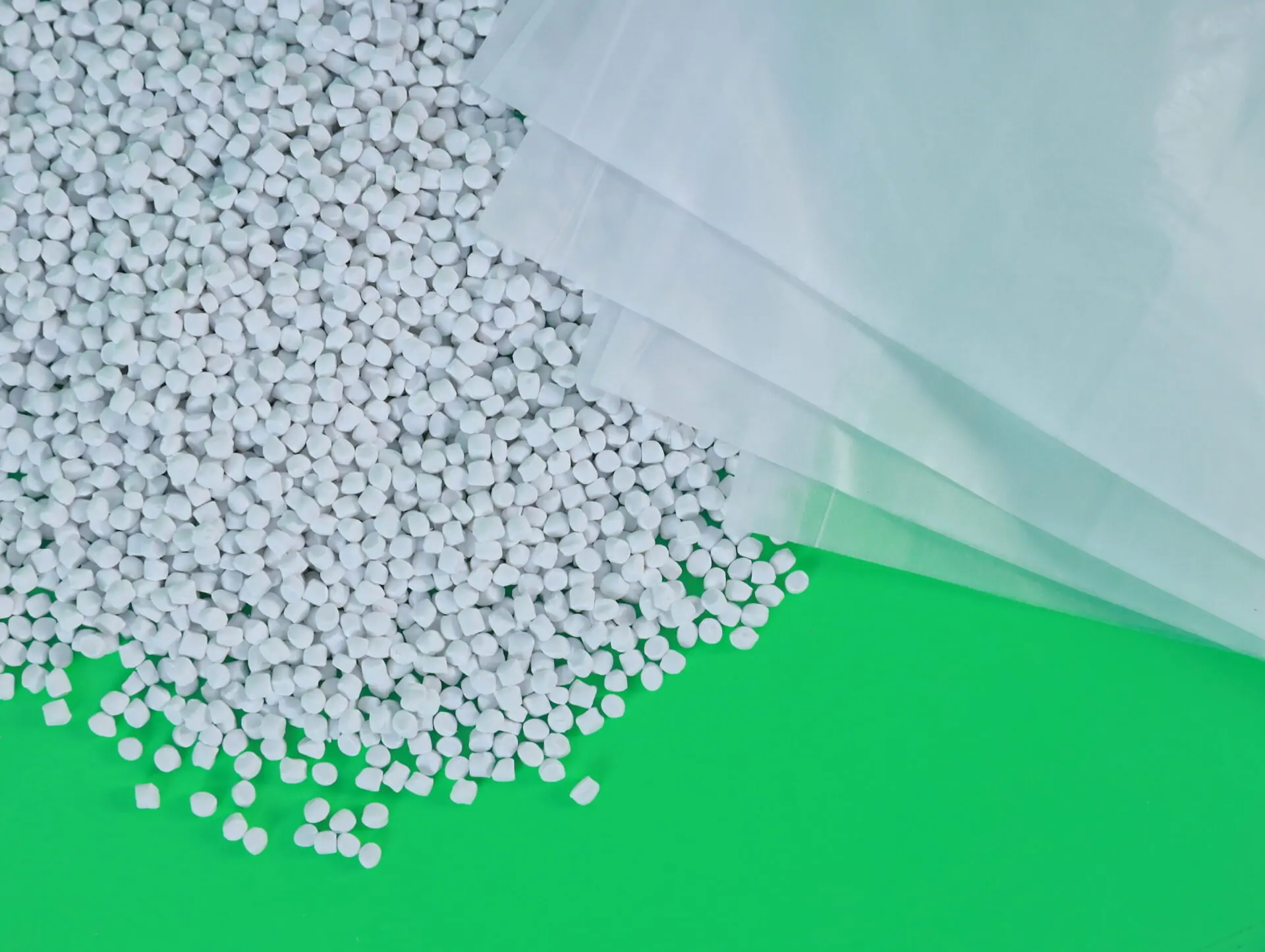

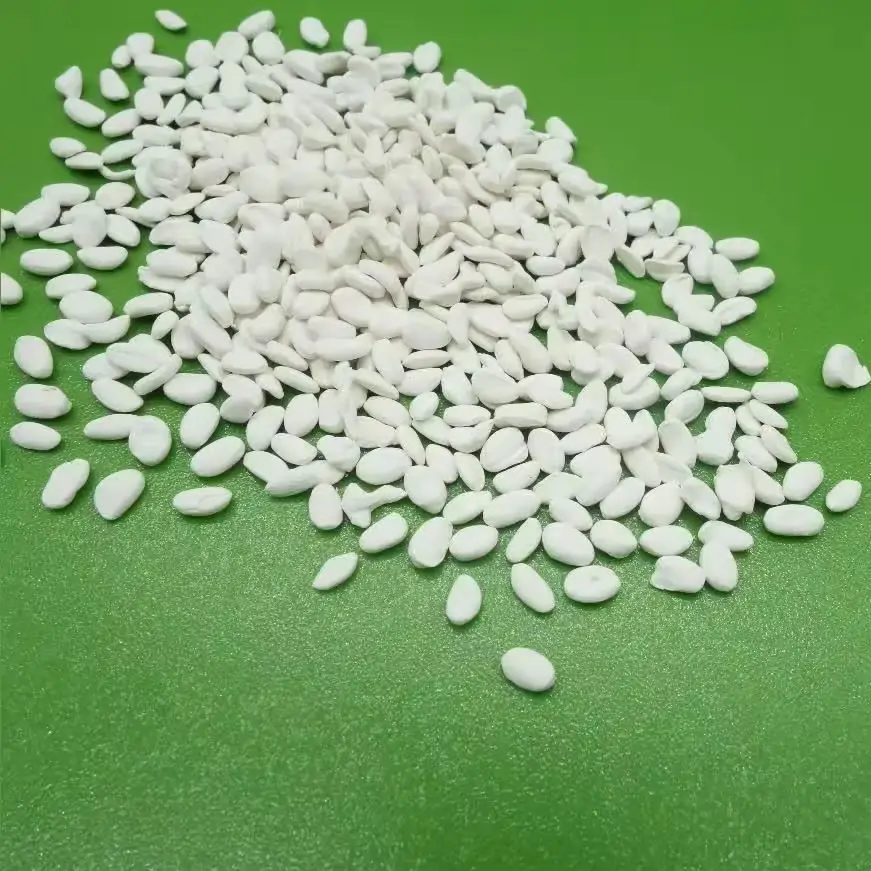

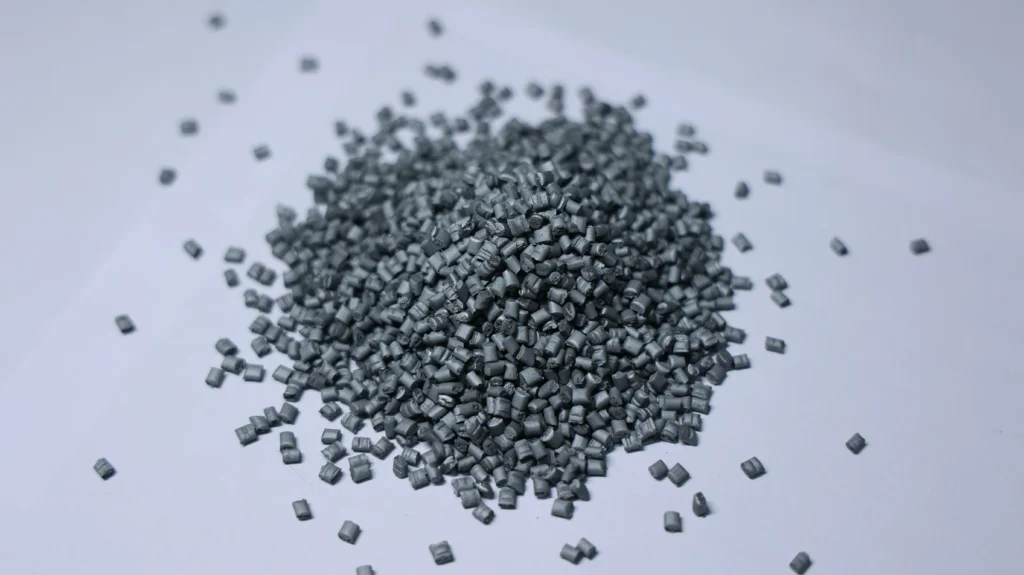

White Masterbatch

White masterbatch is primarily made using titanium dioxide as the main pigment, produced through a twin-screw extrusion process. It features bright color, high color strength, excellent dispersion, high concentration, good whiteness, strong coverage, and reasonable pricing. It also exhibits good resistance to migration and heat. White masterbatch is categorized into general-purpose masterbatch and specialized masterbatch. We can customize colors and provide samples based on your specific requirements, and offer small samples upon request.

- Color pigment: Titanium dioxide/anatase-type titanium dioxide

- Carrier: PE/PP/PS/ABS/PET/TPU

- Dispersing agents: Types include polyethylene wax, oxidized polyethylene wax, stearate salts, etc.

- Functional additives: Brighteners, light stabilizers/UV absorbers, antioxidants, lubricants, release agents, plasticizers, fillers, flame retardants, anti-static agents, anti-fog agents, antibacterial agents/mold inhibitors, biodegradable additives, etc.

Advantages of White Masterbatch

Even and stable coloration

Compared to directly adding powdered pigments, color masterbatches ensure high consistency between batches and more even dispersion.

Convenient to use

Granular form facilitates measurement, transportation, and mixing, reducing dust pollution.

Improved production efficiency

Simplifies the mixing process, shortens mixing time, and reduces material loss during color changes.

Improved product quality

Good dispersion enhances the gloss, mechanical properties, and appearance of the finished product.

48-Hour Custom Color Solution

Cost savings

Although color masterbatches have a higher unit price than pigments, the overall cost is often lower due to precise measurement, reduced waste, improved production efficiency, and lower defect rates.

Environmental friendliness

Reduces dust dispersion, as pigments are encapsulated in resin, lowering the risk of environmental pollution.

Specifications

| Index | Value |

| Resin | PE/PP/ABS |

| Pigment | Rutile titanium dioxide |

| Titanium dioxide content | 20%-70% |

| Mfr 21.6kg\190℃ | 30g\10min |

| Intermiscibility | PP,PP-R |

“White Masterbatch in Different Industries .”

.”

– Enhance pigment characteristics and improve opacity

Home Appliances and Electronics Industry: White masterbatch is widely used in washing machine housings, plastic containers, and other home appliance components, providing pure whiteness and lasting luster while enhancing the product’s anti-aging performance and durability.

Food Packaging and Plastic Sheets: Applied in food packaging films, sheets, and containers, it not only achieves a clean and attractive appearance but also has good weather resistance and safety, meeting the requirements for food contact materials.

Automotive Manufacturing: Used in automotive interior components, exterior parts, and functional assemblies, providing consistent white coloration while enhancing the material’s UV resistance and mechanical strength.

Medical and Electronic Devices: Applied in medical instruments, device housings, and electronic product components, ensuring high cleanliness, excellent coverage, and superior processing stability.

Optimizing productivity and costs

White master batch improves the opacity and coverage of films, sheets, and molded products, and is suitable for flexible and rigid packaging as well as industrial applications. By reducing the amount of polymer and titanium dioxide used, manufacturers can improve efficiency or reduce costs.

White Masterbatch For Blow Molding

White Masterbatch For Building Materials The Application Of White Masterbatch In Food Packaging Film

The Application Of White Masterbatch In Food Packaging Film

White Masterbatch In The Home Appliance Industry

White Masterbatch In The Home Appliance Industry White Masterbatch For Electronic Products

White Masterbatch For Electronic Products

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.