PE Masterbatches

PE Masterbatch (Polyethylene Masterbatch) is a plastic masterbatchs formed by uniformly dispersing pigments, additives, and modifiers within a polyethylene carrier through high-temperature melting. It modifies the color, properties, and production costs of finished plastic products through pigments and additives, making it one of the most commonly used modification materials in plastic manufacturing.

- Colors: PE Black Masterbatch, PE White Masterbatch, Custom Colors (based on customer-provided samples or color charts)

- Additives: Antioxidants, Antistatic Agents, Flame Retardants, UV Stabilizers, Slip Agents, Antibacterial Agents, etc.

- Application Processes: Modification, Blow Molding, Injection Molding, Extrusion, Filament Drawing, and other plastic production processes.

- Package: 25KG/BAG, 26 tons per 20ft container

- Leadtime: 7 days after order confirmed

- Payment Terms: T/T,, L/C

Three Types of PE Masterbatchs

PE masterbatch primarily consists of three main types: color masterbatch, functional masterbatch, and filler masterbatch. Different types of PE masterbatch can be flexibly selected based on industry and application requirements.

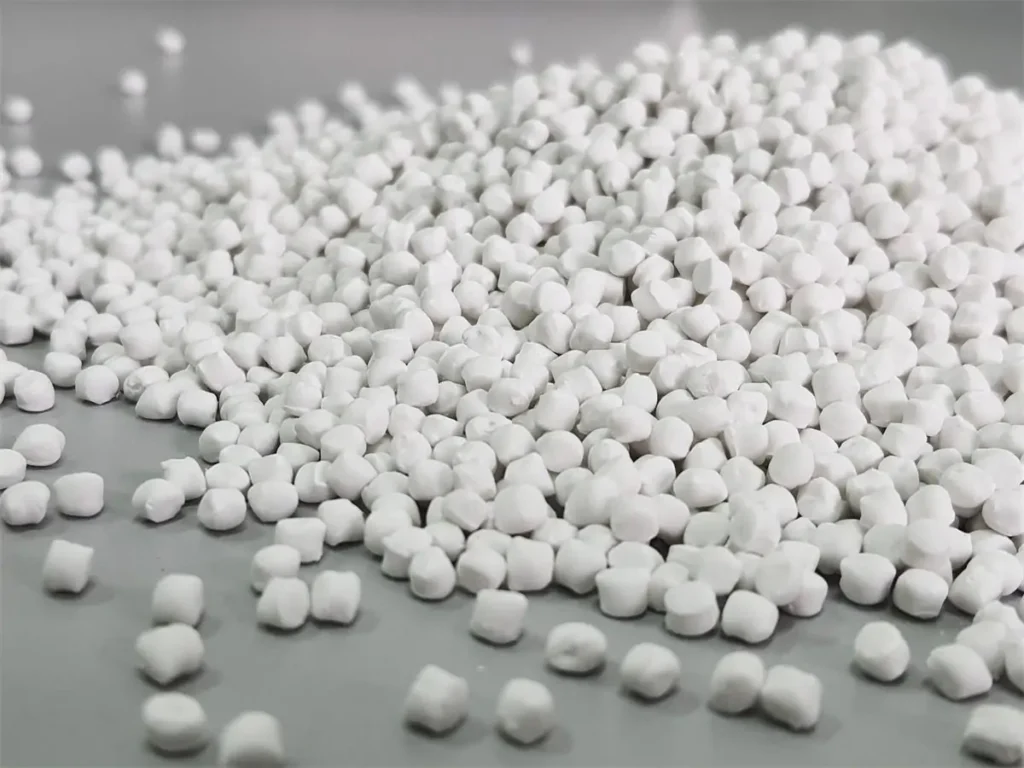

Color Masterbatch

Focuses on coloring, such as PE black masterbatch, PE white masterbatch, and colored masterbatch. Commonly used in packaging, toys, and consumer goods.

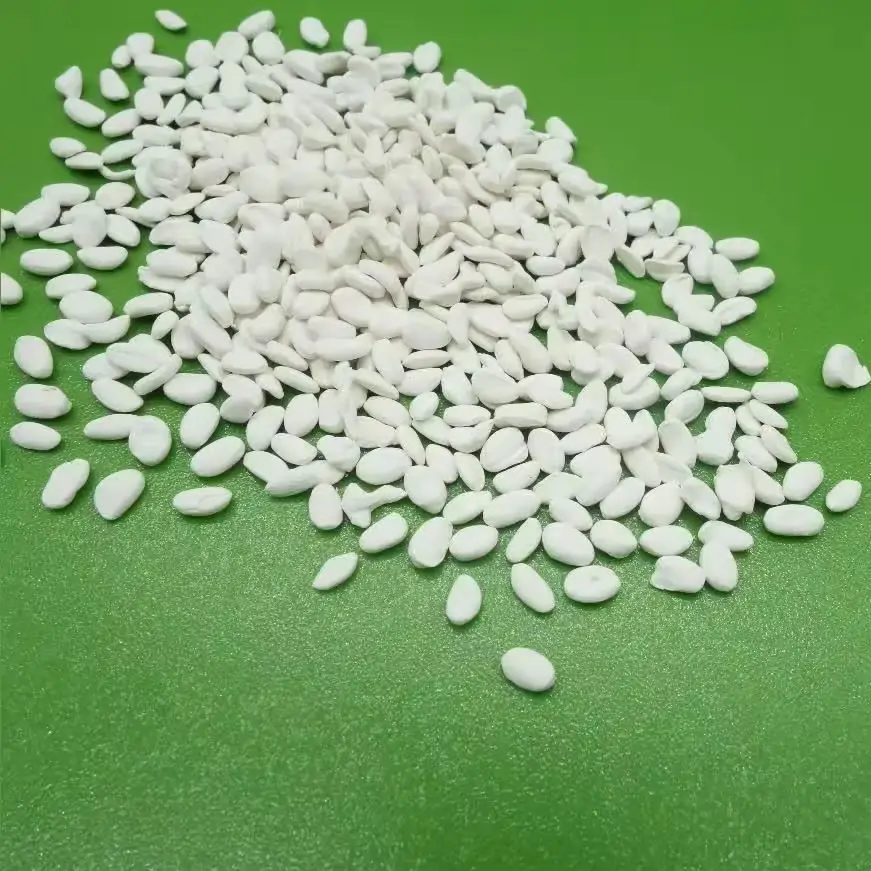

PE Filler Masterbatch

Contains minerals like calcium carbonate (CaCO₃) or talc to reduce production costs and enhance mechanical properties such as strength and stiffness. Widely used in manufacturing plastic bags, films, and packaging materials.

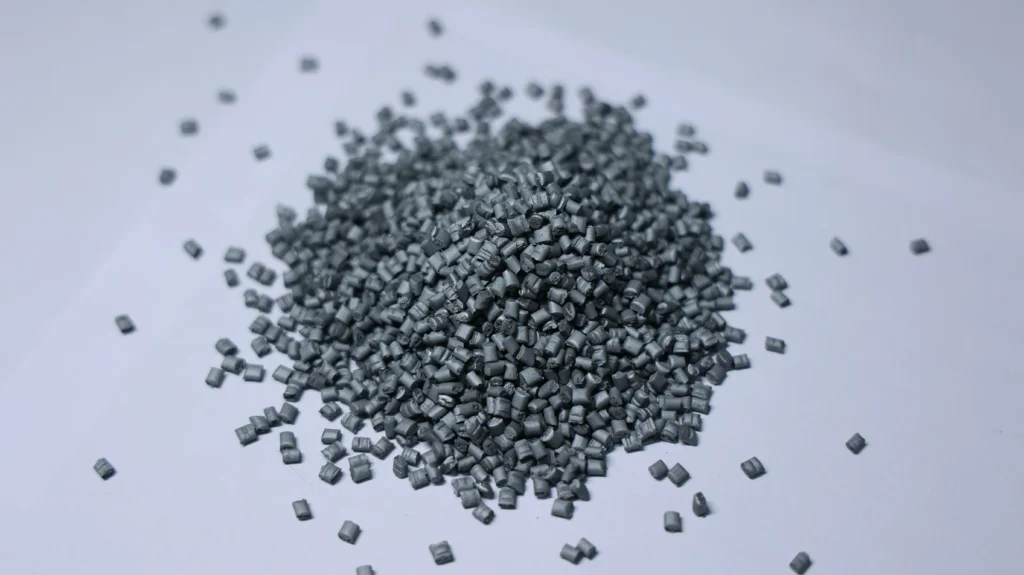

Functional Masterbatch

Utilizes PE as a carrier and incorporates additives like antistatic agents, flame retardants, UV stabilizers, and antimicrobial agents to impart new functionalities. This creates specialized masterbatches such as antistatic masterbatch, flame-retardant masterbatch, UV-resistant masterbatch, and antimicrobial masterbatch, thereby enhancing the competitiveness of plastic products.

Advantages

- Even Dispersion: Excellent color dispersion allows achieving desired color effects with minimal addition, eliminating dust pollution and uneven dispersion issues associated with direct use of powdered pigments.

- Cost Reduction: Compatible with CaCO₃+PE filler masterbatch. Its high energy characteristics enable achieving well-dispersed finished products with minimal granule usage, improving yield rates while reducing production process waste and raw material consumption.

- Simplified Process: The granular form facilitates easy measurement and mixing. It can be directly blended with PE base materials in specified ratios without additional grinding or dispersion steps, boosting production efficiency and streamlining processes.

- Stable Performance: The masterbatch undergoes efficient melt blending and uniform dispersion during production, ensuring thorough pigment distribution and enhancing color consistency and stability in finished products.

- Functional Integration: Simultaneously achieves coloring and functional enhancements (e.g., UV resistance, flame retardancy), streamlining production and increasing product value.

- Environmental Compliance: Utilizes eco-friendly carriers and additives, meeting RoHS, REACH, and other environmental standards. Suitable for stringent applications such as food contact and medical use.

PE Masterbatchs Characteristics

Polyethylene (PE) is non-toxic and odorless, making it an ideal material for manufacturing various daily-use and industrial products.

- Excellent chemical stability: Resistant to acids, alkalis, and organic solvents, with low reactivity.

- Superior toughness: Maintains good flexibility at low temperatures with strong impact resistance.

- Excellent processability: High flowability, easy to form, suitable for diverse processing techniques.

- Low cost: Raw materials are readily available, with overall costs lower than most engineering plastics.

Specifications

| Test Item | Specification Data |

|---|---|

| Appearance | Uniform color,no impurity |

| Color | Black, White, Custom Colors (Pan tone,RAL card) |

| Particle Size | 2.0×3.0 |

| Carrier | PE |

| Moisture (%) | ≦0.1 |

| Heat Resistance (℃) | 160-350 |

| Transference Resistance | 4-5 grade |

| Light Resistance | 4-8 grade |

Customized pE Masterbatches

Custom PE color masterbatch requires the following information from you:

- Final product type: e.g., blown film, injection molded parts, pipes, fibers, etc.

- PE base material used: e.g., LDPE, LLDPE, HDPE, or specific grade.

- Target color standard: Provide Pantone color number, RAL color number, or physical color sample.

- Color fastness requirements: Such as migration resistance, lightfastness (UV resistance), heat resistance rating.

- Processing method and temperature: e.g., film blowing (160-200°C), injection molding (180-220°C), etc.

- Special Functions: Require additional properties such as antistatic, antioxidant, or flame retardant?

Our color experts will contact you within 2 hours to provide complimentary color matching solutions and comprehensive technical support!

“PE Masterbatchs in Different Industries ”

”

– PE color masterbatch is widely used in the following fields

Plastic product manufacturing

Used for coloring various plastic products such as packaging bags, bottles, containers, and pipes, enhancing product appearance and market appeal.

Plastic pellet preparation

Production of vibrant, stable-performance colored plastic pellets supplied as raw material to downstream plastic processing enterprises.

Injection molding

Uniformly blended with polyethylene resin to ensure consistent color and aesthetic appeal in molded parts, boosting product competitiveness.

Building materials manufacturing

Used in producing colored plastic sheets, pipes, and other construction materials, offering strong weather resistance and ease of cleaning and maintenance.

PE Masterbatchs in Plastic

The main function of PE color masterbatch is to provide precise, uniform coloring and functional modification for various plastic products. It features vibrant hues, excellent dispersion, and ease of use, while offering environmental and cost advantages.

PE Plastic Packaging Bags

PE Plastic Packaging Bags PE Wide Mouth Bottles

PE Wide Mouth Bottles PE Storage Container

PE Storage Container

PE Rubber Granules

PE Rubber Granules PE Pipes

PE Pipes

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.