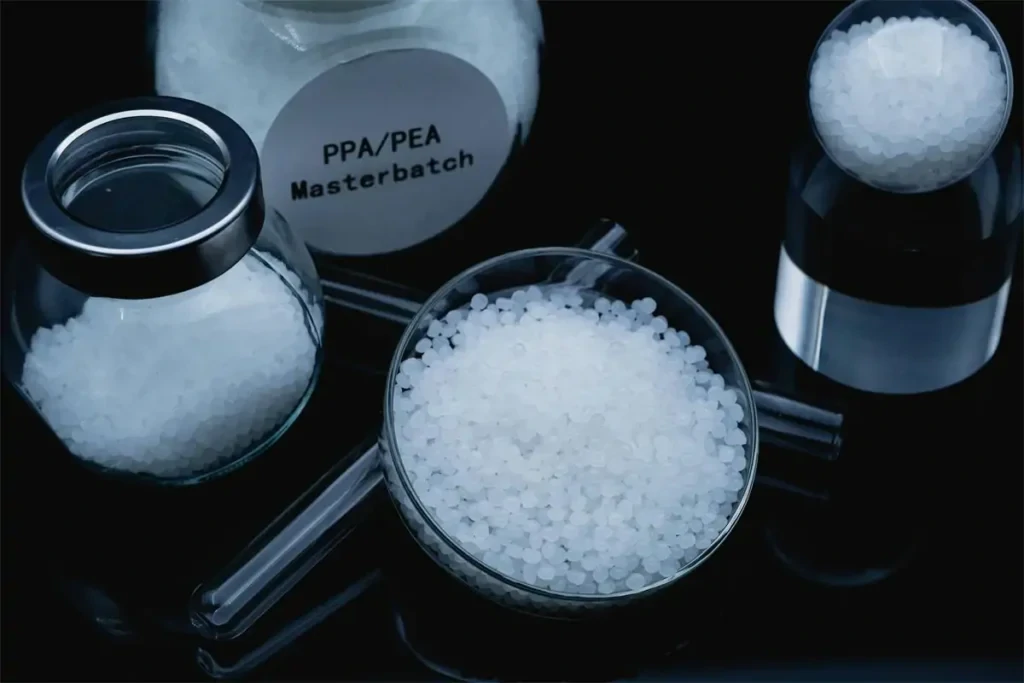

PPA Masterbatches

PPA masterbatch is a functional masterbatch based on fluoropolymers or high-efficiency processing aids, designed to enhance the processing properties of polyolefin materials such as PE, LLDPE, and PP. Polymer processing aid masterbatch reduces melt fracture and sharkskin effects while improving the surface quality of films and pipes.

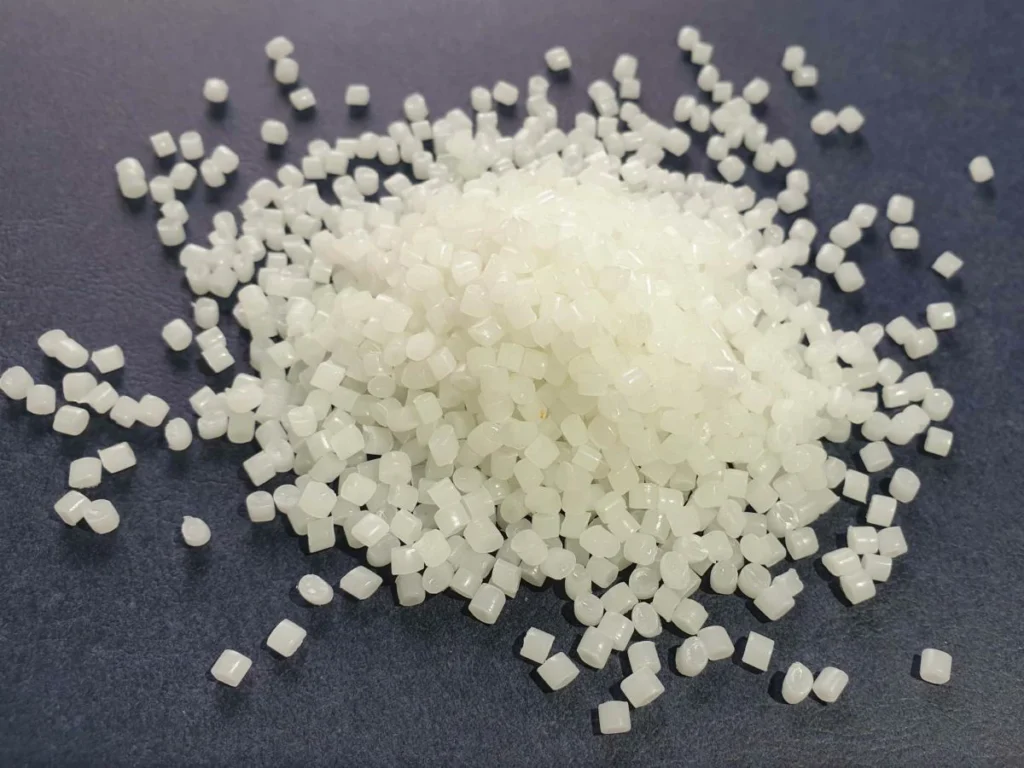

- Color: Translucent or off-white pellets

- Additives: Fluoropolymers, high-performance processing aids, lubricants, etc.

- Process Applications: Blown Film, Cast Film, Pipe Extrusion, Sheet Extrusion, Blow Molding, Wire & Cable Extrusion

- Minimum Order Quantity: 1 ton

- Sample: Free 1 kg sample

- Customization: Acceptable

- Delivery Time: 7 days after order confirmed

- Payment Terms: T/T, L/C

PPA Color Masterbatch Mechanism

The fluoropolymer in PPA color masterbatch forms a uniform, durable lubricating film on the metal surfaces of the extruder barrel and die. This significantly reduces the friction coefficient between the melt and metal, stabilizing melt flow, minimizing melt fracture, and markedly improving film surface finish. Simultaneously, the reduced flow resistance enhances extrusion efficiency and equipment processing stability.

Advantages

- Enhance surface texture: By forming a lubricating film on the inner wall of the die, it reduces friction between the melt and the metal surface, reducing melt fracture and shark skin phenomena.

- Enhance surface gloss and flatness: Improves melt stability for more uniform flow, resulting in smooth, lustrous film surfaces free of weld lines and ripples.

- Reduce extrusion backpressure: Lowers screw backpressure by minimizing friction resistance during extrusion, enabling smoother operation and lower energy consumption.

- Improved Screen Change Pressure Fluctuations: Lubrication reduces filter resistance, enabling smoother screen changes with smaller pressure variations, enhancing filtration stability and production continuity.

- Adjustable with diverse extrusion equipment: PPA delivers stable flow performance for high-speed blown film machines, multi-layer co-extrusion lines, or narrow-slit dies, mitigating melt instability caused by extrusion speed variations.

- High cost-effectiveness: Typically, a low addition rate of 0.5–2% forms a stable lubricating layer, improving processing performance and reducing overall manufacturing costs.

- Excellent compatibility: Compatible with color masterbatches, filler masterbatches, anti-blocking agents, slip agents, recycled materials, etc., without affecting extrusion processing performance.

- Less impact on mechanical and aesthetic properties: Lubricates equipment die surfaces without altering the resin’s inherent physical properties or transparency.

PPA Masterbatch Usage Instructions

- Direct Mixing: Dry blend PPA color masterbatch with raw materials such as PE, LLDPE, HDPE, or PP according to the specified ratio. No additional equipment or process adjustments are required.

- Recommended Dosage: Typically 0.5–2% forms a stable lubricating layer. Increase slightly for high-speed film blowing or high-pressure equipment.

- Lubrication Film Formation Phase Required: Initial addition requires approximately 10–20 minutes of extrusion to allow PPA components to form a continuous film inside the die for optimal results.

- Excellent compatibility with other masterbatches: Compatible with color masterbatches, filler masterbatches, anti-blocking masterbatches, anti-static masterbatches, recycled materials, etc., without affecting product processing performance.

- No additional adjustments required: PPA master batch functions effectively within standard extrusion temperature ranges without requiring increased temperatures or screw speed modifications.

Specifications

| Test Item | Specification Data |

|---|---|

| Product name | PPA masterbatch |

| Appearance | Uniform color,no impurity pellets |

| Color | Semi-translucent or white |

| Particle Size | 2.0×3.0 |

| Carrier | PE/LLDPE / HDPE / PP |

| Primary Component | High-efficiency fluoropolymer processing aid |

| Heat Resistance (℃) | 160-350 |

| Recommended Dosage | 0.5–2% |

| Melt Flow Rate | 5g/10min |

| Suitable Processes | Blown Film / Cast Film / Pipe Extrusion |

| Packaging | 25kg/bag (OEM/ODM supported) |

Customized pPA Masterbatches

Custom PPA colour masterbatch requires the following information from you:

- Final product type: e.g., blown film, injection molded parts, pipe, sheet etc.

- PPA base material used: e.g., LDPE, LLDPE, HDPE, PP or others.

- Target color standard: Provide Pantone color number, RAL color number, or physical color sample.

- Color fastness requirements: Such as migration resistance, lightfastness (UV resistance), heat resistance rating.

- Processing method and temperature: e.g., film blowing (160-200°C), injection molding (180-220°C), etc.

- Special Functions: Require additional properties such as antistatic, antioxidant?

Our color masterbatch experts will contact you within 2 hours to provide complimentary color matching solutions and comprehensive technical support!

“PPA Masterbatchs in Different Industries ”

”

– PPA color master batch is widely used in the following fields

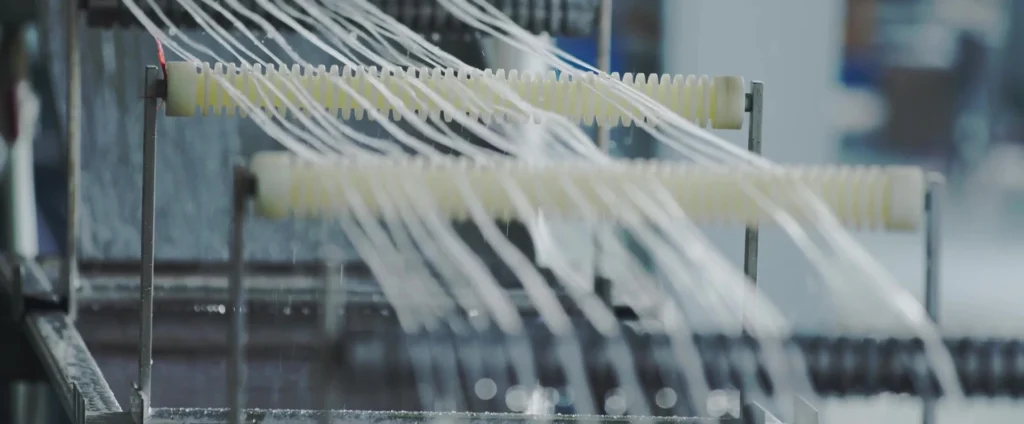

Blown Film Industry

Suitable for LLDPE/LDPE/HDPE film production, such as packaging film, supermarket bags, and agricultural film.

Improves melt flow, reduces melt fracture (Shark Skin), and enhances film surface smoothness.

Cast Film

Used for high-transparency films like food packaging and electronic packaging films.

Improves film thickness uniformity, reduces friction, and increases production line stability and speed.

Sheet Extrusion

Used for cold/hot-formed sheets, packaging sheets, etc.

Reduces melt pressure fluctuations, enhances surface gloss, and improves processing stability.

Blow Molding

Commonly used for hollow containers, lubricant bottles, and cosmetic bottles.

Reduces melt adhesion between the screw and mold walls during processing, minimizing thickness profile variations.

Pipe Extrusion

Used for PE water supply/drainage pipes, gas pipes, agricultural irrigation pipes, etc.

Improves surface roughness issues in high-pressure resin extrusion and increases extrusion efficiency.

Wire & Cable

Suitable for PE/XLPE cable compound extrusion.

Reduces material adhesion in the die head, improving insulation layer smoothness and uniformity.

PPA Masterbatchs in Plastic

PPA masterbatch improves the flow and surface quality of polyolefins during extrusion processing, enhancing processing efficiency and the surface finish of products. It also offers advantages such as low dosage, excellent compatibility, and suitability for multiple processes.

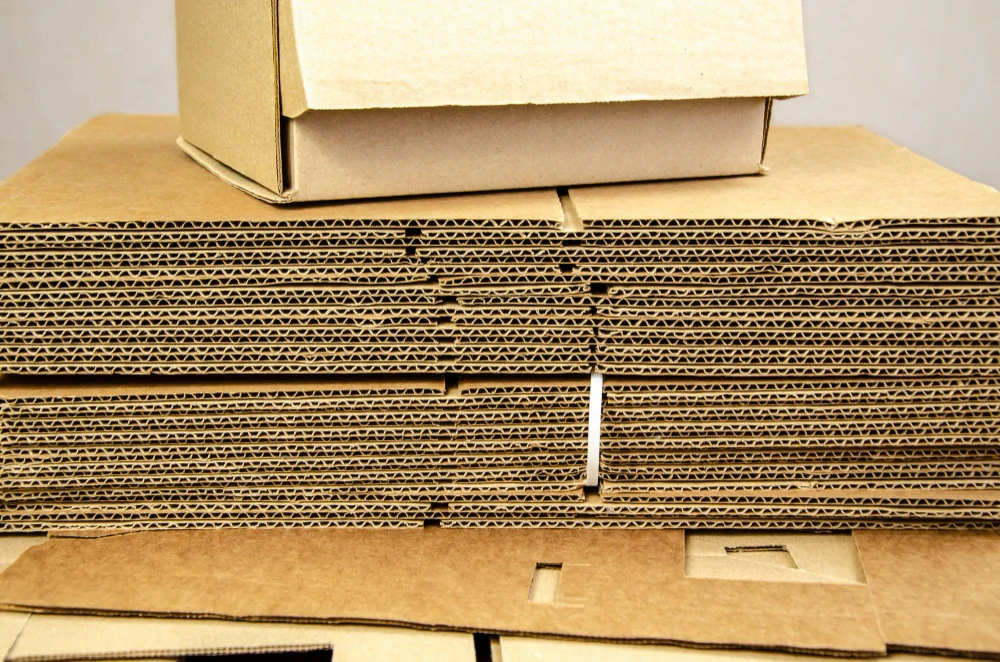

Corrugated Plate

Corrugated Plate Lubricant Bottles

Lubricant Bottles PPA Food Packaging

PPA Food Packaging

Agricultural-Plastic-Films

Agricultural-Plastic-Films HDPE-Pipes

HDPE-Pipes

FAQS

Hot Products

Related Articles

Free Color Matching Service

Huashuo is a professional masterbatch factory and supplier with advanced pilot mixing production lines and comprehensive testing laboratories to support formula development and mass production needs. We combine spectrophotometry technology with professional visual assessment to establish a standardized color matching process, providing customers with efficient and stable customized color solutions. Please contact our technical team for exclusive color matching support and sample services.